Electrostatic discharge (ESD) is the rapid transfer of electrostatic charge between two objects. This normally happens when two objects at different potentials come into direct contact. This static charge buildup is majorly caused by tribocharging and electrostatic induction.

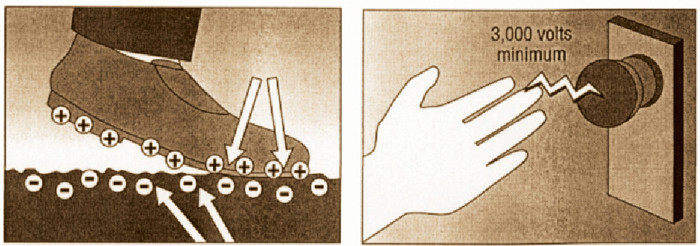

Tribocharging is the generation of static electricity due to separation of electric charges that occurs when two materials are brought into contact and then separated. For example, when you walk on a carpet, the friction between your shoes and carpet results in tribocharging, thus creating a difference of electrical potential that can lead to an ESD event.

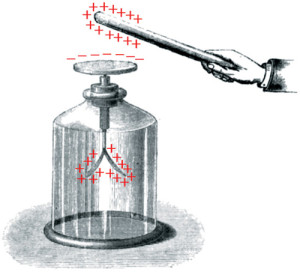

Electrostatic induction occurs when an electrically charged object comes near a conductive object isolated from ground. The charged object produces an electrostatic field that causes electrical charges on the surface of the other object to redistribute as shown in Fig. 2. As such, the net charge on the object is zero but it has surfaces with excess positive and negative charge, so an ESD event can happen from these surfaces.

How does ESD affect electronics

Electronic products are becoming smaller and faster but also becoming more sensitive to ESD. ESD can damage sensitive electronic components, resulting in failures, reduced reliability and increased rework costs. The worst part is that most often the chips get damaged only partially and start malfunctioning later. The cost of a single failure can be astonishing—in defence, such failures can cost lives.

What standards do we have

ESD standards are highly necessary because to objectively evaluate and compare competitive ESD control products. These standards are followed by the manufacturers and users of ESD-sensitive devices and control products, and certification organisations that help them in developing, implementing, auditing and certifying ESD control programmes.

Due to high importance of ESD control in assuring reliability of electronic products, standards for ESD control have evolved pretty quickly. The standards that we have today can be separated in three groups.

The first group consists of those that provide ESD control programme guidance or requirements. These include documents such as ANSI ESD S20.20-2007 Standard for the Development of an ESD Control Program, ANSI/ESD S8.1-Symbols-ESD Awareness or ESD TR20.20-ESD Handbook. Such documents give a broad overview of the requirements of ESD control programme. For more specific understanding of each process you will have to go through the second group of standard documents.

The second group covers requirements for specific products or procedures such as packaging and grounding. For example, ANSI/ESD S6.1 for grounding and ANSI/ESD S541 for packaging materials for ESD sensitive items.

The third group of documents covers the standardised test methods used to evaluate ESD products and materials. These include standards such as ANSI/ESDA-JEDEC JS-001-2010 for device testing, Human Body Model and ANSI/ESD STM7.1 for resistive characterisation of floor materials to name a few.

Basic ESD control system

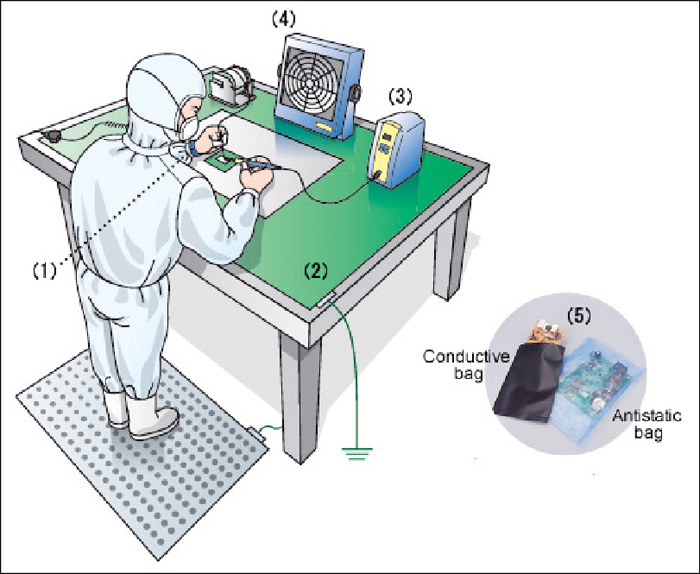

Fig. 4 shows a beautiful example of the basic ESD control system where the most crucial elements are indicated. Just by following these five steps a very efficient electrostatic-protected area can be developed to increase the reliability multifolds.

1. Personal grounding and isolation. A basic ESD control rule is to ground all conductors including people at the ESD workstation. Grounding works very efficiently in ESD control systems and reliably removes electrostatic charges to ground. For such a grounding system it is important that the electrical wiring system of your lab is correct. Electrical outlets need to be checked to verify the correct wiring of live, neutral and ground. Fig. 4 shows only a wrist strap for grounding the worker, but there are other ways like use of shoe straps.

Also, some clothes are a good conductor of ESD charges. Therefore ESD garments are a good idea for added protection. The basic ESD garments used in the electronics industry are ESD aprons, gloves and shoe-covers.

Wrist strap. Standard ANSI/ESD S1.1-2006 defines wrist strap as an assembled device consisting of a wrist cuff and ground cord that provides electrical connection of a person’s skin to ground. The standard document completely describes the parameters for evaluation, acceptance and testing.

Though the document describes the whole set of mechanical and electrical parameters over which a wrist strap needs to be evaluated and accepted, the most important parameter among all is the wrist strap continuity and resistance, which should be one megohm ± 20 per cent for acceptance. The document also suggests the testing procedure for the same. While buying these grounding material, do check if they comply with above-mentioned standard and specifications.