If you are planning to make your own multi-rotor from scratch at home, note that choosing the right electronic speed control (ESC) for your radio-controlled electric aircraft (RC plane) is not an easy task. Although a number of interesting multi-rotor platforms, like monocopter, twincopter, tricopter, quadcopter, hexacopter and octocopter, are available now, building one for fun flying/hovering completely depends on your imagination, skill and, of course, judicious selection and use of system components.

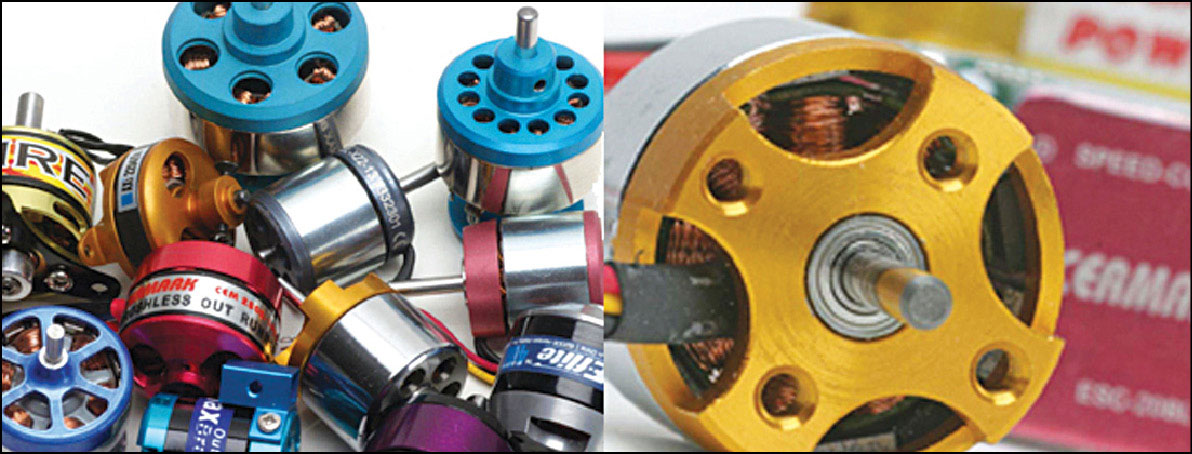

In any model aircraft, key components of the power system include an electric motor, electronic speed control and a battery pack. A perfectly-matched combination of the key components will bring out an efficient output from the power system. In fact, performance of the entire power system depends on the selection of the motor. Usually, brush-less motors (brush-less out-runner motors) are used in a power system.

Motor selection

There are a few vital considerations you should keep in mind when choosing the motor. The easiest choice is whether to use direct drive or a gear box, because if you are looking for high rpm (revolutions per minute), you will probably need a direct drive in-runner motor. For lower rpm, you can pick an out-runner in direct drive (or try an in-runner through a gearbox). In connection with this, always do your homework on other important things, like kV ratings (kV=rpm/V) of the motor, battery voltage and capacity of the battery pack, among others. Some important specifications that come with brush-less motors are kV, max. current (A), shaft diameter, thrust, suggested propeller, lithium polymer (LiPo) (3S-4S) and weight.

With a known kV rating, you can calculate the rpm of the motor using the formula rpm=kVxV, where V is battery voltage. The maximum current rating indication helps you pick the right ESC and battery pack. Similarly, the shaft diameter helps you select the right propeller. Thrust is the value of the force that the motor can produce with the suggested propeller. LiPo (3S-4S) indicates the motor’s ability to run on 3-series (3S=11.1V) and/or 4-series (4S=14.8V) LiPo battery packs.

Rough calculation. If you are making a quadcopter for lifting 1000gm of payload, 2000gm thrust is a common requirement*. Since a quadcopter has four motors, each motor should handle at least 500gm of thrust to function better.

(*The basic formula you should keep in mind is that, AUW (all up weight) of a multi-rotor should be half of the total thrust, that is, total thrust (minimum)=2x AUW.)

Electronic speed controls

For the ESC to work with your selected motor, it must be rated for voltage of your LiPo battery pack, and it must be able to handle the motor’s voltage and current requirements. In principle, it is always better to have an ESC with a rating slightly higher (1.5x maximum) than the peak current (at full throttle) requirement of the motor.

All ESCs have inherent voltage and current limitations. So, select an ESC that is designed to work with an equal or higher voltage. It is not recommended to connect a high-voltage battery to a low-voltage ESC, and a high-voltage ESC to a low-voltage battery. Likewise, it is very important to know the peak current rate of the motor at full throttle. Always prefer an ESC with a current rating that is higher than the actual demand.

ESC provides varying electric power from the battery pack, according to the input signal. Most ESCs also have a battery eliminated circuit, which is nothing but a 5V DC output that can power-up the electronics, including the receiver, servo motor and flight controller.

Another feature available in many ESCs is low-voltage cut-off (LVC) circuitry. This protects the LiPo battery pack from being discharged too much, to save it from being permanently damaged. We can fine-tune most ESCs with exotic throttle profiles (throttle range, battery mode, etc), with the help of computer based configuration programs.

Rough calculation. If the maximum current rating of the motor is 10A, then the capacity of the ESC should be 10×1.5=15A and I(ESC)= Imax (motor)x1.5)

The propeller size strongly influences the electric current flow through a system. A large propeller will draw higher current from the battery through the ESC and make the system run hot. Since every motor, ESC and battery operates at a specific maximum allowable current, exceeding the limits could soon burn-out the motor, ESC or battery pack.

Battery pack

Compared to NiMH and NiCd battery packs, LiPo battery packs are ideal for use with brush-less motors in radio-controlled airplanes and copters due to their small profile, low weight and high capacity. When looking for a battery pack, keep an eye on the maximum current rating of the motor(s) used, at first.

Some important specifications of a battery pack are mAh, C and 1S/2S/3S/4S.

mAh rating indicates the capacity of the battery pack (more mAh gives more flight time). C is the discharge rate, that is, an indicator of the maximum current (A) level at which a battery can be discharged at a particular time period. 1S/2S/3S/4S reveals the inside combination of the LiPo battery pack. 1S means one cell of 3.7V, while 4S means four cells of 3.7V (14.8V). Just multiply C rating with the battery pack’s capacity (mAh) to determine how many amperes can safely be pulled from the battery pack. For example, an 800mAh battery with 10C rating can continuously provide an output of 8A (0.8×10=8).

Quick tip. For a longer flight time, it is better to use a battery with higher mAh capacity at the same C rating, or a battery with higher C rating at the same mAh capacity. For example, an 800mAh 20C battery is better than 1500mAh 10C battery, because 800mAhx20C=16A and 1500mAhx10C=15A.

Flight controller (FC)

Literally, a flight controller overlooks the operation of the flying machine, including reading RC radio inputs, controlling motors and determining the orientation.

RC radios have multiple signal outputs, one for each channel/stick/switch/knob. Each radio output transmits a pulse (usually at 50Hz), with the width of the pulse determining where the stick is on the RC transmitter (for example, 1000µS for throttle 0).

As stated, motors are controlled with the ESC. It is always necessary to determine which orientation, or attitude, the flying machine is in for, for varying the motor speed along with the pilot’s commands. In practice, two sensors are commonly used for determining orientation—accelerometer and gyroscope. An accelerometer measures acceleration in each direction and a gyroscope measures the angular velocity.

DIYers, think first

Building your own ESC for brushed/brush-less motors is not a very difficult task if you have enough knowledge, skill and patience. There are a number of tried and tested designs that have been published for ESCs. However, reliability of a home-made ESC may raise an important safety issue because a DIY ESC is probably going to be heavier than an SMT based modern commercial ESC. Under certain circumstances, you can save money by building your own ESC, but most of the time there is not much cost advantage to it.

[stextbox id=”info” caption=”Important challenges in designing an ESC are:”]1. Accurate timing of the throttle control pulse

2. Accurate pulse width modulation (PWM) generation to ensure the motor speed is even, and the motor does not make unacceptable noise and harmful vibrations

3. Integration of optional features, like lost model alarm (LMA) and glitch counter

4. Maximising power efficiency[/stextbox]

[stextbox id=”warning” caption=”Warning!”]Model aircraft is not a toy. Please construct, test and use RC flying models at your own risk.[/stextbox]