- Infineon Technologies latest product offering for electric vehicles provides optimal performance in a compact package

- The new module is an improved version of the company’s previous HybridPACK1 series

An increase in vehicle electrification has put the design of cost-effective traction inverters into focus. In this context, selecting the right power module plays an important role. System designers are currently looking for the best-sized module with the optimal silicon area for the required performance.

An increase in vehicle electrification has put the design of cost-effective traction inverters into focus. In this context, selecting the right power module plays an important role. System designers are currently looking for the best-sized module with the optimal silicon area for the required performance.

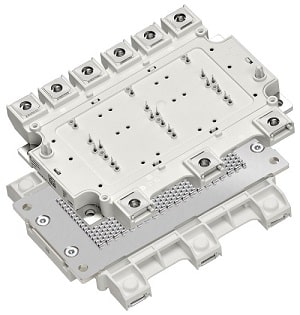

Infineon Technologies has now introduced a new IGBT power module called the HybridPACK™ DC6i that can fulfil the needs of electric vehicle traction inverters in the 80 kW to 100 kW power class. This six-pack module offers excellent performance to hybrid and small battery electric vehicles. By combining Infineon’s EDT2 IGBTs with compact package technologies, good thermal management at reduced material cost and easy installation can be attained.

The DC6i has been designed with an efficient and automized high-volume production in mind: Press-Fit pins and additional guiding elements enable gate driver board mounting in a few seconds compared to traditional selective soldering in more than one minute. A direct-cooling wave baseplate provides an excellent and cost-effective heat dissipation with a thermal resistance from the IGBT chip junction to the fluid of 0.17 K/W.

HybridPACK comparisons

Within the company’s power portfolio, the HybridPACK DC6i is positioned between the HybridPACK1 family and the more powerful HybridPACK Drive family.

- HybridPACK DC6i has the same compact footprint (7.2 cm x 14 cm) as the HybridPACK1 – 25 per cent smaller than the HybridPACK Drive – but the available output power is more than 50 per cent higher.

- While the HybridPACK1 uses Infineon’s IGBT3 technology, the HybridPACK DC6i is equipped with the latest EDT2 IGBTs.

- HybridPACK DC6i has six screw connectors to the DC-link capacitor compared to two in the HybridPACK1 family. This enables a low-inductive design with a stray inductance of 15 nH.

EDT2 technology

It is an automotive micro-pattern trench field-stop cell design optimized for electric drivetrain applications. It offers a blocking voltage of 750 V, a short-term extended operating temperature of 175 degrees Celsius and high short-circuit ruggedness. The design tradeoff between switching and conduction losses is optimized for a real-world driving cycle with excellent light load power losses, leading to efficiency improvement of 20 per cent compared to Infineon’s previous IGBT3 generation.

The new HybridPACK DC6i is fully qualified according to the AQG324 norm for automotive power modules. The module is in production and will be available at distributors in September 2020.