The deployment of drones/unmanned aerial vehicles (UAVs) has made the job easier, faster, and safer for surveyors. Some drones are specifically designed for data acquisition and surveying professionals, and are equipped with a high-resolution digital camera.

In the era of the Internet of Things (IoT), one of the prevalent concerns is the deployment of unmanned aerial vehicles (UAVs) to automate different commercial applications, ranging from simple deliveries to more sophisticated aerial taxis. This creates a requirement for different measurements conducted with drones, which serve as the basis for further evaluation of potential UAV applications.

Surveying with drones makes the job easier, faster, and safer for surveyors. It captures and measures image data with a substantially increased spatial and temporal resolution as compared to many classical methods. Some drones are specifically designed for data acquisition and surveying professionals, who need accuracy and efficiency. These drones are equipped with a high-resolution digital camera that has been geometrically calibrated to perform measurements.

Drone mapping is the process of surveying an area of land with a UAV, taking hundreds of pictures as it moves. Then with the help of computer software, it stitches and layers the images to analyse different results. Some of the most significant applications of drone mapping include construction sites, oil and gas, infrastructure, archaeological sites, mining, land surveying, property surveying, and landfill surveying.

Communication network testing

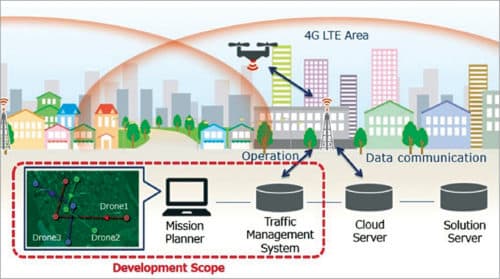

To ensure safety, unmanned traffic management (UTM) systems are being developed to connect and operate multiple drones simultaneously. It is imperative to ensure that the quality of the UTM’s communication network is reliable to have seamless control of the UAVs in the designated areas. This makes it critical to test the network quality at high altitudes before any UTM is successfully deployed or UAV flies in that area.

Testing the quality of service (QoS) and quality of experience (QoE) of LTE networks at flight altitude can help to identify the problem in the UAVs’ path and altitudes such as a lack of data throughput, insufficient network coverage, and high latency, which can pose a problem in UTM’s communication with the UAVs.

RF scanners and QualiPoc Android handsets mounted on a UAV can be used for testing network QoS and QoE. The coverage of a UAV’s flight path at different altitudes can be determined by measuring and plotting network coverage parameters such as reference signal received power (RSRP) and signal to interference plus noise ratio.

Rohde & Schwarz has partnered with UTM vendors for conducting flight tests in different parts of the world to collect information regarding LTE network at varying heights of UAV flight paths. They conducted latency and data throughput tests to identify the potential problems at different altitudes. Looking ahead, 5G will help to improve the UTM needs further, in particular, the latency by using ultra-reliable low-latency communications.

Performance testing

A complete diagnosis of the remotely piloted aircraft is required for reducing damages, accidents, and losses. An accurate and complete analysis indicates weak points, malfunctions, and offers the opportunity to improve the devices’ performance.

This requires a hi-tech mechanism for monitoring and measuring electrical-energy parameters through sophisticated sensors. The main measures are absorbed power, figure of merit (FoM) parameter, power consumption per kg of thrust, weight, and thrust of the drone, energy used, real battery capacity, and centre of gravity position.

The DPM Elettronica’s Drones Laboratory offers a system of integrated services defined as the DronesBench Index (IDB) for the diagnosis, testing, setting, measuring, and certification of professional drones. It allows the compliance of the relative parameters compared to those existing at the time of the homologation of the drone. It can also be used to calculate the power/absorption ratio of the motors with the respective propellers.

DronesBench instruments were developed to monitor energy parameters. They have a sophisticated sensor system to ensure accurate measurements on remotely piloted aircraft (up to 15kg payload). Further, the DronesBench devices allow performing global tests of the specific functions of the aircraft like tracking the spread of a wildfire, searching for a missing person, and detecting toxic fumes before sending in rescue workers.

To ensure the capability, a new standard has been published recently based on more than twenty aerial test methods developed by the NIST (National Institute of Standards and Technology). These are all being standardised through the ASTM International Standards Committee, which includes tests for searching and mapping wide areas, navigating hallways within buildings, and avoiding situations that may interfere with radio communications.

Measurements through drones

Drones are the latest technology deployed for arsenal leak detection, providing real-time identification of leaks and accurate quantification of emissions. Drone-based methane monitoring programs have the potential to help the entire industry reduce emissions by detecting and quantifying methane emission rates coming from individual oil and gas production sites. This technology advancement quantifies emissions and allows you to direct more efficient and effective maintenance activities in the future.

The drone system is outfitted with onboard gas analysers and meteorological sensors, which provide data to the operator while being flown around well sites. By executing a flight pattern that creates a virtual plane downwind of equipment, the technology identifies the total amount of methane being emitted from the site. The system does this by detecting methane passing through the virtual plane and capturing wind vectors in real-time. These variables are then fed into sophisticated algorithms to quantify methane volumes.

Since drones are much smaller than aircraft, they fly at much lower altitudes and can more precisely pinpoint the location of leaks by pairing the data collected with visual information from the on-board video feed.

Nondestructive testing (NDT) measurements require collecting data from locations that are either inaccessible or difficult to obtain due to access issues, safety considerations, or other limitations. The drone-based NDT measurement systems use computer-controlled heavy-lift multirotor drones outfitted with various sensors. It allows flight control to accomplish the precise flying and maneuvers required close to the structure. Thus, a software-controlled flight is crucial for an easier, safer, and faster NDT measurement process.

The aerial robotics platform is an innovative application that utilises existing NDT devices and available drone technologies equipped with a system of complex integrations, custom sensor arrays, PCBs, and software. The system has the potential to improve testing, inspection, and data collection aspects of assets, allowing a better application of science.