Wrist strap. Standard ANSI/ESD S1.1-2006 defines wrist straps as an assembled device comprising a wrist cuff and ground cord that provides electrical connection of a person’s skin to the ground. The standard document completely describes the parameters for evaluation, acceptance and testing. Though the document describes the whole set of mechanical and electrical parameters over which a wrist strap needs to be evaluated and accepted, the most important parameter amongst all is the wrist strap continuity and resistance which should be one mega-ohm ±20 per cent, for acceptance. The same applies to shoe straps. Figs 3 and 4 show the wrist strap and shoe strap, respectively.

ESD garments. ESD garments such as apron, glove and shoe covers help in reducing the generation of static charge. The standard document ANSI/ESD STM2.1 defines the test methods for determining the electrical resistance from sleeve to sleeve and point to point of static control garment. The resistance range suggested by the document is 1×105 ohms to 1×1011 ohms, but most of the manufacturers do mention that the garments are tested as per ANSI/ESD STM2.1 standard, so do look for that. Fig. 5 shows an ESD-safe apron.

Work surface grounding. It is extremely important to ground the work surfaces, and the work surfaces that we will discuss here are:

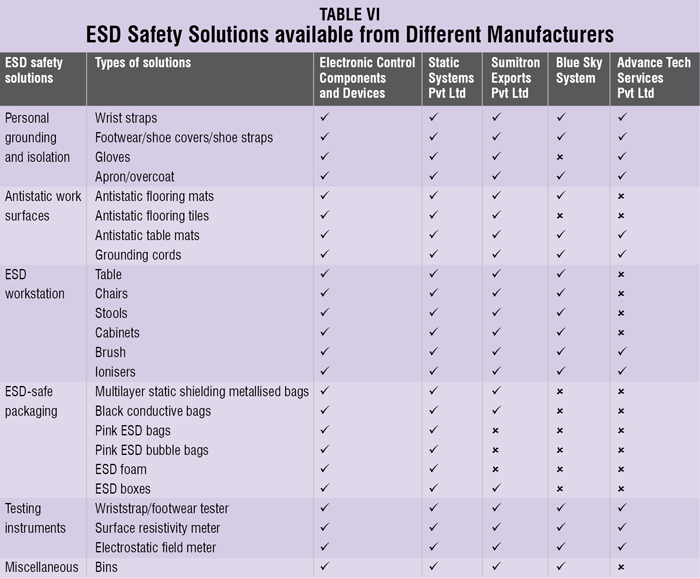

Workstation surface. ESD mats should be used to cover the complete bench-top. The mat needs to be grounded and the best practice is to use metal grounding hardware snaps and ground cords connecting the work surface mat to the common-point ground. ANSI/ESD S4.1 standard provides test methods for evaluating and selecting work surface materials, testing of new work surface installations and the testing of previously installed work surfaces. The guidelines for work surface in the document are mentioned below:

1. Resistance-to-groundable point 1×106 to 1×109 ohms

2. Resistance from point to point ≥1 mega-ohm

These guidelines represent a range of resistance that has generally been proven to provide protection in the manufacturing environment. If the mat’s resistance is too low, static transfers to the mat will be so fast that a spark is created. This spark is an ESD and will damage electronic devices.

If the mat’s resistance is too high, static transfers so slowly that items placed on the mat will not lose their charge. When the item is removed from the mat, it will still have a static charge and be capable of discharging to other items. Fig. 6 shows an ESD mat.

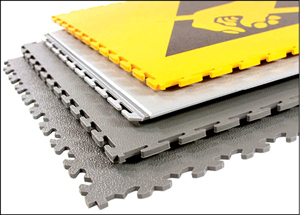

Flooring. First decide on which type of flooring you will use: conductive (electrical resistance to ground range: 2.5×104 to 1.0×106) or dissipative (electrical resistance to ground range: 1.0×106 to 1.0×109).

Dissipative floors are lowest in cost but, if the floor is used as a primary ground for people and carts, a conductive floor should be chosen. ANSI/ESD S20.20 requires a system resistance of a person through the floor and to ground of less than 3.5×107 ohms (35 mega-ohms) when you use the floor as the primary ground. S20.20 allows static dissipative floors as long as the resistance to ground from anywhere on the floor is less than 1×109 ohms and personnel do not generate greater than 100V using the ANSI/ESD S97.2 test method.

There are various options available that you can choose from, such as mats and tiles amongst others, but ensure that whatever you chose it complies with the standards mentioned above. Fig. 7 shows some ESD tiles.

ESD-protective tools and work station

When you are working with sensitive electronic components, you should consider buying all the equipment for your workstation that is marked as anti-static or ESD-safe. The materials mentioned below are optional but can be used for better EPA:

1. ESD table, chairs and stools

2. ESD-safe toolkit (cutter, plier and desoldering pump)

3. ESD-safe equipment such as soldering iron

4. ESD-safe brush

5. ESD-safe tray, bins and cabinets

A bench-top ioniser can also be used to neutralise electrostatic charges at the workstation. This is the only ESD control method available to neutralise electrostatic charges on essential insulators or isolated conductors that may be at the workstation. The required limit according to ANSI/ESD S20.20 is less than ±50V offset voltage (balance).

In addition to that, the discharge time to reduce +1000V to +100V and reduce -1000V to -100V should also be measured. Faster the static elimination time, the better. Do look for one that strictly complies with ANSI/ESD S20.20. Fig. 8 shows a bench-top ioniser.

Proper packaging. Place sensitive items in appropriate protective packaging when transporting or moving to storage. Static protective bags are really an integral part of a static control program. Selecting the appropriate bag can help reduce static damage and save money on costly repairs and rework. The cost of static protective packaging is insignificant as compared to the losses that may be there without them.

There are different types of bags available in the market, but just by looking at them you will not understand their capabilities. Here is how to distinguish them.

Pink poly bags (dissipative poly bags). These bags have the ability to dissipate a static charge to ground and keeps charge from building up on the package. The material is also anti-static, suggesting that it will not charge up by tribocharge. The material’s resistivity is in the dissipative range and is usually 109 to 1011.

Unfortunately, these bags have no shielding ability. A static field or discharge occurring outside the bag will easily penetrate the bag and damage electronics inside.

Black conductive poly bags. Black poly bag is highly conductive as compared to other bags, usually about 103 to 104, and will dissipate the charge very quickly. But, unfortunately, this fast dissipation also creates the possibility of spark at its surface. The material is conductive, therefore it does provide some small measure of shielding. However, there is no plastic layer (dielectric) to isolate a device inside a bag. The charge may be transferred through the volume of the material to the device instead of around the material to ground.

Shield bags. These provide the dissipative and anti-static attributes as well as add a metal shield and polyester dielectric to stop static from entering the bag. The test for shielding demonstrates the difference between the various bags. Shield bags will generally stop 97 per cent of a 1000V static pulse applied to the outside of the bag from reaching the inside. Pink poly bags will stop only about 10 per cent and black poly bags about 30 per cent.

Moisture barrier bags. These provide dissipation, anti-static and static shielding properties together with moisture vapour barrier. The moisture barrier protects moisture-sensitive items and improves long-term storage.

Then there are other products such as pink bubble bags, anti-static foam and anti-static boxes which are generally used in packaging for improving the reliability of the equipment in fields.

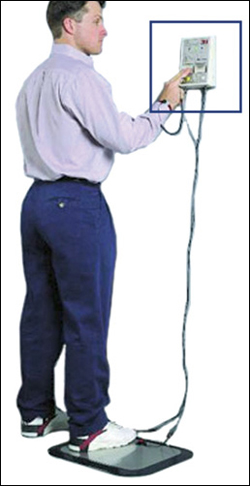

Wrist-strap/footwear tester

The wrist-strap/footwear tester is a highly recommended and widely used testing equipment that can be used to assure the compliance for proper grounding of the workers as required by ANSI/ESD S20.20. Consider buying one to complete your EPA. Fig. 13 shows a wrist-strap and footwear tester.

The author is a technical editor at EFY