Thanks to photocurable polymers, EPFL researchers have shown a light-based 3D-printing technology that is around 30 times faster than traditional additive manufacturing, producing items in 20 seconds that would ordinarily take more than 10 minutes.

Unlike traditional 3D printing which involves placing blobs of material on a substrate and allowing (or causing) them to solidify, EPFL’s light-based technology, which was first introduced in 2017, utilises a completely new and considerably faster approach.

“We pour the resin into a container and spin it,” says Christophe Moser, a professor at the EPFL’s Laboratory of Applied Photonic Devices. “Then we shine light on the container at different angles, causing the resin to solidify wherever the accumulated energy in the resin exceeds a given level. It’s a very precise method and can produce objects at the same resolution as existing 3D-printing techniques.”

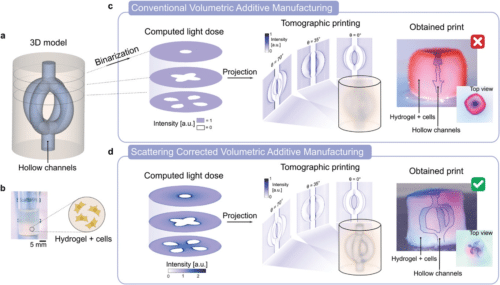

Until now, the problem with this technique was that it could only be done with transparent resins, because anything with colour in it, such as the opaque resins used to make artificial arteries in the biomedical industry, would bend and distort the light as it passed through, resulting in a drastic loss of resolution and some pretty sad-looking printed objects.

However, in new study, Moser and his colleagues describe a technique that allows the use of opaque resins by calculating the path of light through the resin using a video camera placed behind the resin. After studying the light that got through, the team was able to develop a distortion correction algorithm, which they used to apply to the print instructions while the machine ran, ensuring that the exact amount of energy was sent to each location.

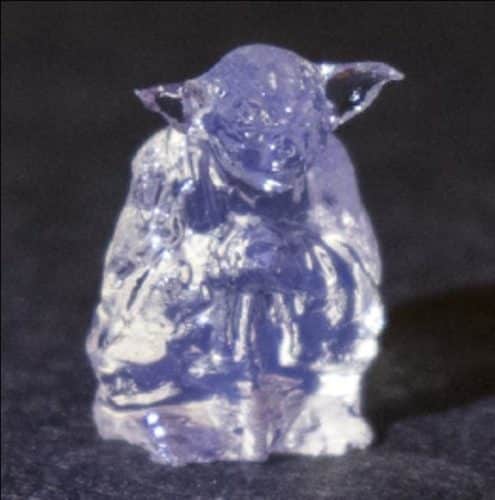

According to the crew, the printed pieces in opaque resin are still incredibly rapid to construct – a little printed Yoda took about 20 seconds to make. They also have a resolution of around one-tenth of a millimetre, which is similar to that of transparent resin. The team is currently working to raise the resolution by a factor of a hundred, with the goal of achieving micrometer-level precision.

Their entire study can be found here.