Electric motors and drives are important components of industrial automation. Their selection therefore is an important step in the process of building an automated system. You as a buyer must know what types of motors and drives are available and suitable for your application.

The most common electric motors are meant for machine tools, special motors for industrial robots, blowers, fans, power tools and pumps. In industry, motors and drives powering mechanical equipment account for about 65 to 70 per cent of the total energy consumed. Reducing this figure is of prime importance for developing energy-saving systems. The longer the drives and motors are in operation, the higher the savings required.

Broadly, there are two types of motors: AC motors and DC motors. Within these categories, there are sub-divisions and various variations.

AC motors

Here, the current is alternating, and so the motor will run but only at sine-wave frequency. Given below are the two types of AC motors:

Asynchronous induction motors. Induction motors are regularly used for constant-speed and adjustable-speed drive applications. These are popular for automated industrial applications including general-purpose and inverter/vector duty. Two variations of induction motors are single- and three-phase.

Synchronous AC motors. These are three-phase AC motors that run at synchronous speed without a slip. Unlike induction motors, these are not self-starting, and have to be run up to synchronous speed by some means before these can be synchronised to the supply.

These motors are used when load keeps changing and speed is critical. These are mainly used in constant-speed applications. With inverters and cycle converters, these can be in used in variable-speed applications.

Single-phase AC motors. These are small-size motors used in domestic applications like fans, hair dryers, washing machines, vacuum cleaners, kitchen equipment, blowers, small power tools, dairy machinery, small farming equipment and so on.

There are some special types of induction motors, construction wise, built for applications in different working conditions.

Wash-down motors, for instance, are designed for applications where a lot of water is splashed or directed on and over motors. These are suitable for food processing, pharmaceuticals and packaging applications.

Hazardous-duty motors are used where the potential for igniting the environment exists. These are explosion-proof since their design contains provision for any internal failure within the body of the motor. Classification of hazardous areas falls under IS:5572:2009 and IS:5571:2009.

Severe-duty motors are designed for harsh industrial-processing applications. Features include protection against contamination, moisture, vibration and demanding duty-cycles. These are commonly found in foundries, pulp and paper plants, chemical plants, petro-chemical industries, mining and waste management, among others.

Farm-duty motors are designed for high starting torque and moderate starting current. These are available in single- and three-phase type. Typical applications are in dairy, poultry and irrigation pumps.

DC motors

These are two-wire (power and ground) continuous-rotation motors. Range of DC motors for industrial application includes normal DC, servo and stepper motors. Nearly all DC motors used for automation are of brushless DC motor (BLDC) type.

Most of these run at a high rpm. Reduction in speed is achieved through gears (DC geared motors). BLDC motors can also be used with electronics sensitive to electrical and radio frequency interference because these do not cause a significant amount of either.

Servo motors. Servo motors are generally an assembly of four things: DC motor, gearing set, control circuit and position sensor (usually a potentiometer). These do not rotate freely, instead, angle of rotation is limited to 180 degrees (or so), back and forth. These are used where the position needs to be defined accurately, such as controlling the movement of a robotic arm or leg within a certain range.

Stepper motors. These are digital motors whose rotation is in steps defined by the step angle. Stepper motors, unlike traditional AC or DC motors, do not rotate smoothly. Each step occurs sequentially, never concurrently. Capable of rotation in both directions and precision angular incremental changes, these are more expensive than other AC or DC motors and require the use of more expensive drives, motor control systems and programming.

Applications for stepper motors include automated wire-cutting machines, robots, machine tools, precise fluid or temperature-control devices, high-speed pick-and-place machines and many other types of equipment that require very precise speed and load control.

Universal motors

These are a special type of motors designed to run on either DC or single-phase AC supply. These produce high starting torque. Most universal motors are designed to operate at higher speeds, exceeding 3500rpm.

Universal motors find their use in various home appliances like vacuum cleaners, drink and food mixers and domestic sewing machines. Higher-rated universal motors are used in portable drills, blenders, etc.

Variable frequency drive

It drives an AC electric motor by varying the frequency and voltage supplied to the electric motor. It allows speed changing of three-phase motors over a designated speed range while providing constant or variable torque as the application requires.

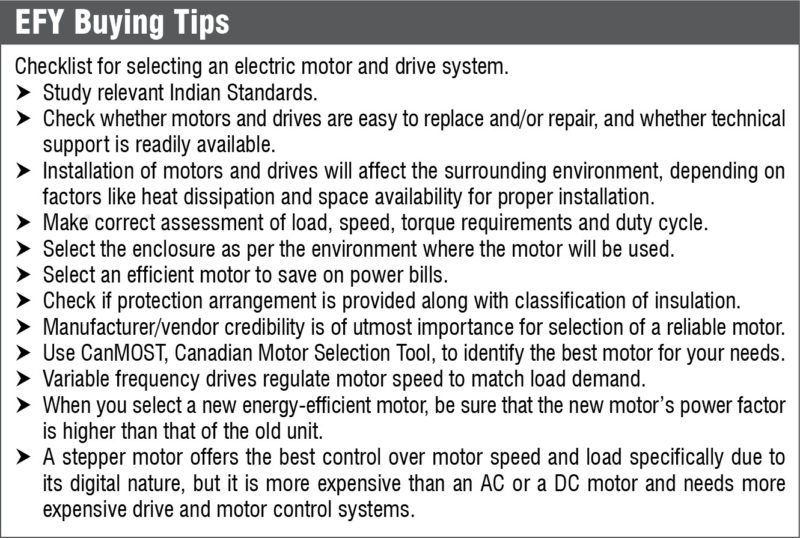

Selection of motor

There are two occasions when you need an induction motor. First is the replacement of existing motor and second is ab initio selection of a new application. Replacement of a motor, which has become unserviceable due to normal wear and tear, is simpler as specifications of the motor can be obtained from the plate affixed on the frame of the motor. Reasons for failure must be determined for correct selection. For example, if the motor is failing repeatedly, then obviously there is a mismatch between performance characteristics and application.

For a new application, selection can be done after evaluating horse power (HP) or kilowatt (kW) rating, speed in rpm, efficiency, duty cycle, motor frame, driving voltage and frequency, enclosures, frame size, insulation and altitude.

Horse power and speed rating. Torque and HP are two very important characteristics that determine the size of the motor for a particular application. HP and speed ratings have to be matched to load requirements. The HP ratings are generally divided into three categories: fractional motors (0.05HP to 1HP), integral HP motors (1HP to 400HP) and large motors (100HP to 50,000HP).

Rpm of the motor should also match load requirements. Rated speed is the speed at which the motor runs when fully loaded and is supplied with rated voltage. Common rpm ratings are 3600rpm (two-pole), 1800rpm (four-pole) and 1200rpm (six-pole).

Most motors are directly coupled to the driven equipment when speed of the motor and the driven equipment are the same. In other cases devices like gearbox, chains or belts are introduced between the motor and driven equipment.

Efficiency. Motor efficiency requires due attention when selecting a motor for a specific application. Motors running continuously should be as efficient as possible to reduce power consumption. Improvement of even one per cent in efficiency results in savings of enormous power over life span of the motor and thus the cost of power. Standards are defined in IS 12615:2011; these are IE2 – high, IE3 – premium and IE4 – super premium.

Duty cycle. Selecting a proper electric motor depends on load pattern, which can be steady or variable over a fixed time duration, following a repetitive cycle of variation or load with pulsating torque or shocks.

Duty cycle is a fixed repetitive load pattern over a given period of time, and is expressed as the ratio of on-time to cycle period. Frequent starts shorten the life because inrush current at start up heats the conductor rapidly. Duty cycle is also a factor in sizing electric motors.

Voltage and frequency. Location where the motor is used dictates voltage and frequency requirements. Supply voltage could be single- or three-phase. It is common to have three-phase motors built in dual voltage ratings of 230/460 volts, 50Hz.

Enclosures. A motor’s enclosure not only holds its components together, it also protects the internal components from moisture and contaminants. The degree of protection and motor’s cooling depends on enclosure type. There are two kinds of enclosures: open and closed.

Open-enclosure motors are designated as drip-proof. An open drip-proof motor allows free exchange of air from outside the motor to circulate around the winding, while being unaffected by drops of liquid or particles that strike or enter the enclosure at any angle from zero to 15 degrees downward from the vertical.

Enclosed category includes three types: totally-enclosed non-ventilated, totally-enclosed fan-cooled and explosion-proof. A good enclosure protects from dust, oil, water and high-pressure liquids so that the motor can be used indoors and outdoors. These are suitable for operation in harsh environments.

Frame size. International standards for frame size follow IEC classifications. Relevant Indian standards are IS1231 and IS2223. HP, rpm and enclosure dictate frame sizes. Frame size determines the distance between foot holes nearest to the shaft and opposite drive-end foot holes. This information is required for mounting of the motor.

Insulation. Heat is the biggest enemy of motor. Life of the motor greatly depends on the temperature rise of the windings. Main purpose of insulation is to protect the windings in the slots of the stator against heat.

According to IEEE regulation, classification of electric motors’ insulation is an indicator of maximum temperature that insulation can tolerate. These are designated by alphabets; for example, for class A insulation maximum temperature is 105°C, and for class S it is 240°C.

We can see insulation class on the motor’s plate. Selection of class of insulation is based on the type of load (pump, lift or conveyer belt), working area’s ambient temperature and cooling arrangement.

Altitude. This indicates the maximum height above sea level at which the motor will remain within its stated parameters.

Nidhi Kathuria is a senior application engineer at EFY Labs, New Delhi

Where can I find a BLDC geared motor having the specifications 48V, 600-750W, 20Ah, torque>30 Nm, 1500-2000rpm