Strong legislative laws need to be framed by government authorities for mandatory recycling of solar energy system waste instead of landfilling, considering the massive 75,00,000 tons of waste that is likely to be generated until 2050. Solar module recycling is not yet commercially viable and is a net cost for the industry

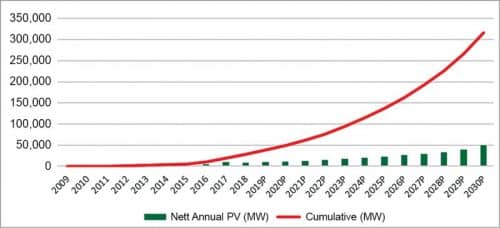

Solar energy is seen as a key element to address the issues of climate change. The compelling political commitments and declining costs are resulting in rapid market development from just 1GW of solar photovoltaics (PVs) in 2012 to 30GW in 2019 India. It has emerged as the third largest solar PV market in the world after China and the US with a cumulative installed capacity of over 28GW as of 2018. Fig. 1 shows the year-on-year market growth of solar PV installations and projections until the year 2030.

In solar thermal sector the cumulated solar water heater installed capacity is little over 14 million square metres but is now largely dominated by evacuated tube collectors.

The Indian government has set an ambitious target of achieving 100GW solar PV and 20 million square metres of solar thermal by March 2022. Further, the solar PV power installed is likely to touch 350GW by 2030 and ultimately 1,000GW by 2050.

It is estimated that cumulative PV module volume will grow little over 8.5 million tons by 2025 and little under 20 million tonnes by 2030. With such robust growth to occur not much attention has so far been paid to module recycling in India.

The three principles of waste management are: reduce, reuse, and recycle. Owing to India’s ambitious target of solar power generation reducing e-waste is a limited option and hence the 3 R’s can be renamed as recycle, reuse, and regenerate.

Solar PV mass estimation

The global market is dominated by crystalline silicon (c-Si) PV modules with almost 98% market share with the rest being thin-film modules. India is virtually 100% c-Si market. Similarly, in comparison to the solar PV modules the flat plate collectors that also use glass and aluminium are insignificant. Hence the focus for end of life management will be focussed on the c-Si PV modules.

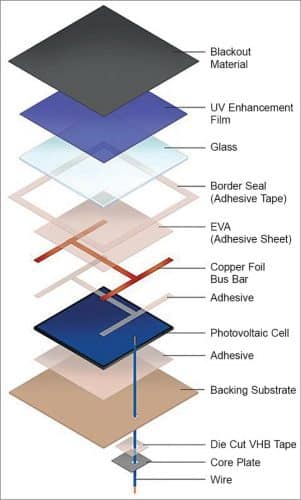

The typical material composition of a c-SI PV module, excluding the aluminium frame, is as shown in Fig. 2.

A solar PV module typically consists of glass, aluminium, copper, silver, encapsulants, semiconductor, and precious metals that can be successfully recovered and reused at the end of their useful life. By mass, today’s typical crystalline silicon PV panels consist of approximately 70% glass, 10% aluminium, 10% polymer (encapsulant and back sheet foil), 3.5% silicon semiconductor, 1% copper, and others including silver (less than 0.1%) and tin.

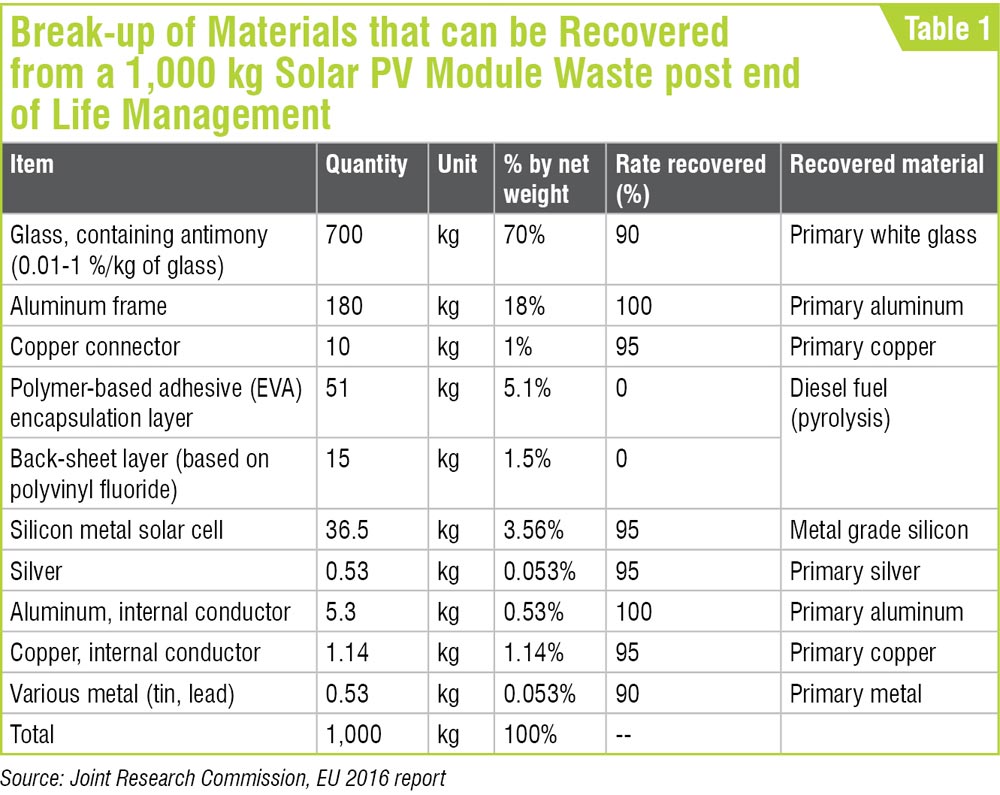

A report by the Joint Research Centre of European Commission gives break-up of the waste materials that can be recycled per 1,000kg of PV waste as shown in Table 1.

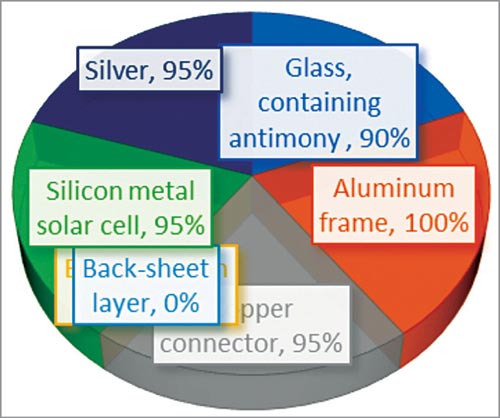

The percentage of material that can be recovered is as shown in Fig. 3.

The percentage of material that can be recovered is as shown in Fig. 3.

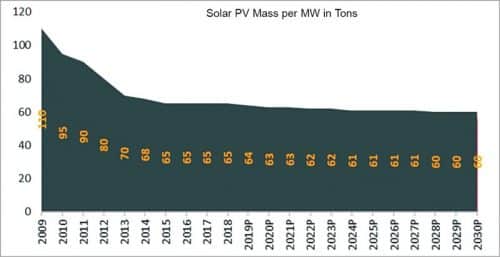

The mass (weight to power ratio) of c-Si PV module is reducing with time as shown in Fig. 4. This is due to further developments in PV technologies such as material savings and improved solar cell efficiencies. This can alter the equation in Table 1 in future.

Hazardous materials

Barring glass, aluminium, and precious metals a typical c-Si solar PV module contains some of the potentially hazardous materials like polymer and antimony in the glass. At the end of life these can have negative environment and health impacts, although the situation is not alarming. The polymer material includes backseat and encapsulant made of ethyl vinyl acetate and poly vinyl fluoride. This material cannot be recovered and is usually incinerated. However, using thermal processing at 500°C, it can be safely evaporated.

When glass is exposed to ultraviolet radiation or sunlight, antimony would leach from the glass when the waste panels get exposed to wet conditions. In March 2019, the Ministry of New and Renewable Energy had made public a draft of the blueprint for its environmentally safe handling, recycling, or disposal.

PV module waste projection by 2050

Usually, modules are warrantied for 25 to 30 years and can last even longer. But as the solar industry has grown, the market has been flooded with cheaply made modules that can break down in as few as five years, which results in early loss. The PV module waste generation is analysed under two scenarios:

1. Regular loss after 25-30 years

2. Early loss due to qualitative issues and re-powering

Under regular loss, all manufacturers stand a guarantee of performance over a period of 25 years with 90% output for first 12 years and up to 80% after 25 years of operation. At the end of 25 years majority of the modules are discarded as they reach the end of their life as waste. In fact, most of them are becoming waste after 20 years itself.

The causes of early loss can be from the following:

- Glass breakage

- J-box and cables

- Power loss

- Delamination

- Transport damage

- Loose frame

- Optical failure

- Defect cell interconnect

- Re-powering with high efficiency cells

As per study undertaken by International Renewable Energy Agency (IRENA) – International Energy Agency (IEA) Photovoltaic Power System (PVPS) programme, the worldwide solar module waste would grow to 78 million metric tons by 2050. The top five countries by themselves will account for about 50 million metric tons as shown in Fig. 5.

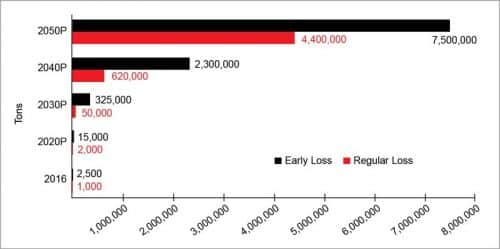

It is interesting to note that India will have the highest early loss and their causes need to be investigated systematically.

Using Fig. 1, the accumulated solar PV waste in India—considering a standard 25-year life under regular loss—can be estimated. However, going by the projections in Fig. 6, it is difficult to estimate the exact volume of waste as it is anticipated many modules may achieve early loss. This thought needs to be examined with specific case to India by undertaking a survey amongst manufacturers. The IRENA-IEA PVPS modelling provides insight on the cumulative solar PV waste under regular and early loss scenarios as shown in Fig. 6.

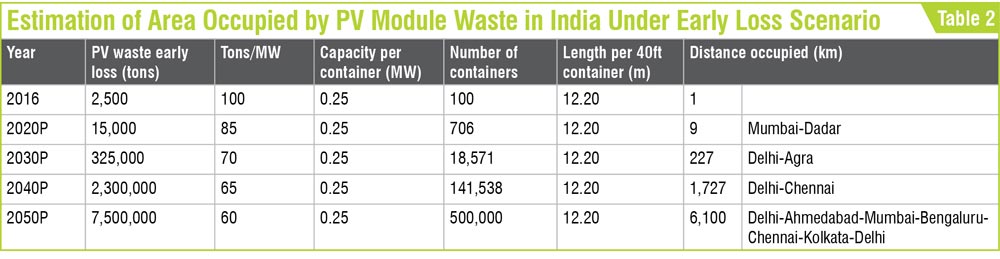

If these PV module wastes are left lying under the early loss scenario then considering standard 12.2-metre (40 feet) container the distance occupied will be as below in Table 2.

Material-wise projection of waste in India

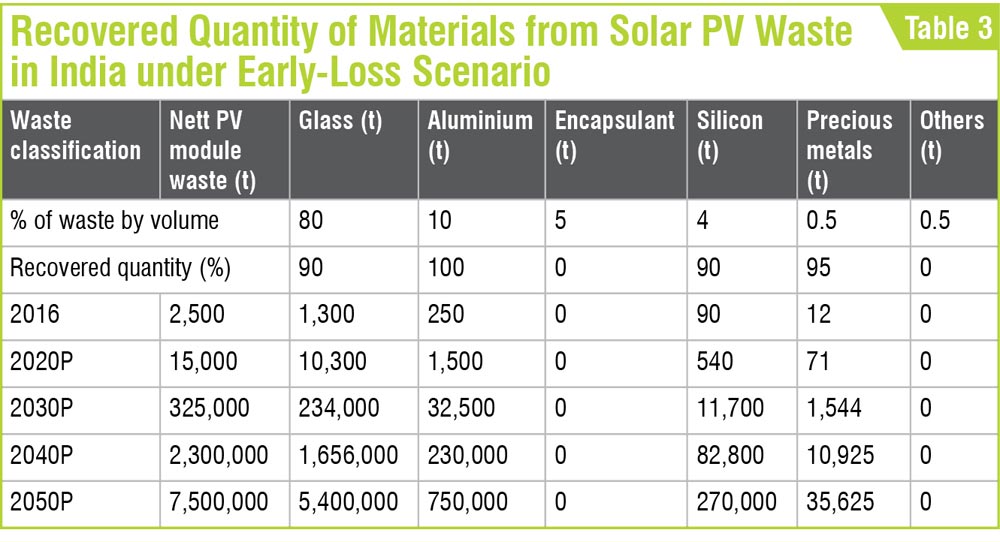

Table 3 shows the recovered quantity of materials from solar PV waste in India under early-loss scenario post their end of life.

International regulations

International regulations

At present, only the European Union (EU) has adopted and pioneered PV-specific waste regulations. Most countries around the world classify PV panels as general or industrial waste. In limited cases, such as in Japan or the US, general waste regulations may include panel testing for hazardous material content as well as prescription or prohibition of specific shipment, treatment, recycling, and disposal pathways.

The EU, however, has pioneered PV electronic waste (e-waste) regulations. Directive requires all producers supplying PV panels to the EU market (wherever they may be based) to finance the costs of collecting and recycling end-of-life PV panels put on the market in Europe. Lessons can be learned from the experience of the EU in creating its regulatory framework to help other countries develop locally appropriate approaches.

Action plan for future

Following actions can be taken to address the solar waste management issue:

- Policy guidelines to address the solar waste management like the Waste Electrical and Electronic Equipment (WEE) directive in European Union because the components of solar modules are not all made of biodegradable materials.

- All manufactures of solar PV modules must build in a value of recycling cost mandated by a legal framework.

- Identify causes of early loss occurring in India and measures to prevent.

- The legal framework must foster PV recycling more as a recuperate raw material for producing new modules than tagging it as a hazardous component.

- Analyse the net amount of greenhouse gases avoided in making of a new PV module against recycling waste PV modules.

- Undertake further research to make the entire recycling mechanism adequate and economically viable compared to landfilling.

- Owing to vast geographic area, portable recycling system must be developed for logistic management.

- Estimate the quantum of re-production of PV modules from waste material.

- The disposal of recycling solar PV module must rest with the end-user as survival of module manufacturers in their lifetime may be doubtful.

- Analyse additional job opportunities generated from recycling PV modules.

Conclusions

Strong legislative laws will need to be framed by government authorities for mandatory recycling of solar energy system waste instead of landfilling, considering the massive 75,00,000 tons of waste likely to be generated until 2050. Solar module recycling presently is still not commercially viable and is a net cost for the industry. Recycling technology will have to be made economical, considering the transportation costs and minimal cost for scrap. The recovery rate should be aimed near 100% and useful to make new PV modules. The entire recycling must have zero environmental impact. Participation of producers of solar panels will be crucial to ensure the entire recycling value chain is easy. Recycling solar PV waste has potential to create enough jobs, hence must be practised.

Jaideep N. Malaviya is managing director, Malaviya Solar Energy Consultancy, Pune