From the integration of cutting-edge AI and IoT to innovations in miniaturisation and vision systems, delve into the future where these machines streamline production processes and redefine the efficiency and adaptability of assembly lines across industries.

In the fast-paced world of manufacturing, where efficiency and precision are paramount, pick-and-place (PnP) machines have emerged as the unsung heroes of the assembly line. These sophisticated devices are instrumental in various industries, from electronics to food packaging, embodying the spirit of innovation that drives modern production processes. But what makes these machines indispensable, and how are they evolving to meet the demands of an increasingly complex manufacturing landscape?

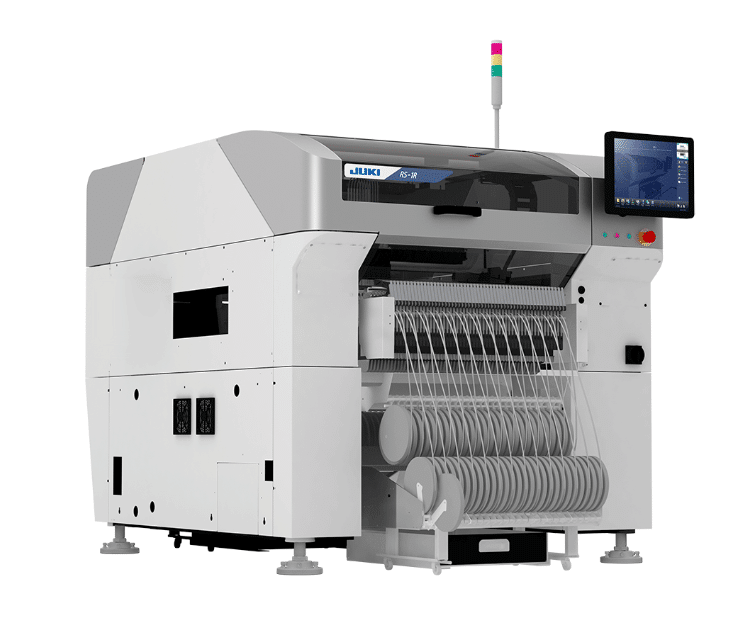

At the core of this evolution lies the challenge of miniaturisation and the ubiquitous integration of electronics. As mentioned by Shailendra Mathur, Business Head and Product Manager (Alternative Energy Solutions), MaximSMT, as components become smaller and production demands soar, PnP machines are pushed to their limits, striving for more incredible speed, accuracy, and efficiency. But have you ever wondered how these machines maintain such high precision in placing tiny components onto PCBs or packing products with unerring accuracy?

The quest for optimal efficiency

A crucial aspect of enhancing production efficiency is reducing setup and changeover times. These often-overlooked periods can significantly impact a production line’s overall efficiency. Every minute saved in these processes translates into valuable production time. But how are manufacturers minimising these ‘hidden’ downtimes?

During a conversation with EFY’s Akansha Sondhi Gaur, Shreyansh Gupta, Manager and Sales Marketing, DJK emphasised that the verification process ensures that every component is correctly placed, aiming for zero wrong production. By integrating advanced sensors and vision systems, machines can automatically detect and correct errors, significantly reducing setup times. Even a tiny rejection rate can have substantial financial implications in a high-volume production.

How is the integration of IoT transforming the way machines operate and communicate in the manufacturing ecosystem? While hardware developments have their limitations, software advancements are revolutionising PnP technology. Integrating artificial intelligence (AI) and machine learning (ML) enables machines to learn from patterns, predict maintenance needs, and optimise production processes. This shift reduces downtime and enhances overall equipment efficiency (OEE).

But what does the future hold for AI and ML in manufacturing? The move towards ‘black room technology’—fully automated, robot-assisted production lines—minimises human error and increases efficiency. The industry is shifting towards more efficient, error-free manufacturing by relying on robotics. The integration of Industry 4.0 standards is creating an interconnected ecosystem where machines communicate and make data-driven decisions. How are these advancements shaping the future of manufacturing?

Critical advancements