Energy crisis and environmental pollution have triggered the development of clean and renewable energy storage systems. Supercapacitors also called ultra-capacitors or Electrical Double Layer Capacitor (EDLC), provide very high capacitance in a small package. It stores electric energy in the form of the electric field between two conducting plates and can complete hundreds of thousands more charge-discharge cycle than batteries because they do not experience wear and tear associated with the chemical reaction. Due to this reason and its increased use in electric drives, UPS, active filters, traction and automotive drives has grabbed the attention to know the peculiarity of it.

Structure of Supercapacitor

Before we move on to the working of Supercapacitors, let us first understand the structure of a supercapacitor.

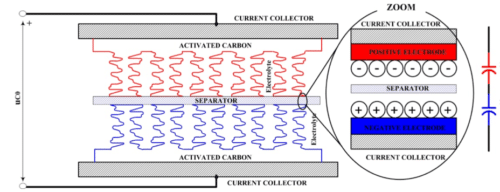

Figure 1. Supercapacitor cross-section

It does not consist of a dielectric material like ceramic capacitors or electrolyte capacitors do have. As shown in figure 1, supercapacitors consist of two porous electrodes, electrolyte, a separator and current collectors. Let us look at each of these.

Current collector:

Current collectors are made up of metal foil generally of aluminum as it is cheaper than titanium, platinum etc. They are coated with the electrode material.

Electrodes:

The capacitance value is proportional to the surface area of the electrode. Generally, as an electrode material, highly porous powdered coated active carbon material or carbon nanotubes are used. The porous nature of the material allows many more charge carriers (ions or radicals from electrolyte) to be stored in given volume. This increases the capacitance value of supercapacitors. The electrodes are coated on a current collector and immersed in an electrolyte.

Electrolyte:

The electrolyte is the key factor in determining the internal resistance (ESR). The electrolyte solution shall be either aqueous or non-aqueous in nature. The non-aqueous electrolytes are mostly preferred as they provide high terminal voltage V. Non-aqueous solution consists of conductive salts dissolved in solvents. Acetonitrile or propylene carbonate as solvents preferred mostly. Tetraalkylammonium or lithium ions can be used as solutes.

Separator:

The separator is between electrodes and it is made up of material that is transparent to ions but is an insulator for direct contact between porous electrodes to avoid short circuit.

The structure of supercapacitor is unique and hence it differs from conventional batteries and capacitors. Use of activated carbon increases surface area and hence increase in capacitance value. Electrolyte with low internal resistance increases power density. These both together brings ability in supercapacitors to store and release energy rapidly. The power [W] of supercapacitor is given by,

P= V2/4R

where V [Volts] is the operating voltage and R [Ω] is internal resistance.

Energy storage in Supercapacitors

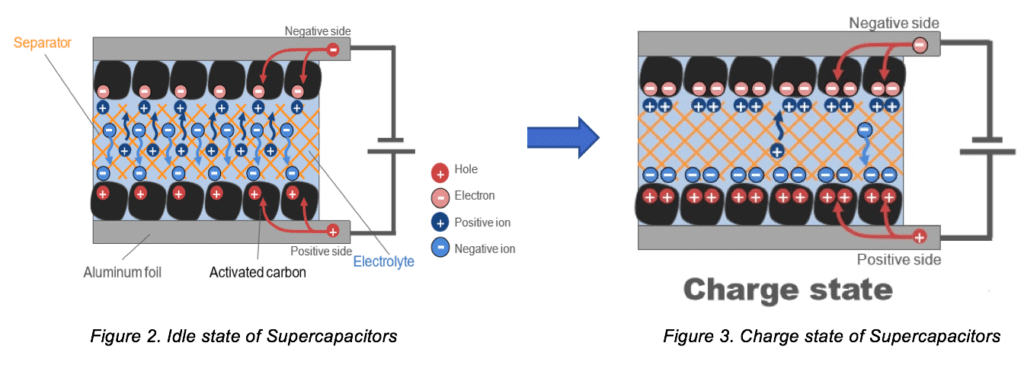

When the voltage is applied, charging starts, means the electric field starts developing. Let us understand the process of charging referring figure 2 and 3.

The process of charging is as follows:

On applying voltage, each collector attracts ions of opposite charge.

Ions from electrolyte get collected on the surface of the two current collectors.

A charge is built on each current collector.

As we can see in figure 3, two separate layers of charge have been formed, hence supercapacitor is also called as an Electrical Double Layer Capacitor (EDLC).

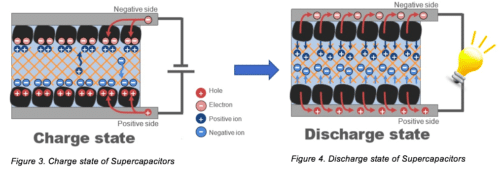

Now we would understand the process of discharging taking reference of figure 3 again and figure 4.

The process of discharge is as follows:

- Ions are no longer strongly attracted to current collectors.

- Ions get distributed through the electrolyte.

- Charge on both current collector decreases.

Advantages of Supercapacitors

- Use of activated carbon material increases capacitance value, so supercapacitors have high energy storage capacity as compared to electrolyte capacitors and batteries.

- Long shelf life as compared to batteries. In batteries, the energy is stored and released via a chemical reaction inside electrode material which causes degradation.

- Supercapacitors can recharge in short time, and supply high and frequent power demand peaks.

- Supercapacitors have high power density and can provide large power burst for short duration.

Application of Supercapacitors

Due to unique storage capability of supercapacitors, it has been widely used in various applications like electric drives, UPS, traction, electric vehicles, SSD’s, LED flashlights etc. Let us discuss few of them.

Hybrid Buses

Transportation is the biggest market for supercapacitors. In India, at the end of the month, October 2017 BEST (Brihan Electric Supply and Transport) has introduced emission-free electric buses. We have earlier in this document discussed that Supercapacitors gets charged quickly. Batteries take time to get charged. During braking, back emf is produced by the motors. This back emf as regenerative energy is used to charge the supercapacitors. Supercapacitors as the combined solution with battery increase the life of the battery, reduce the size of the battery.

Figure 5. Hybrid Bus in Mumbai, India

In Shanghai, buses are running on supercapacitors as a lone power supply (it is recharged every third stop in 1-2 min with the help of regenerative energy being produced by braking). China has demonstrated to the world that this technology can be implemented on large scale. However, the technology using supercapacitor plus the battery is more advantageous in terms of overall running performance of buses.

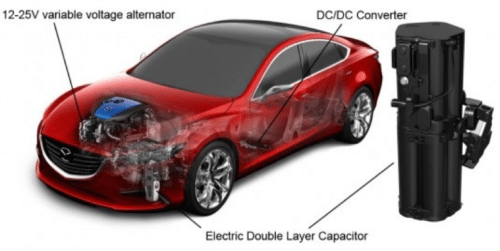

Automotive

While braking, the back emf produced by the motors is used to charge supercapacitor in an electric vehicle. Supercapacitors can charge in just a few seconds. This stored energy is used to start the engine, to power electrical system of the vehicle, and also to charge a battery used in vehicles. In India, Tata Motors has recently rolled out the first batch of Tigor EV manufactured for government-run entity EESL (Energy Efficiency Services).

Figure 6. Electric Vehicles using Supercapacitors

Traction

The traction vehicle must undergo three different phases, acceleration phase, cruising phase (running at normal speed), and deceleration phase. During these phases, the power can be highly negative as well as positive. This variation of power creates serious issues such as supply voltage fluctuation, losses in main power supply etc.

The solution of above problem is to integrate supercapacitors as a short-term storage device with an interface dc-dc converter.

Electronic and low power applications

Supercapacitors are used in memory devices in laptops, mobile phones, radio tuners etc.

They are used where momentary power burst is required like LED flash units.

Renewable Energy

Nowadays, advance variable speed turbines are used with three blades. The blades angle is flexible and can be adjusted depending on turbine operating point and wind speed. In case of turbine or power converter failure, the blades must be driven to 90° position quickly to prevent the blades from mechanical damage. Supercapacitors are used in wind energy to provide power for blade pitch control.

References

- Petar J. Grbovic, “Ultra-capacitors in Power conversion systems: applications, analysis and design from theory to practice”, 1st edition, Wiley IEEE press, 2014.

- R. C. Ambare, Rajaram S. Mane, B. J. Lokhande, “A review on electrochemical supercapacitors of composite-metal-oxide nanostructures”, International Journals of Advanced research, ISSN: 2320-5407, 2016.

- R. P. Deshpande, “Nanoscience in Energy Sector”, YMCAUST International Journal of Research, ISSN: 2319-9377, 2013.

- Petar J. Grbović, Philippe Delarue and Philippe Le Moigne, “Interface Converters for Ultra-capacitor Applications in Power Conversion Systems”, 15th International Power Electronics and Motion Control Conference, EPE-PEMC 2012 ECCE Europe, Novi Sad, Serbia.

- Petar J. Grbović, Philippe Delarue and Philippe Le Moigne, “Modelling and control of Ultra-capacitor based Energy storage and Power conversion system” IEEE Trans Industrial electronics, 2014.

- Niraj Mahulkar, Prof Dr. P. B. Karandikar, “Comparison of different types of carbon materials as electrodes of Supercapacitors”, International Journal of Innovative Research in Science, Engineering and Technology, vol 3 issue 6, ISSN: 2319-8753, 2014.

- M Jayalakshmi, K Balasubramania, “Simple Capacitors to Supercapacitors – An Overview”, International Journal of Electrochemical Science, ISSN: 1196 – 1217, 2008.

- Maxwell, “Top 5 markets for Ultracapacitor technology”, 2015.

- Murata, “Supercapacitors Basics (part 1): What are supercapacitors?”, 2015.

- Murata, “Supercapacitors Basics (part 2): Uses and effects”, 2015.

whether structural supercapacitor completely replace battery in electrical vehicle