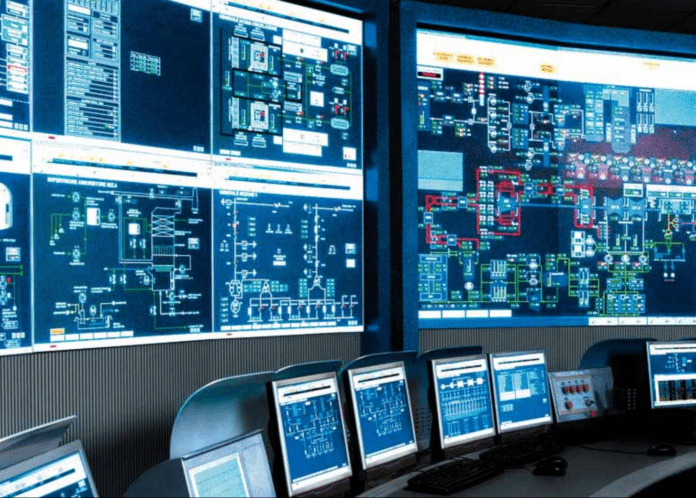

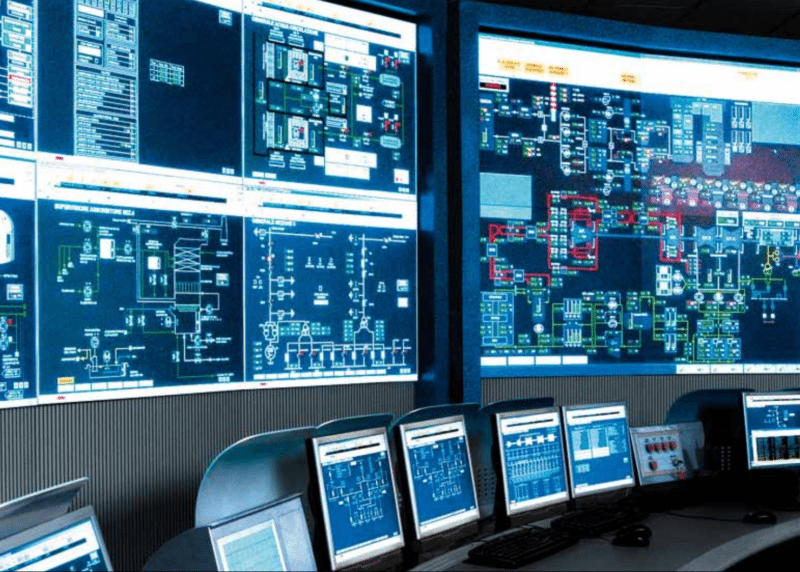

SCADA relates to software which is used to control hardware and acquire data from these devices. When we break it down to essentials, we have Supervisory control and data acquisition, which has been explained by Rajvir in the video below.

SCADA (supervisory control and data acquisition) is a category of software application program for process control, the gathering of data in real time from remote locations in order to control equipment and conditions. SCADA is used in power plants as well as in oil and gas refining, telecommunications, transportation, and water and waste control.

Such systems are used in monitoring and control of a manufacturing plant’s operating systems from a centralized location. It includes a mode for communication of information between the central host computer to the many scattered units (Programmable Logic Controllers). The systems may vary from a simple temperature reporting system in a building to complex monitoring systems for traffic lights. The major elements of the system are:

Master Station

It is a repository of real-time or near real-time reported data collected from the remote terminal units connected to the master system. Generally, it is a standard computer hardware equipment but there are few specialised available as well. The back end SCADA software must be able to repeatedly poll the RTUs for data values, should have software for their retrieval, storage and processing. The processing may include unit conversion, cataloguing into tables etc.

Human-Machine Interface

This is basically the command center that allows control of the devices. The values stored in the computers are accesses here in an understandable and comprehensible form by HMIs. These are helpful in providing diagnostics and management information with detailed schematics Humans work well with pictures, hence similar are the SCADA HMIs.

Remote Terminal Units (RTUs)

It connect to sensors in the process, converting sensor signals to digital data and sending digital data to the supervisory system.

Programmable Logic Controller (PLCs)

It is used as field devices because they are more economical, versatile, flexible, and configurable than special-purpose RTUs.

Communication infrastructure in SCADA

It provides connectivity to the supervisory system to the Remote Terminal Units.

Video Courtesy: Rajvir Singh

We start the video with an explanation of the SCADA architecture, and the different components involved in the design. Then he moves on to explain the various units in a SCADA design. He then goes on to explain the data flow in a data acquisition model. The components in the model are also explained very well. We also have some examples of SCADA implementation in food processing, chemical and water treatment plants.

Some SCADA software available here.