- The test solution by National Instruments helps lower the total cost of test while providing efficient results

- The software-based platform improves system reliability and maintainability with built-in troubleshooting tools

The increase in automotive electronic systems has increased the complexity of electronic control units (ECUs) in modern consumer vehicles. Together, a network of more than 100 ECUs comprise the “brain” of a modern vehicle, which power all the innovations concerning vehicle safety, connectivity, efficiency and comfort.

The increase in automotive electronic systems has increased the complexity of electronic control units (ECUs) in modern consumer vehicles. Together, a network of more than 100 ECUs comprise the “brain” of a modern vehicle, which power all the innovations concerning vehicle safety, connectivity, efficiency and comfort.

ECUs improve safety with the help of automatic emergency braking and lane departure warning systems. These controllers also provide more precise engine control, thus offering more performance from the same internal combustion engine.

Therefore, the need to test each controller becomes more important than ever before. However, as ECUs (and the features they support) become more advanced, testing also grows more complex.

To address this challenge, National Instruments (NI), has introduced its ECU Test System, a software-based platform for testing automotive ECUs.

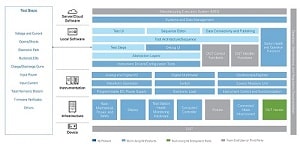

The ECU Test System (ECUTS) is a solution that combines standardization with the flexibility to deliver efficiency in tester development, maintenance and test time. NI has integrated the first level of common components into a standardized test architecture to save customers time in the development process and to simplify tester maintenance. Because of the modular PXI design, testing is flexible and can scale across a range of body, chassis and powertrain ECUs (based on the instrumentation selected). In addition, high-performance hardware (powered by TestStand) can help reduce test time. As many as four DUTs can be tested in parallel with a single test system.

Increased benefits

ECUTS helps lower the total cost of test and set suppliers up for success by:

- Accelerating development with a higher level starting point. The Systems R&D team has already integrated instrumentation, cabling, loads, switching and a mass interconnect into a core rack so customers can focus on building the right test sequences to thoroughly test ECUs.

- Standardization on a global architecture for functional test of body, chassis and powertrain ECUs. The benefits range from leveraging standardized comprehensive service programs to reusing operator training courses, to being able to correlate data across sites.

- Reducing test cycle time by testing up to four ECUs in parallel.

- Reducing the risk of downtime through improved system reliability and maintainability with built-in troubleshooting tools and global service programs that streamline repairs and exchanges.

“Partnering with NI to solve our ECU functional test challenges has lowered our total cost of test while maintaining high-quality standards,” said Sergio Mejia, I&IE test engineer at Vitesco Technologies. “By standardizing on NI testers, we reduced cycle and development time, increased system re-use and made debugging, deploying and maintenance easier.”