ROHM developed the AC/DC fly-back converter ICs with an integrated 730V breakdown MOSFET the BM2P06xMF-Z series (BM2P060MF-Z, BM2P061MF-Z, and BM2P063MF-Z). These devices are ideal for auxiliary power supply and Switch Mode Power Supply (SMPS) solutions for industrial drives as well as home appliances – including air conditioners, white goods, and factory automation equipment. These fly-back ICs require no additional heatsinks and no discharge resistors and capacitors. It helps designers to shorten design time, simplify the circuitry, reduce cost and increase reliability by offering integrated solutions.

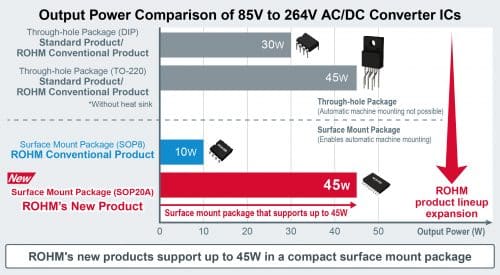

In recent years, AC/DC converters for home and industrial use must not only support 85V-264V AC to accommodate different AC voltages around the world, but also comply with international standards such as Energy Star for energy savings and the IEC 62368 safety standard. It is also important for AC/DC converter ICs to be surface mount to reduce factory mounting costs. However, as high heat/high loss DMOSFETs and planar MOSFETs are still widely used in AC/DC converter ICs, until now it has been difficult to provide tens of watts of output power in a surface mount package.

To solve these issues, ROHM developed new compact surface mount high power 45W models BM2P06xMF-Z. They are equipped with an original low-loss SJ (Super Junction) MOSFET together with optimized PWM control circuitry – facilitating the development of 85V to 264V AC/DC converters. Adopting a surface mount package supports automatic board mounting (which was previously difficult to do in the past). Meanwhile, the implemented functions ensure compliance with the IEC62368 safety standard, even when the discharge resistor (a source of loss during standby) is removed. Additionally, original low standby power control technology is applied – resulting in extremely low standby power consumption. Supply voltages up to 60V (VCC) are also supported – eliminating the need for an external step-down power supply circuit.

Compared to general products with equivalent performance, automatic mounting contributes to lower factory mounting costs. Moreover, ROHM is able to reduce standby power by over 90% along with the number of power supply circuit components by four, contributing to greater power savings and higher reliability in applications.

Going forward, ROHM will continue to deliver greater system energy savings and optimization by not only developing a wide range of power semiconductors and advanced analog ICs, but also by providing optimal solutions for each application.

Key Features

- 45W class surface mount package significantly reduces factory mounting costs

These latest products integrate a low loss (low ON resistance) 730V SJ MOSFET along with both startup and optimized control circuits in a compact high heat dissipation surface mount package (SOP20A). In addition to compatibility with input voltages from 85V to 264V AC, the surface mount package supports high output power up to 45W (24V × 1.875A=45W), which has been difficult to achieve in the past, while significantly reducing mounting costs by enabling automatic mounting not possible with general through-hole types.

- Reduces standby power consumption by 90% or more over standard products

The BM2P06xMF-Z series utilizes a control circuit (X capacitor discharge function) that leverages ROHM’s high voltage process and analog design technologies to meet the safety requirements of the IEC 62368 standard even without a discharge resistor (which is a source of loss but was previously essential). At the same time, original low standby power control technology (which provides optimal control of the switching frequency of power semiconductor and current flowing through the isolation transformer) further reduces IC power consumption during application standby, resulting in a system standby power consumption of just 17mW (at 0W output, 230VAC) – reducing standby power consumption by more than 90% vs general products.

Also included is a noise reduction mode that suppresses noise from the isolation transformer components. This mode can be turned OFF to decrease standby power or be turned ON and adjusted if there is a concern about isolated transformer component noise or a need to minimize the workload for countermeasures.

3. Decreases the number of power supply circuit components by four along with the risk of power semiconductor failure, contributing to higher reliability

These new products support operation over a wide VCC voltage range from 11V to 60V. The maximum power supply voltage of 60V is twice that of standard products, providing superior reliability against external noise and surge voltages. At the same time, it is possible to reduce the number of external step-down power supply circuit components that are typically required by four, while the internal SJ MOSFET which is resistant to surge voltage [featuring an avalanche (breakdown) tolerance more than 30x higher than DMOSFET and planar MOSFETs used in general products] contributes to higher system reliability by reducing the risk of power semiconductor failure.

Application Examples

◇ Consumer electronics such as air conditioners, appliances, monitors, and hair dryers

◇ Industrial equipment including inverters, AC servos, routers, and office automation devices

Suitable for AC/DC converters up to 45W output in consumer and industrial applications