- ADLINK Technology’s smart camera supports the deployment of AI-based machine vision while giving IoT solution teams the tools to automate machine vision work

- It provides optimised ML models along with high AI computing power, maximising production efficiency in smart manufacturing

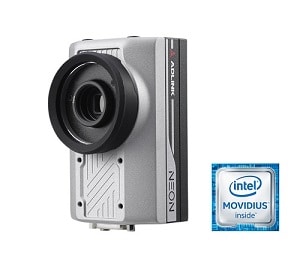

ADLINK Technology has launched a new NEON-1000-MDX Smart Camera series together with its Smart Pallet solution, combining the Intel Movidius Myriad X VPU, which supports inference models optimized by OpenVINOTM and ADLINK’s Edge vision software to add AI-based machine vision into existing environments easily and quickly.

ADLINK Technology has launched a new NEON-1000-MDX Smart Camera series together with its Smart Pallet solution, combining the Intel Movidius Myriad X VPU, which supports inference models optimized by OpenVINOTM and ADLINK’s Edge vision software to add AI-based machine vision into existing environments easily and quickly.

The all-in-one solution allows machine vision experts and developers to build, test and deploy machine learning (ML) models faster, while giving IoT solution teams and system integrators the tools to connect, stream and automate machine vision work.

“We’re all feeling the pressure of ramped up production during these unprecedented times. Machine vision AI is one of the quickest, easiest and most cost-effective ways to add automation into existing processes without disrupting current workflows,” said Kevin Hsu, Senior Product Manager of ADLINK’s IoT Solutions and Technology Business Unit. “Our Smart Pallet solution, for instance, has proven to deliver a 90% reduction in traditional barcode scanning time while also enabling customized, built-to-order pallets with no changes to the production line other than the smart camera’s installation. Using the highly integrated NEON-1000 effectively decreases the footprint, reliability and compatibility issue and also saves maintenance efforts for customers.”

Advanced AI computing

The Intel Movidius Myriad X VPU (vision processing unit) optimizes ML models and provides high AI computing power. By eliminating complex integration of sensor modules, cables and VPU modules, the NEON-1000-MDX Smart Camera simplifies the machine vision deployment process. With the pre-installed EVA (Edge Vision Analytics) SDK, users can deploy neural networks optimized by OpenVINO without extra coding or integration efforts using a wide range of ready to use plug-ins based on environment and system requirements.

The new all-in-one NEON-1000-MDX AI smart camera supports product classification and defect detection for maximising production efficiency in smart manufacturing. The ADLINK Edge Smart Pallet solution adds intelligence and automation to manual warehouse fulfillment operations such as receiving, bin picking, packing, shipping and worker safety. It provides an end-to-end integrated system for connecting new and existing equipment, capturing multiple image data streams and applying high performance processing power of the NEON-1000-MDX VPUs to enable machine learning and inferencing at the edge.

Varied connection and integration

With the ADLINK Edge software platform developers can connect and integrate with any existing cloud, machine learning platform, neural network, industrial camera, machine vision system, piece of machinery and more – regardless of vendor. ADLINK’s machine vision AI software can classify what it sees, become smarter over time and also create automation workflows.

“For instance, if a box contains the incorrect order on a conveyor system, it can send an alert to a conveyor’s sorter to divert the box to a re-check area,” said Steve Cammish, VP of ADLINK’s IoT Solutions and Technology. “We’re bringing software developers intuitive programming, automation and device management running on a powerful smart camera designed for AI workloads. The automation here is key- saving time, decreasing costs and reducing complexity.”