The article looks at the emerging trends and applications in the RF design space which are driving the development of cutting-edge test and measurement tools

VANDANA SHARMA

[stextbox id=”info”]

“A lack of precision is dangerous when the margin of error is small”

—Donald Rumsfeld,the American Secretary of Defense

[/stextbox]

JANUARY 2012: These words hold true for any area of operation where a minuscule error can lead to critical repercussions. RF design testing is one such field where lack of accuracy can lead to the failure of a design project.

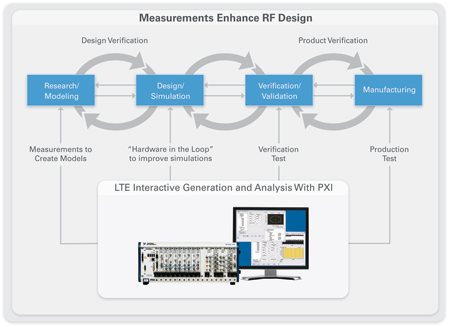

RF designers in fields such as telecom, aerospace and defence focus on building cutting-edge technologies and applications of the future. The test and measurement (T&M) industry is keping up with these developments.

Recent trends

Demand for compact and sophisticated equipment. The latest trends in T&M equipment for RF design include instruments with higher frequency and higher instantaneous bandwidths in a compact PCI eXtensions for Instrumentation (PXI) form factor.

Abhay Samant, senior RF group manager, NI India R&D, informs, “In the recent months, we have seen PXI RF signal analysers with up to 14GHz frequencies, 50MHz instantaneous bandwidth and a dynamic range of 80 db and higher. With very good interactive software support, designers can use these instruments on desktop for prototype design testing and early validation.” Engineers can also use very powerful instrument drivers for these instruments in LabVIEW, C, CVI or .Net to make custom measurements.

Equipment for the next-generation wireless standards. In the next-generation wireless communications standards, we see continued trends of using more spatial streams, wider channel bandwidths and higher-order modulation types to increase data throughput.

“As more sophisticated wireless standards evolve with more complex modulation/access techniques to address the efficient use of scarce resources like RF spectrum and power, demand for T&M equipment for these standards continues to increase. Apart from this, high-speed multimedia standards like wireless HDMI are also driving the need for advanced RF T&M equipment,” says Vishal Gupta, RF applications consultant, Agilent Technologies.

Samant illustrates, “With IEEE 802.11ac, this trend has resulted in the use of 8×8 multiple-input and multiple-output (MIMO), as much as 160MHz bandwidth and 256-quadrature amplitude modulation. With LTE Advanced, support for 8×8 MIMO configurations and the implementation of carrier aggregation to support as much as 100MHz channel bandwidth are also seen.”

However, while the next-generation wireless standards provide obvious benefits to consumers in the form of faster data transfer rates, design and test of IEEE 802.11ac and LTE Advanced radios pose significant challenges.

Tarun Gupta, business development manager, defense and telecom, NI India, explains, “From building transceivers capable of handling a wider bandwidth to packing more antennae on a single mobile device, next-generation standards come with substantially more difficult hardware requirements. As a result, the measurement and instrumentation required for next-generation wireless standards are more challenging as well.”

Equipment for in-line processing of RF signals. Another evolution is happening in the in-line processing of RF signals. Samanta explains, “With bandwidth increasing, integrating processors like field-programmable gate arrays (FPGAs) and digital signal processors (DSPs) with RF modules like vector signal analysers (VSAs) and vector signal generators (VSGs) allows users to react to the device under test (DUT) in real time and make changes accordingly.”

Equipment to generate custom-built signals. Another key challenge before RF designers is to generate custom-built signals (for evolving wireless standards and defence applications) to test their systems without sharing the intellectual property. “Wideband arbitrary waveform generators with RF bandwidths up to 5 GHz and microwave vector signal generators up to 44 GHz provide such solutions. Additionally, new signal analysers with up to 900MHz bandwidth and millimetre-wave oscilloscopes with up to 33 GHz of real-time bandwidth overcome the challenge to analyse these signals,” explains Vishal.

Advanced test equipment for strategic electronics. Strategic electronics systems like radars with better speed and range resolutions are pushing the need for millimetre-wave test equipment touching terahertz-range.

Vishal affirms, “Wide-band signal analysers with up to 900MHz intermediate frequency (IF) bandwidth and 160MHz analysis bandwidth have been introduced. The same is the requirement for testing high-bandwidth future radars and evolving wireless standard 802.11ac. The combination of a wide-bandwidth ARB with a microwave vector signal generator provides flexibility to generate custom waveforms and signals of up to 2GHz bandwidth, 44GHz carrier frequency and waveform for virtually any type of wireless standard and electronic warfare signal simulation.”