Manufacturing semiconductors is a vital aspect of electronics empowerment that has not yet harvested the potential of Industry 4.0. Can they complement each other and help answer the crisis of semiconductor shortage the world is facing? Sunil Banwari, Vice President, Advantest Corporation, in an interaction with EFY’s Mukul Yudhveer Singh believes that this can create more jobs in the industry.

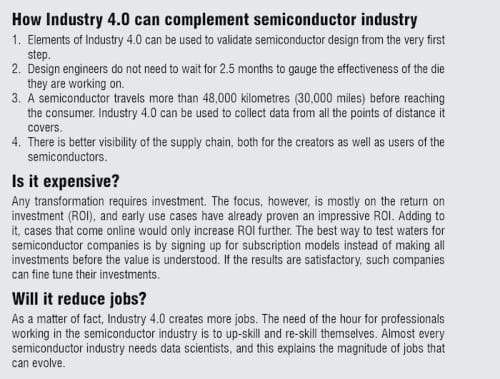

Q. Can implementing Industry 4.0 help us meet the demand for semiconductors, especially with the chip shortage in the world today?

A. Definitely! Many factors are associated with the shortage of semiconductors. For example, in the automotive industry, companies like Toyota have done really well while others have not. What worked for Toyota is the good visibility in the semiconductor supply chain. The automotive manufacturers usually buy modules from Tier 1 organisations, which are usually similar to electronics manufacturing services (EMS) families.

[signinlocker id=”87626″]

The semiconductors and components are bought from suppliers who are two levels below. Which means, the automotive manufacturers are not usually aware of what’s happening in the supply chain until it hits them too late. In such a complex scenario, Industry 4.0 can make a major difference by adopting the semiconductor industry. Even with semiconductors being the driving force behind technologies like artificial intelligence (AI) and machine learning (ML), the semiconductor industry in itself has not seen much of Industry 4.0.

To summarise, semiconductor test solution providers are looking to change this in a way where the semiconductor industry itself is benefitted. It might be important to note that Advantest generates the most amount of data in the semiconductor industry across all players. We are using this data to take the industry to the next level in terms of digital transformation.

Q. Would better visibility in the supply chain be of help?

A. Yes, and that is one of the essential things being worked on today. As an industry, we are trying to build solutions over the cloud that will allow any manufacturer to calculate what’s happening in the supply chain well ahead of time. The solutions will tell manufacturers about problems that can arise in the future, giving them enough time to react and come up with a resolution.

The cloud is one function that we are most excited about. When talking about increasing the yield through a fab, it would take at least a year. But when it comes to establishing a new fab, it could take around two to three years of time. However, with Industry 4.0 in the picture, we can guarantee improved yield starting today. Yet these are just some functions of the Industry 4.0 value chain.

Q. What are the other possible areas where Industry 4.0 can be used in the semiconductor industry?

A. The complexity of the semiconductor manufacturing process requires high levels of visibility, analytics, and awareness. Analytics in the past was mostly manual. Let me explain this through an analogy.

Just like how a multiple-use residential/commercial skyscraper consists of many layers—structures with interdependencies—similarly, a semiconductor device process is like a skyscraper that has many floors or processing layers, as we call them in the industry. It takes 2 to 2.5 months to put these layers onto a device for a typical semiconductor company.

A lot can go wrong in this process. The smallest mistakes can affect the time of the semiconductor to market by weeks, or in some cases months. This in turn affects the overall image of a semiconductor company. What makes the process more challenging is that different layers of the device are being worked upon in different parts of the world. A typical semiconductor travels no less than 48,000 kilometres.

Now all the places a semiconductor goes, tremendous amounts of data is generated. Sometimes it is collected manually as well. The data acquired is in multiple languages, and one of the biggest challenges that we as an industry face is to bring this data under one machine in one language to gauge what’s going right and what’s not.

Industry 4.0 provides the analytics of this data and improves the yields that directly improve the cost. It can also help in answering the questions that are related to the tests of semiconductors. Issues of over testing or under testing can be answered with the help of Industry 4.0. Though there are many more advantages that it offers, the target of most companies is to decrease the time to market for the semiconductors.

Q. What all stages of semiconductor manufacturing can benefit from Industry 4.0?

A. A term often referred to in the semiconductor industry is the Product Life Cycle. It is also sometimes referred to as the Technology Life Cycle. Industry 4.0 can benefit semiconductor manufacturing at every stage of the product or technology life cycle as it gives us an opportunity to do things in a smarter way.

Smart Manufacturing, when used as a synonym to Industry 4.0, includes smart design capabilities too. Designing a product today requires going through different iterations of the same. These different iterations go on until you hit the right spot and can meet all the expectations from the design. Typically, it takes multiple iterations to get one design right.

Industry 4.0 reduces the number of iterations dramatically. AI and ML being the biggest contributors play a big role here. The best example of the same is the recent announcement made by Google.

When you do a layout of a chip it requires a lot of designing, and the layout engineers have to ensure that the circuit is placed in a way that optimises the efficiency of a chip. Thankfully, Google has introduced a tool which can do the same using AI instead of humans.

According to Google, the tool decreases the time to market and helps bring down the cost by decreasing the amount of time and number of iterations required in the process. This was just an announcement by Google and, personally, I do not think it has been adopted widely in the semiconductor industry. However, we should not forget that Google is designing its own chips.

There is a tool that we at Advantest offer that can decrease the time of validation of silicon. This tool is also based on Industry 4.0 and basically allows one to do a proper validation with every iteration and hence improve performance with every new iteration. It can even suggest design options on its own.

Q. Any other elements where Industry 4.0 can be beneficial to the semiconductor industry?

A. Consider the example of an OSAT or an ATMP that manufactures chips for others but does not have its own design, say someone like the Taiwan Semiconductor Manufacturing Company (TSMC). The opportunity that Industry 4.0 provides to them helps improve the yield and capacity. Typically, the margins of such companies are lower than those that design the chips.

Industry 4.0 can provide the reasons behind losses in terms of capacity at each step for OSATs and ATMPs. It can also reduce the idle time caused by different reasons (including equipment not working) by suggesting what to do based on data it has collected in the past.

With much of the process being manual, it takes weeks to improve yield because the data is read, the equipment is reset and tested, before the final steps are taken. Industry 4.0 can automate the process, saving valuable time as the data is available with you at every point of time and process, and it does not need to be analysed manually.

Q. What about the yield part?

A. As mentioned earlier, the usual process of semiconductor manufacturing, which used to be about two-and-a-half months long in the past, made it difficult as we had to wait to find out whether the die being used was good or not. It involved a lot of guesswork with the usual question being, “What percentage of what was started would be good after two-and-a-half months?”

Imagine working on a cake for two-and-a-half months and then finding out that the customer is not happy with the cake. You will either have to start the whole process again or leave it for a new cake. Considering the same in the world of semiconductors, Industry 4.0, on the other hand, has the capability of signal corrections that are needed to be made at each stage during these two-and-a-half months. This opportunity Industry 4.0 provides can help dramatically improve die yield.

Q. But isn’t implementing Industry 4.0 expensive for the already expensive semiconductor industry?

A. Investment is indeed a big and core topic for everyone. The best way to predict the prospects of the investment is to start with the subscription services. That way you can easily set short-term goals, track results, and determine the ROI, which will guide and justify additional investments. As a matter of fact, at Advantest we advise our smaller customers to start with the subscription model first. This way it becomes part of the operating expense (OPEX) for a company.

I think the best way to find out if something is expensive or not is by calculating the amount of investment in terms of return on investment (ROI). There’s always a payback period involved. It varies from company to company but typically, if the ROI stretches over decades, you can conclude that it isn’t a good investment.

Q. Would the subscription services require the provider to go to the client locations physically?

A. One of the key benefits of Industry 4.0 lies in providing services virtually. A lot of the things can be done virtually. At the end of the day, it is the clients who know their machines best. Advantest encourages customers to come up with their own set of applications, and the required training would definitely be looked into.

The semiconductor market is highly competitive, and survival clearly goes to the fittest. Our data shows that companies that are technologically ahead are also ahead in time to market, when compared to their competitors. Though, there is no standard on the adoption of Industry 4.0, it all depends on the maturity of the company as well. Some companies are lagging and have not adopted even the Industry 3.0 features, which places them at a competitive disadvantage.

The decision of adopting Industry 4.0 must come from the executive level. The ROIs are not related to one business aspect but affect multiple businesses throughout the entire company. It is good to know that almost all leading companies in the semiconductor industry have taken initiative in Industry 4.0 domain and this was done at the executive level.

Q. Would the implementation of Industry 4.0 in the semiconductor industry result in shrinkage of jobs?

A. That fear, in my opinion, is very overrated. Every country and every company is trying to improve its better living index. For every job that is being replaced there are multiple jobs being created by the same industry. The biggest example of this is the number of data scientists required in the industry. The designation data scientist did not even exist a few years ago.

Industry 4.0 generates big data and at Advantest we are still in the process of gathering data in terms of gigabytes per die. Much of this data was not being looked at in the past, and there can be instances where important data is not even collected. Industry 4.0, in terms of the semiconductor industry, is creating more jobs.

[/signinlocker]