Did you know that it is possible to bulk print flexible electronic circuits using a standard inkjet printer?

By Anagha P

Flexible electronics is becoming very popular now, especially in medical, entertainment and wearable electronics. It calls for electronics printing methods that are fast, cheap and easy, and can produce circuits in bulk.

The issue with 3D electronics printers

As explained in the previous article, we expect 3D printers that can print electronics to be in the market by the end of 2015. But, the limitation of these printers is that they can create only rigid electronics. Another issue is that the conductive inks used in the existing methods are not very conductive. They offer mediocre conductivity and are suited only for simple, low power applications.

This creates the need for a better technology that can also print electronics circuitry in flexible surfaces, like say plastic sheets or even clothing materials.

The solution – inkjet printing

By using inkjet printing to produce electronic circuits, we can print flexible and stretchable conductors onto anything, including elastic materials and fabrics. Here we look at how two teams are using this technology…

The Purdue method

The folks at Purdue University have come up with the concept of using normal inkjet printers for printing flexible and stretchable electronics in mass quantities. A research paper on the method titled Mechanically Sintered Gallium–Indium Nanoparticles has been published by Rebecca Kramer et al in the Advanced Materials journal dated April 17, 2015.

(Image courtesy: Purdue University)

The operation: In its native form, liquid metal cannot be used for inkjet printing. To overcome this, the team uses mechanically-sintered gallium-indium nanoparticles, where liquid metal is turned into nanoparticles by immersing the alloy into a solvent such as ethanol and then subjecting the mixture to ultrasound to disperse the liquid metal in it. This method makes the liquid metal small enough to pass through an inkjet nozzle. Once the printing is done, the solvent evaporates and leaves behind nanoparticles and an oxidised gallium (Ga2O3) coating used to keep the liquid metal electrically inert during the process. This thin skin can be easily removed by stamping or dragging something across the surface, leaving a conducting wire on the material on which the design is printed. This also makes it possible to activate only selected portions, and even modify or upgrade it later depending on the particular design.

No heating required: Unlike other graphene-based printing techniques, the Purdue method does not require the printed material to be heated to very high temperatures to make it conductive. This simplicity makes the method more accessible to circuit designers.

Stretchable: Since they are made from liquid metal and can be printed on any material including plastic sheets, papers or even fabrics, these circuits can be stretched, folded and squeezed without breaking. This can be utilised for creating wearable devices that do not restrict motion and soft machines (like robots) that can squeeze through small spaces.

The Cartesian method

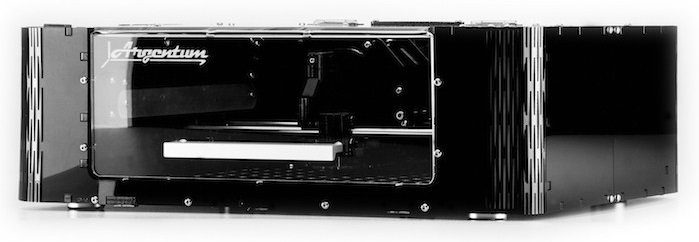

Australian start-up Cartesian Co. started a Kickstarter campaign in November 2013 for developing Argentum (previously EX1), which is supposedly the world’s first desktop electronics printer. The project got funded and they started shipping their first batch in August 2014. Similar to the previous method, Argentum lets you print both flexible and rigid electronic circuits on any material of your choice (polyimide, linen paper, fibre glass, synthetic paper, fabric etc), and it is as easy as printing a photo.

The method: Argentum comes with two inkjet cartridges similar to the ones in a desktop printer, and each cartridge is filled with a different chemical. Firstly it prints in one chemical, followed by the other chemical on top of the existing one. When these two chemicals mix, a reaction occurs and produces silver nanoparticles, leaving a silver image on the substrate.

Resolution and speed: The device can natively print images at 300 dots-per-inch (DPI), which can be enhanced to 600DPI using the accompanying software. The circuit can be created using any electronics circuit design tool or even Microsoft Paint, and can be easily exported to the printer software to print the circuit on the selected substrate. The printed circuit board (PCB) does not have to be etched either. This reduces the overall time to design, create and test a circuit.

Small form factor, big prints areas: The size of Argentum is about 43x32x17 centimetres (cm) and weighs around 6 kilograms, which is close to a normal desktop inkjet printer. The user can print circuits with a print area of 17.5x8cm, well above the size of what one can design in the free version of Eagle software.

Soldering: Circuits printed using Argentum can be reflow soldered with the conventional hot plate, reflow oven and hot air gun, using the leaded solder paste. It can also be hand soldered, though it needs to be done quickly and adeptly to avoid damaging the silver traces.

Commercialisation on demand

According to a report by IDTechX titled Printed, Organic & Flexible Electronics Forecasts, Players & Opportunities 2015-2025, the market for printed, flexible and organic electronics is set to increase from US$ 29.80 billion in 2015 to US$ 73.69 billion by 2025. Currently we are in the early days of electronics printing. But, with this increased market pull, we can be optimistic about more researchers and companies coming up with methods to print electronics circuits in mass.

The author is a dancer, karaoke aficionado, and a technical correspondent at EFY. Find her on Twitter @AnuBomb.