The term instrumentation amplifier is often misused, referring to the application rather than the architecture of the device. Historically, any amplifier that was considered precision (i.e., implemented some sort of input offset correction) was thought to be an “instrumentation amplifier,” since it was designed for use in measurement systems. Instrumentation amplifiers, or INAs, are related to operational amplifiers (op amps), in that they are based on the same basic building blocks. But an INA is a specialized device, designed for a specific function, as opposed to a fundamental building block. In this regard, instrumentation amplifiers are not op amps, in that they are designed to function differently.

Perhaps the most notable difference between an INA and an op amp, in terms of usage is the lack of a feedback loop. Op amps can be configured to perform a wide variety of functions, including inverting gain, non-inverting gain, voltage follower, integrator, low-pass filter, high-pass filter and many more. In all cases, the user is providing a feedback loop from the output of the op amp to the input, and that feedback loop determines the function of the amplifier circuit. This flexibility is why op amps are so prolific in a wide variety of applications. An INA, on the other hand, has this feedback internally, so there isn’t an external feedback to the input pins. For an INA, the configuration is limited to one or two external resistors, or perhaps a programmable register, to set the gain of the amplifier.

INAs are specifically designed and used for their differential-gain and common-mode-rejection capabilities. The instrumentation amplifier will amplify the difference between the inverting and non-inverting inputs while rejecting any signal that is common to both inputs, resulting in no common-mode component being present at the output of the INA. An op amp that is configured for gain (either inverting or non-inverting) will amplify the input signal by the set closed-loop gain, but the common-mode signal will remain at the output. The difference in gain between the signal of interest and the common-mode signal results in a reduction of common mode (as a percentage of the differential signal), but the common mode is still present at the output of the op amp, which limits the dynamic range of the output.

As mentioned, INAs are used to extract a small signal in the presence of a large common mode, but this common-mode component can take many forms. When using a sensor in a Wheatstone bridge configuration (which we will explore later), there is a large DC voltage that is common to both inputs. However, interference signals can take many forms; one common source is 50 or 60 Hz interference from the power lines, not to mention the harmonics. This time-varying error source often fluctuates greatly across frequency as well, making it extremely difficult to compensate for at the output of the instrumentation amplifier. These variances make specifying common-mode rejection, not only at DC but across a range of frequencies, important.

Difference Amp

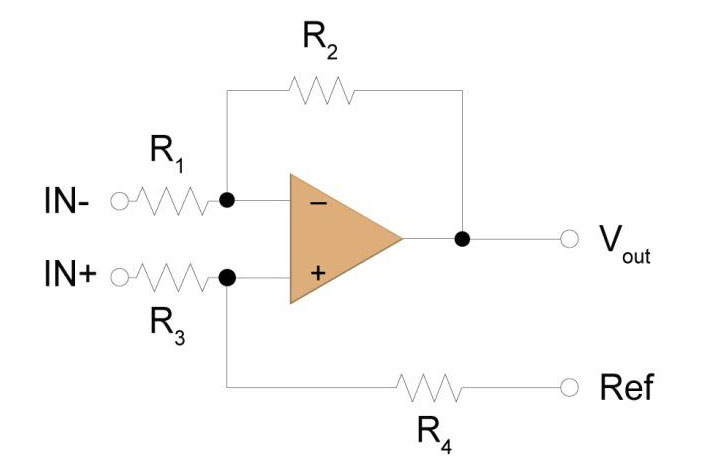

The first question one may have is, “Can’t I build an instrumentation amplifier out of simple op amps?” The short answer is yes, you can. But there are always trade-offs! One may first think of a simple difference amplifier circuit (Figure 1), sometimes called a subtractor.

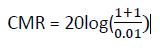

This is a very simple circuit that provides for differential gain and has some common-mode rejection, which is exactly what an INA is intended to do. Earlier, I mentioned trade-offs, and this circuit has a couple. First of all, let’s look at the input impedance. It is relatively low, as determined by the values of the resistors, which may be on the order of 100 kΩ. Secondly, the input impedances aren’t matched, meaning a different current will flow through each leg, causing the common-mode rejection to suffer. The other shortcoming of this simple circuit is the need for resistor matching. The common-mode rejection of this circuit is predominately determined by the level of matching within the resistor pairs, not the op amp itself. Any mismatch in these resistor pairs will reduce the common-mode rejection. The common-mode rejection of this difference amplifier can be calculated as:

Where: Rt = total mismatch of the resistor pairs in fractional form

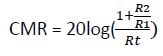

For example, assume R1 = R2 = R3 = R4 (providing unity gain), and the resistor mismatch is 1%. Using the above equation:

CMR = 46 dB

As this example shows, the performance one can achieve with this simple circuit is extremely limited. Even when matching resistors by hand, it will be difficult to achieve a common-mode rejection any greater than 66 dB. In addition, this does not take into account fluctuations due to temperature, as any difference in temperature coefficients among the resistors will further increase the mismatch and result in worse common-mode rejection. Taking all of these factors and limitations into account, a monolithic difference amplifier is usually the best solution for relatively high-performance applications.

The difference-amplifier circuit discussed previously is technically not an instrumentation amplifier, but is useful for certain applications requiring high speed and/or high common-mode voltage levels. For precision applications, an actual instrumentation amplifier is often the best choice. There are two common circuits utilized to create an instrumentation amplifier, one based on two amplifiers and one based on three amplifiers. Both will be discussed in detail. Note that these basic circuits can be constructed using standard op amps, but are also the underlying circuit concepts used in many of the monolithic instrumentation amplifiers offered today.

Two Op Amp INA

Figure 2 illustrates the popular instrumentation-amplifier circuit based on two amplifiers. In this circuit, the overall gain is set via one resistor, noted below as “RG”, such that:

![]()

One of the limitations of this circuit architecture is that it does not support unity gain. Although most instrumentation amplifiers are used to provide gain (and hence unity gain is not critical), some applications specifically use an instrumentation amplifier strictly for common-mode rejection. So, it is reasonable to assume that an INA may be used in a unity-gain configuration for some applications. Another limitation of the two op amp INA is that the common-mode range of the input is limited, especially at lower gains and when used with single-supply op amps. Keep in mind that the amplifier on the left-hand side of Figure 2 must amplify the input signal at the non-inverting node by 1+. So, if the common mode of the input signal is too high, the amplifier will saturate (run out of headroom on the output). At higher gains, there is more amplifier headroom and hence the circuit can support a wider input signal common-mode range, all else being equal.

One of the limitations of the difference-amplifier circuit discussed previously was the low input impedance. As can be seen in Figure 2, the two op amp INA circuit does not have this issue, since the two differential input signals feed directly into the input pins of the amplifiers, which generally have impedances in the millions of ohms. However, due to the difference in the input signal paths, there is a delay difference between the differential input signals, which results in poor common-mode rejection across frequency—a critical specification for instrumentation amplifiers. Similar to the difference-amplifier circuit, the common-mode rejection at DC is once again limited by the matching of the resistor ratios.

A monolithic INA that is based on this two op amp architecture will inherently have better resistor matching and temperature tracking, relative to a discrete solution, as silicon-based resistors can be trimmed to provide matching on the order of 0.01%. Still, the two op amp INA architecture has some definite limitations that cannot be overcome without changing the architecture of the circuit.

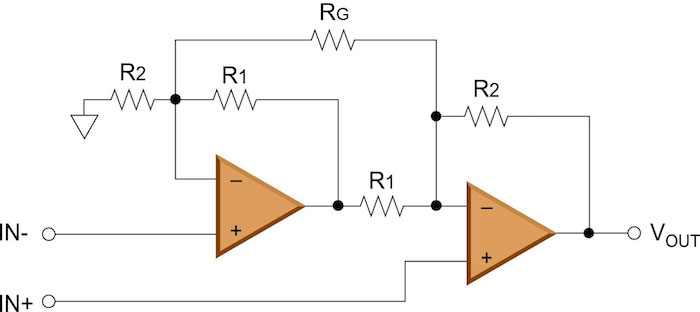

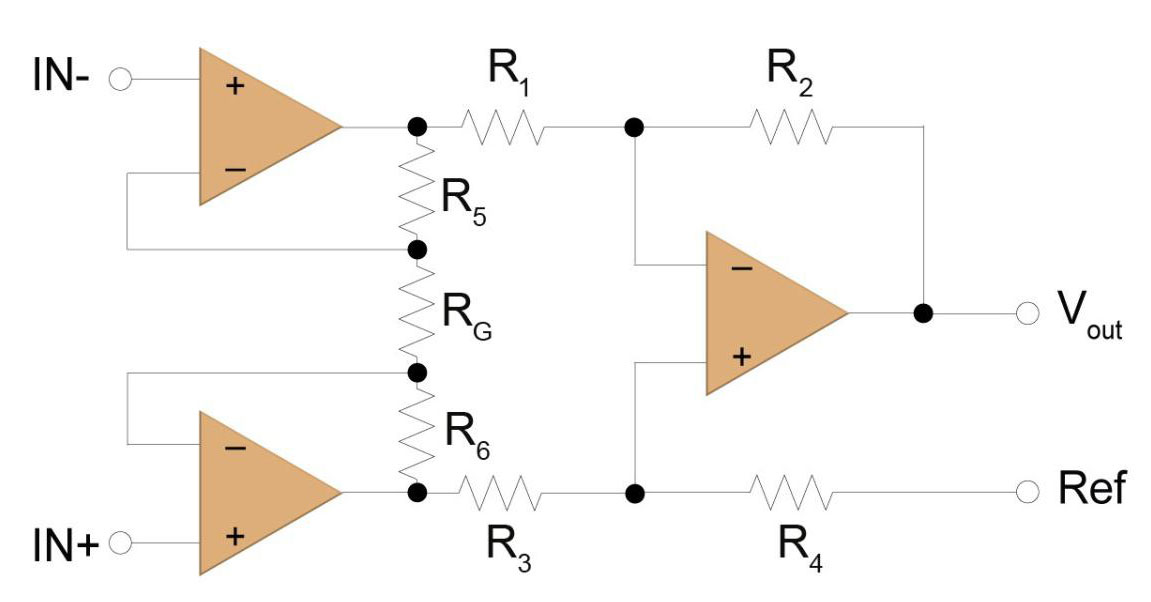

Three Op Amp INA

The second common INA circuit is based on three operational amplifiers, as shown in Figure 3. One may notice that the back half of this circuitry is identical to the difference amplifier that was previously discussed. The addition of two operational-amplifier buffers on the front end of the circuit provides a high, well-matched impedance source. This alleviates one of the main concerns with the simple differential circuit. The differential amplifier at the end provides the rejection of the common-mode component.

In this configuration, the gain of the circuit is set via the value of the resistor labeled RG. Looking at the input stage, consisting of the two operational amplifiers, any common-mode signal is only amplified by unity gain, regardless of the differential gain (set by RG) in the first two amplifiers. Hence, this circuitry can accommodate a wide common-mode range (limited by the headroom of the first two amplifiers), regardless of the gain. This is an advantage over the two op amp INA previously discussed. The difference amplifier will then remove any common-mode components. Similar to the previous architectures that have been discussed, the common-mode-rejection performance depends on the resistor ratio matching, as shown below:

![]()

Where: Rt = total mismatch of the resistor pairs

Due to the fact that the common-mode component always sees unity gain, the common-mode rejection of the three op amp instrumentation amplifier will increase proportionally with the amount of differential gain.

Several monolithic instrumentation amplifiers are based on this circuit concept. A monolithic solution offers very well matched amplifiers, and the ability to use trimmed resistors results in good common-mode rejection and gain accuracy. In more recent times, monolithic instrumentation amplifiers have made additional improvements to this basic architecture. Current-mode topologies, for example, eliminate the need for precision resistor matching in order to achieve high common-mode rejection. In any case, a discrete solution, using operational amplifiers and discrete components, will typically be more costly and result in degraded performance.

INA and Op Amp Specifications

As previously mentioned, operational amplifiers and instrumentation amplifiers are related, and as we have illustrated, op amps can be used to construct INAs. Due to this similarity, there are some specifications that are common to both operational and instrumentation amplifiers. However, there are also specifications that are unique to INAs, due to the specific functionality of such a device. Two important specifications for measurement applications that are common between op amps and INAs are input bias current and input offset voltage/offset voltage drift.

Input bias current is the amount of current flow into the inputs of the amplifier that is required to bias the input transistors. The magnitude of this current can vary from µA down to pA, and is strongly dependent upon the architecture of the amplifier-input circuitry. This parameter becomes extremely important when connecting a high-impedance sensor to the input of an amplifier. As the bias current flows through this high impedance, a voltage drop occurs across the impedance, resulting in a voltage error. Whether the circuit contains an operational amplifier or an instrumentation amplifier, bias current can play a critical role in the overall error budget of the circuitry.

Another important amplifier specification common to both operational and instrumentation amplifiers is input offset voltage. As the name implies, this specification is the amplifier’s voltage difference between the inverting and non-inverting inputs. This voltage offset is dependent on the topology of the amplifier, and can range from microvolts to millivolts in magnitude. Like all electrical components, amplifiers will change behavior over temperature. This is certainly true of the amplifier’s voltage offset. The voltage offset is a source of error, and, as the offset drifts over temperature, this error becomes correlated to the temperature. Even a high-precision amplifier will be susceptible to temperature drift. This error source can be minimized by selecting a low-drift amplifier—such as an amplifier with a zero-drift topology—or by implementing periodic system calibrations to calibrate out the offset and drift.

Due to the specialized nature of instrumentation amplifiers, there are additional specifications that are not typically found in standard operational-amplifier datasheets, including gain error and a non-linearity specification. Gain error is typically specified as a maximum percentage, and represents the maximum deviation from the ideal gain equation for that particular amplifier. Variations in resistor values and temperature gradients among the resistor networks can all contribute to gain error. The non-linearity specification also describes the gain characteristic of the amplifier. This specification defines the maximum variation from an ideal straight-line transfer function, when comparing output versus input. For example, if an instrumentation amplifier is configured for a gain of ten, then a DC input of 100 mV should produce 1V at the output. If the input is taken up to 500 mV, then the output should be at 5V. These two points represent the straight-line input to output transfer function for the amplifier. Any deviation from this straight line is highlighted by the non-linearity specification.

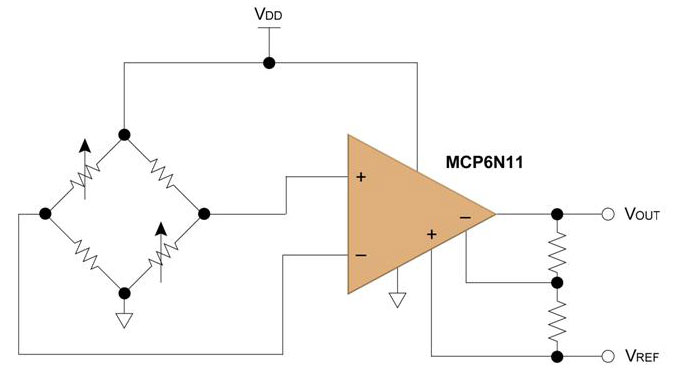

Application Example: Wheatstone Bridge

As noted previously, instrumentation amplifiers are designed to provide differential gain and good rejection of common-mode signals. These characteristics make INAs very popular for sensors (such as strain gauges) arranged in the classic Wheatstone-bridge configuration. A Wheatstone bridge for a strain-gauge application consists of four elements arranged in a diamond pattern, with each side consisting of a resistive element (either a strain gauge or a fixed resistor). An excitation voltage is then applied to the bridge, and the output voltage across the middle of the bridge is measured. A quarter bridge consists of only one variable-resistor element—the strain gauge. A half bridge has two variable-resistor elements, and a full bridge has all four elements as variable-resistor elements—in this case, strain gauges. The advantage of having more strain gauges is an increase in sensitivity. All else being equal, a half-bridge configuration will have twice the sensitivity as a quarter bridge, while the full bridge will have four times the sensitivity as the quarter bridge.

In this example, the Wheatstone bridge is excited by a DC source. Assuming VDD is set to 5V, this creates a DC common mode of approximately 2.5V at the center taps of the bridge. A force applied to the strain gauges will cause a change in their respective resistances, creating a small voltage differential across the center taps. This voltage change is very small relative to the common-mode voltage—typically on the order of 10 millivolts—hence the need for amplification of this small differential voltage. An instrumentation amplifier is ideally suited for this task, not only providing the needed amplification, but also rejecting the relatively high common-mode signal (and any additional noise that is common to both input signals). Keep in mind that an operational amplifier configured as a simple gain stage will still pass the common-mode signal (at unity gain) to the output, reducing the dynamic range of the output signal.

Conclusion

In the world of system design, the term “instrumentation” can take several meanings. Historically, the term has been used to describe the application, usually a physical phenomenon that is being measured or recorded. Hence, any operational amplifiers that were designed for use in such applications became known as “instrumentation amplifiers”. Adding to the confusion is the fact that actual instrumentation amplifiers can be constructed using operational amplifiers.

In reality, operational amplifiers and instrumentation amplifiers are very different devices, designed to do different functions. Instrumentation amplifiers can be thought of as a specialized amplifier, used specifically for its differential-gain and common-mode-rejection capabilities. As we have seen throughout this article, circuits implementing traditional operational amplifiers can be created to perform these same functions. However, in most cases, a monolithic instrumentation amplifier will provide a substantially higher level of performance and reliability.