The biggest advantage of 3D printers today is rapid prototyping. At times, 3D printers could be the right equipment for low-batch production than going for traditional manufacturing. “3D printers started being used as geek tools and are now shaping up as user-friendly tools; even my eight-year-old daughter uses one for her school projects,” says Vishal J.C., CEO, Grey Sim Ltd.

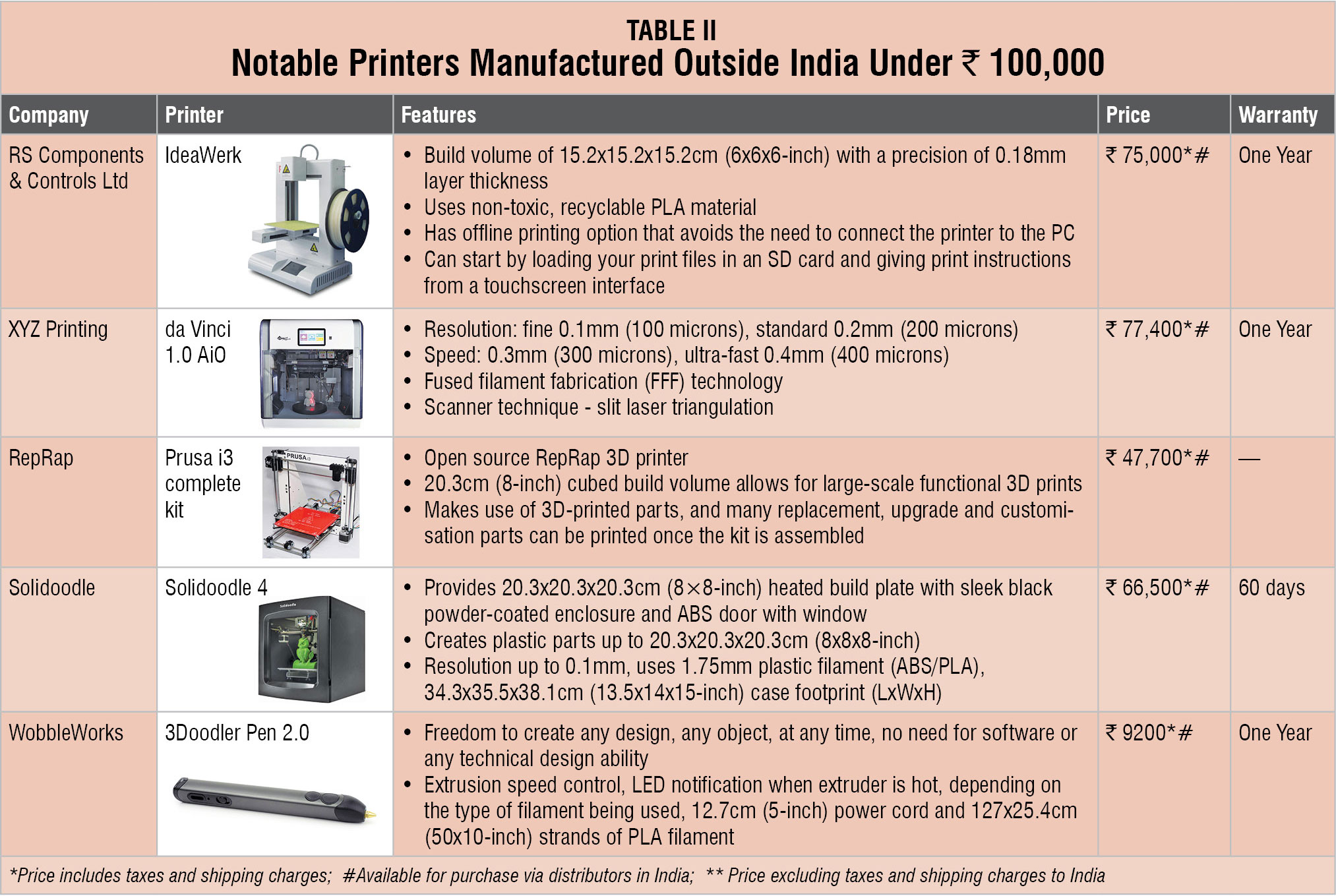

Shiv Bhambri, CEO, RS Components & Controls Ltd, feels, “3D printers are ideal for anyone who wishes to explore the fascinating world of 3D printing, build prototypes or even carry out small volume production.”

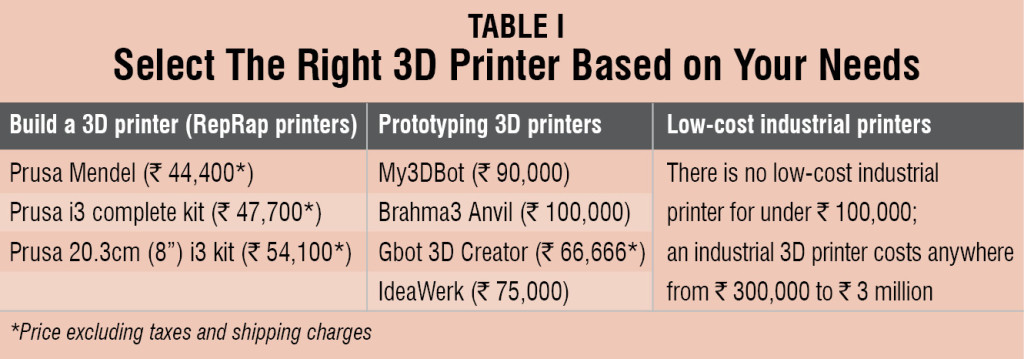

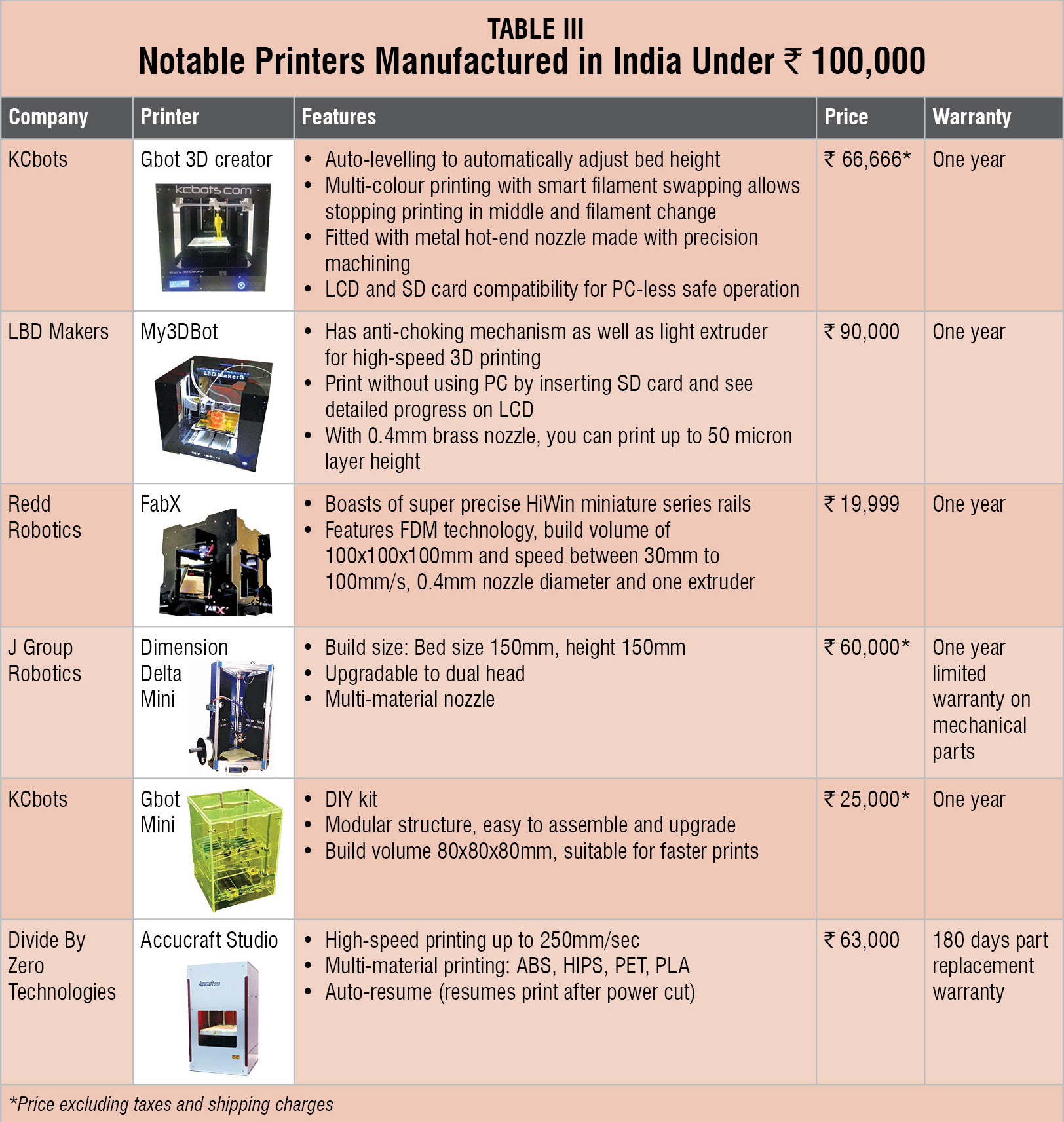

In this article, we particularly focus on 3D printers under Rs. 100,000 and attempt to help you make the right choice.

Generalising the family of 3D printers, Raja Sekhar Upputuri, co-founder, Think3D, notes that there are three kinds of 3D printers. “First, basic printers coming at an entry price point with very low build volume and a single extruder; second, medium range printers with decent build volume and single or dual extruders; and third, printers with high build volume used for semi-industrial and semi-professional applications, which, of course, come with a higher price tag.”

Upputuri says, “Companies that started with basic printers are venturing into the other two categories, and vice versa. Customers have a variety of options to choose from today. In fact, some vendors are introducing stripped-down, economical versions of 3D printers available for as low as Rs. 30,000.” Although these printers might not provide professional-grade experience, these are mostly used for educational purposes by schools and colleges.

What is new in 3D printers under Rs. 100,000

The only technology being offered for 3D printers under Rs. 100,000 is fused deposition modelling (FDM). “The major advancement happening with respect to FDM is scaling down of the cost of 3D printers using this technology,” informs Prudhvi Reddy, co-founder, Think3D.

“For printers within or even slightly exceeding the price tag of Rs. 100,000, there are plenty of options available to choose from. This is mostly because of the stabilisation of FDM technology, but there is no major breakthrough in the printers as of now,” Reddy adds.

Considering this price range, differences in 3D printers available in the market are with respect to parameters such as build volume, price, number of extruders or underlying chips that make movements faster (speed of the printer).

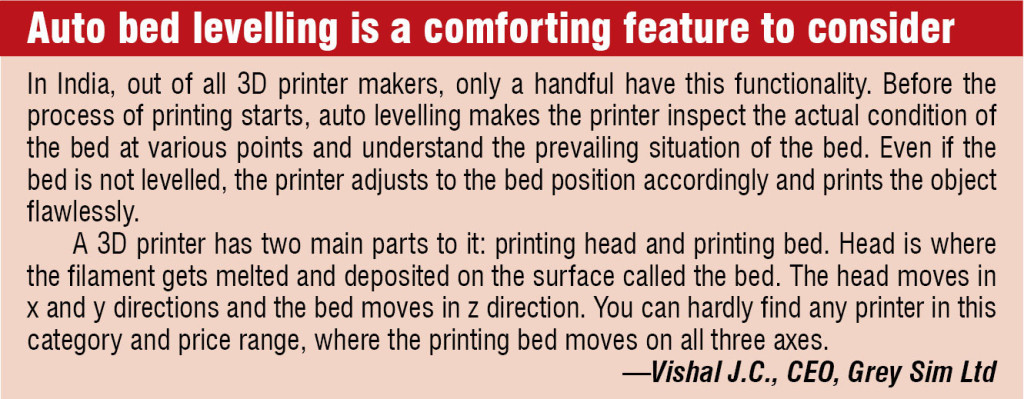

Coming to technological advancements, the fundamental approach remains the same, especially for printers under Rs. 100,000. Nitin Gandhi, co-founder, LBD Makers, says, “For printers within this price range, recent notable additions have been Wi-Fi connectivity, auto bed levelling, Bluetooth connectivity and dual nozzles.”

Upputuri says, “There is a rise in the speed and number of extruders for a 3D printer.” He adds, “Earlier dual extruder printers were costly but today these are available for less than ` 100,000. This is mostly because of the increase in volume and stabilisation of FDM.”

Apart from automated bed levelling and wireless connectivity being embedded into 3D printers, Nikhil Chowdary, technical head, Design & Prototyping Centre, ESCI – The Institution of Engineers (India), says, “Online support, all-metal nozzle, partially-enclosed build chambers and portability/collapsible construction are some other features provided by manufacturers. Modular 3D printers are encouraging customisation. Also, direct light processing (DLP) technology is finding a new foothold and will be a strong competitor for FDM only in jewellery making and micro-electronics prototyping.”

He adds, “Some manufacturers are introducing accessories like acrylonitrile-butadiene-styrene (ABS) spray for bed preparation and spray to smoothen printed parts, along with 3D printers.”

Locked or open printers—the choice is yours

Broadly speaking, FDM printers available in the market can be divided into two groups: locked 3D printers and open 3D printers, informs Reddy.

In locked 3D printers, the whole printer is a locked system and the customer has to purchase the same company’s filaments, whereas in the case of open 3D printers, a buyer can purchase 3D filaments from any available brand.

Reddy says, “Both come with their own share of advantages and disadvantages. If a buyer prefers to go with a locked printer, he or she should check if filament supply and after-sale service is available.”

Filament is the input, consumable material for a 3D printer. To make a 3D model, the filament is melted and deposited in layers based on the design supplied to the printer. Filament for a 3D printer is as essential as an ink cartridge is for a 2D printer.

Reddy notes, “In locked-filament 3D printers, a chip is embedded in the filament such that the printer recognises only the filament manufactured by the same company or an authorised company.”

About 80 per cent to 85 per cent of printers in the market are open printers, for which one can buy the filament from different vendors. Printers such as Ultimaker or UP BOX are open printers. Most Indian manufacturers are making open printers.

Build volume, after-sales service, output quality and speed important parameters to consider

For printers priced under Rs. 100,000, an important parameter to consider before buying is the build volume of the printer.

Next would be the number of extruders(single or dual). Reddy says, “Most printers in the Indian market come with one or two extruders only.”

Accuracy, speed and resolution of the printer are also crucial. He adds, “These are highly interdependent parameters because if accuracy is higher, speed can be lower.”

Vishal points out that, currently, speed is a misleading parameter to look for in FDM 3D printers under Rs. 100,000, because almost all printers have similar speeds. “We have to keep in mind that 3D printer is a rapid prototyping machine and not a substitute for mass production. It will boost conventional mass production as more ideas get physical manifestation, thereby increasing desktop manufacturing,” he says. “Reliability is another important factor to consider,” he adds.

Gandhi feels that quality of the printed object and corresponding speed are the most neglected factors while purchasing a 3D printer. He says, “The quality is dependent on speed. Very low speed could correspond to high quality. Therefore the buyer should not question the resolution but at what resolution does the printer achieve a given speed.” Cost and size of acquisition also matter.

Automated bed levelling, multi-material printing and nozzle design are some other factors to keep in mind. Chowdary says, “Metal-body-constructed printer is recommended, and portability is important if repeated movement is required.” If you plan to import a printer from outside India, he adds, “packaging for the shipment is critical. It makes a massive difference as 3D printers lose calibration during transport.”

Printing material is also of utmost importance. “Buyers prefer the 3D printer to be able to make designs in all materials, and most manufacturers even claim so. But there is a difference between what it can and what it will actually 3D print. Most multi-purpose nozzles get choked with polylactide (PLA), which is a major material used for 3D printing,” says Gandhi.

He adds, “So the focus should not only be on the number of different materials that can be used but also how effectively it can 3D print one material without the nozzle getting choked. It took us a while to make an anti-choking nozzle for MY3DBOT for ensuring good customer experience.”

Vishal also feels that the user should not be looking at the number of filaments that a printer can use but acceptance of any kind of filament.

Another important parameter, which is not quantitative, is ease of use and after-sales service. Reddy says, “It is important for manufacturers to address any queries or issues faced by the buyer.”

Closed versus open printers is another vital parameter to keep in mind. In fact, Vishal feels that support is the first and foremost parameter that a customer should look for before buying a printer. He says, “Service and support is the most vital factor.”

Vishal adds, “There must be some kind of assurance in case a problem arises. The company must be able to sort it out by sending a technically-qualified person onsite.”

Choosing between closed and open is ultimately the buyer’s choice. Upputuri notes, “If you are willing to pay a premium for your peace of mind, then go for a closed 3D printer, else an open 3D printer is a better option. As a company in 3D printing space, we have inclination towards open 3D printers.”

Bhambri feels customers should focus mostly on parameters that save cost in terms of specifications and accessories. He says, “Reducing downtime, efficiency and ease of printing are other focus parameters.”

For schools and universities, do-it-yourself (DIY) 3D printers are apt because of ease of use, learning, and of course, low price point.

Price trends

In the last few years, cost of FDM printers has come down drastically, feel industry experts. Upputuri says, “In the past, printers sold for Rs. 300,000 are now being sold for around Rs. 100,000. In the next one year or so, these printers could even be available for less than Rs. 50,000.”

Chowdary too feels that prices of 3D printers are falling as more entrepreneurs are taking the path of manufacturing 3D printers based on open source technologies. He says, “Today, manufacturers are competing on price with very few providing value-added features.”

Developments for future

Currently, objects printed using 3D printers are mostly display pieces; these are not functional. In the near future, you will be able to print a prototype with electronic components like sensors or chips and metallic elements such as screws and ball bearings, informs Reddy.

For instance, he says, “It is possible to print an object up to a certain level, place all electronic and metallic components and resume printing. It is also possible to print up to certain layers, place components at regular intervals and create a fully functional prototype.”

He adds, “Once this functionality becomes commercial, it will be a revolutionary change on the FDM side of 3D printing.” As of today, Mark One is the only printer that makes fully functional assemblies using carbon-fibre materials.

Mass-automated 3D printing hubs with lowered costs of laser based 3D printing and multi-colour 3D printing using different technologies will be some other important additions in the coming years, feels Chowdary.

“The best technology that we foresee is continuous liquid interface production (CLIP) in which oxidation is used for binding,” informs Gandhi.

He adds, “This technology is 20 to 100 times faster than FDM. Instead of making products layer by layer, it makes multiple layers together, increasing the strength of object.”

Food printers are slowly entering the market. “Two years down the line, we can foresee food printers emerging in the market,” feels Upputuri.

There is also a lot of research on various kinds of materials that can be used to 3D print and on different scanning techniques. He adds, “We also see better technological advancements in digitally acquiring the shape of a 3D object.”