Programmable Logic Control (PLC) :

PLC is a digital computer generally used in industry to control manufacturing processes, fully automatic machines, and robotics. It is made highly reliable, accurate, having fast response.

There are various types of PLCs to cater to the specific needs such as machine control, robotics and various types of industrial operations.. At the time of selection of a PLC, functional requirement must be clearly known. Next step may be to study specifications of various make and model. A photograph is given below; just to show how a PLC does looks like.

PLC manufacturers general provide many features as specifications, Few of them

are mentioned below

- Scan time

- System scale

- User interface

- Programing

- Number of Inputs and type

- Number of output and type

- Voltage supply

- Display type

- Memory size and

- Mounting type

There are a number of websites which provide online training for programmable logic control (PLC). The training program may include design, programming, installation, operation, maintenance and troubleshooting.

As far as Robotics is concerned, there are generally following four types of industrial robots for plastics injection moulding machines,

- Sprue pickers

- Pick and place

- Linear robot

- Six axis robot

These robots are built around Electronic sensors, PID and PLC

Electric Discharge Machining:

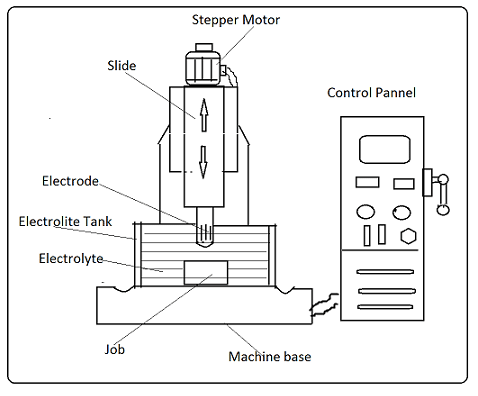

Machine is generally called, ‘Spark Erosion Machine’. It is a good example to highlight unavoidable use of electronics. This machine is very briefly described with the help of Figure 2 & 3

There are many functions of machine which are controlled by use of Electronics (loaded PCBs). Few functions are listed below.

- Fluid level in tank

- Electrolyte temperature

- Electrode touch indicator

- Touch retract

- Spark gap auto adjustment

- Spark current adjustment & auto control

- Rough/ fine finish adjustment

- Adjustment setting ‘Save’ control

- Stepper motor drive

- Synchronization card

- Electrode penetration depth adjustment

- Data storage and retrieval control

- Safety alarm

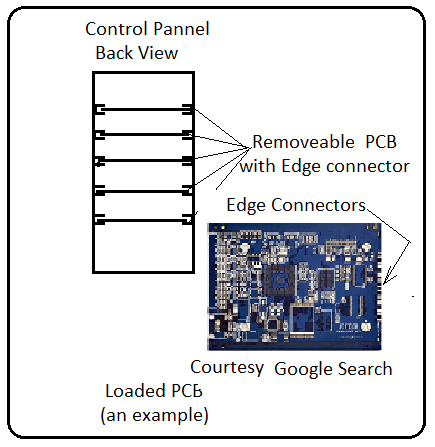

All above-mentioned actions are controlled by dedicated PCBs. Most of the PCB have edge connectors. This facilitates replacement of PCB in case loaded PCB become defective.

Machine users just change PCB and send defective one for repairs by specialized PCB repair service. Often EDM machine supplier handles this repair or replacement. Even recommend some party to carry out repairs. The objective of mentioning this is to highlight that electronics technology is indispensable. Knowledge dissemination is necessary through latest techniques such as eMagazines.