“Tyre pressure monitoring, keyless entry, infotainment and immobiliser systems are examples of technologies containing RF signals that are often triggered by external events which create profiles that are intermittent in nature—present one moment, absent the next—and variable over time,” informs Sun. These transient signals are difficult to measure using traditional spectrum analysis tools and require new instruments that can measure time-varying signals in the frequency domain.

“For RF testing, the test instruments used are vector/scalar signal generators, analysers and vector network analysers generally less than 6 GHz,” says Gautam. There are also handheld RF analysers with spectrum analyser capability which can be used to fulfil RF testing needs of the automotive industry.

Intensive tests to maximise safety

The most critical modules are those related to safety. “The automotive industry has always considered safety a critical engineering concern. Indeed, much of this (anti-lock brake systems and electronic control units) is implemented using a new software that has been introduced specifically to increase safety,” shares Sun. Safety is the most critical module in automobiles for which specialised testing is required.

Panikkar explains, “Crash testing is a very important test, and its results are fed back to the designers to offer as much protection to the driver as possible.”

The response of critical modules needs to be studied under different test scenarios and injection of faults. Data received from these tests needs to be analysed thoroughly to determine key conditions when drivers are at greater risk.

“Tools like DIAdem with its crash testing and analysis toolkit offer effective methods to analyse data obtained from such tests,” Panikkar adds. These need to be combined with data acquisition systems for measurement of vibration, impact and other parameters.

New technologies for automotive tests

Test and measurement instruments always work on future orientation. This means that all the latest trends in instrumentation technology reflect immediately on these solutions. All the innovations in automotive technology need innovative test and measurement solutions.

“Miniaturisation of the instruments is one such example. Tests that required an entire bench of instruments not long ago, can now be done with a single instrument. The architecture now also ensures that modifications can be carried out with minimum or no change in hardware,” says Gautam.

Implementation of technologies like ZigBee, Bluetooth, GPS and DVB has increased the diversity of T&M solutions used in the automotive industry now.

Today’s test systems rely heavily on reprogrammable field-programmable gate arrays (FPGAs), which offer flexibility to a great extent. Panikkar shares, “These FPGAs allow for system models to be downloaded onto them. Input/output (I/O) can then be fed directly to these boards and the FPGA mimics the system response. These systems use real-time operating systems in order to achieve deterministic performance and accurately control timing of signals and make synchronised measurements.”

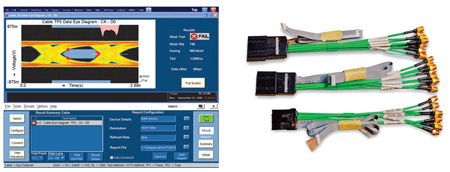

More and more advanced technologies are being adopted in the automotive industry for developing an ecology-conscious, safe and comfortable car. Sun tells, “For example, last June when HDMI 1.4a was released, it was the first time that any advanced digital video and audio technology supported automobiles. There are solutions to test and support automotive HDMI (Type E) and unique direct synthesis capability.”

The convergence of technologies and capabilities inside an automobile has led to test equipment that combine multiple capabilities in a single unit.

“T&M offerings include a wide range of combined solutions that are easy to use and economical. One example is the DC power analyser which combines 1-4 DC power supplies, DMM, oscilloscope, arbitrary waveform generator and data logger in one integrated instrument. And most importantly, it is a modular instrument and hence provides the users flexibility in terms of expansion with need,” Jain says. Thus it ensures optimised initial investments.

Technologies like LXI (LAN eXtension for Instrumentation) have made it very easy and user-friendly to connect various test instruments to a PC and to each other. “The new power supplies and loads with advanced sequencing and high slew rate can help to simulate the charge/discharge conditions for hybrid cars’ charge controllers and electro-motors,” shares Prabhakaran. He adds, “Isolated analogue controls also help the user in testing of critical parameters.”

The ultimate goal

The ultimate goal of any T&M vendor is to provide solutions that reduce engineering costs and time to market while maximising flexibility and long-term investment. The automotive sector has challenging demands on either of the aforesaid parameters.

“Since the failure of the system can cost the human life, a very effective, robust and exhaustive testing is required,” cites Pathak. Agreeing to this, Gautam adds, “This emanates from the fact that vehicles (and their sub-assemblies) are expected to operate in completely uncorrelated scenarios demanding high ruggedisation.” Testing solutions are available that can be used in design, validation, certification, manufacturing as well as service of automotive electronics.

Measurement integrity and speed, test throughput, test system up-time, flexibility and reuse are the specific needs of this industry. Ever-changing market scenarios and increasing competition are leading to improvements in the existing products and testing of new products with almost the same test setup.

The author is a senior technology journalist at EFY