Electrically conductive adhesives (ECAs) claim to possess many superior properties than the widely used traditional solders. With an increasing demand for electronic goods, this decade may see ECAs gradually establish themselves as the new solder.

Proper placement of electronic components, such as integrated circuits and LEDs, on substrates is the crux of developing an operational circuit board for an electronic device.

While conventional lead-free solder excels at its task for rigid PCBs, it is not well suited for emerging applications that require components to be attached to flexible substrates or conformal surfaces.

The most widely used solders are lead based which, in spite of having low cost and good strength to firmly hold electronic components, create health issues after a prolonged use. They have been outlawed in the European Union and restricted to commercial use in other areas of the world. Although lead-free solders are a good replacement, mitigating health risks, they fail to match the strength of their lead based counterparts.

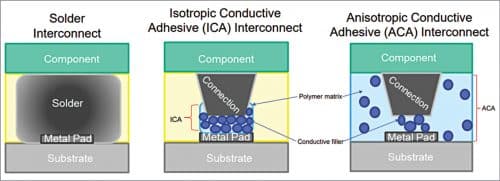

The alternative electrically conductive adhesive (ECA) not only has high strength but is quite safe as well. ECA comes in two types—isotropic conductive adhesive (ICA) and anisotropic conductive adhesives (ACA)—which correspond to different ways of conducting electricity across a joint. ACA is further divided into anisotropic conductive paste (ACP) and anisotropic conductive film (ACF).

Fig. 1 compares the interconnect of a typical solder to an ECA. In an ICA, electricity is conducted in all directions, due to which only a small amount is needed between the connection and the metal pad. An ECA consists of a polymer matrix that holds the conductive filler material in place. The conductive filler material is typically a metal powder that acts as a bridge across the joint in such a way that a connection is made. With respect to placement for proper flow of charges, the ICA is very comparable to the solder interconnect.

Unlike ICA, an ACA conducts charges in only one direction. So, even if it is applied between the entire component and substrate, it will only conduct electricity across the connection—without causing a short circuit.

Some other conductive joining technologies include silver sintering, transient liquid phase sintering (TLPS), and non-lead based solders. Silver sintering requires very high temperatures, making it unsuitable for large commercial applications, similar to TLPS, which is very much on the emerging side of the conductive joining technology. As mentioned earlier, non-lead based solders do not match the lead based solders in strength and are unsuitable for large-scale applications.

Comparison of different die-attach techniques

From Fig. 2 it is evident that lead (Pb) based solder is an ideal technology in every way, except for being extremely toxic—making it highly unsuitable. With a good combination of green and yellow indicators, ECA seems to be an allrounder. Although silver (Ag) sintering and TLPS also give excellent performance, they are not practical in terms of cost and workability.

Alternate Solders fail to give the required performance and reliability, even if they excel as an easy successor to traditional lead based solders at low costs. Amidst all the properties of different die-attach techniques against each other, ECA arguably stands out to have the best potential in this market.

Properties of ECAs

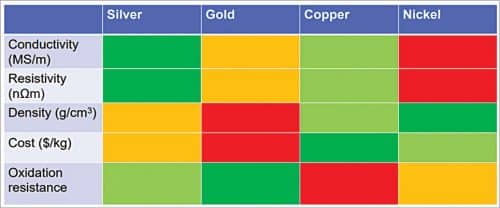

Silver is the most preferred material for conductive filler in ECAs owing to its very high conductivity and reliability. But since it has an extremely high cost, other filler materials can be considered where cost plays a huge decisive role.

Fig. 3 shows that silver meets all aspects, apart from density and cost. Copper, on the other hand, simply oxidises too easily, making it unsuitable. Nickel falls widely short on conductivity but makes up with good filler material density.

It can be noted that gold and silver are the only two materials that have the required conductivity and lack in reactivity. However, gold is an even more expensive alternative to silver. With respect to polymer resin materials, most epoxy based ones are used although other varieties are also useful, depending on the exact application and properties required.

Please register to view this article or log in below. Tip: Please subscribe to EFY Prime to read the Prime articles.