Automatic ranging. This is another useful feature where the device automatically selects a proper range and signal frequency for highest accuracy measurements. So you do not have to set the range every time you want to measure the value of a component. Manual overrides should also be available because sometimes you would need to see the measurements with different number of significant figures.

Hold mode. This is a highly useful feature for taking measurements at those places on the boards where you cannot see the display of smart tweezers. This feature holds the measured value on the display, so you can see it comfortably.

Continuity/open test, diode polarity testing. Smart tweezers that come with continuity testing and diode polarity testing can be very useful while tracing the circuit on a PCB board.

Left/right arrangement. It is almost impossible for a left-handed person to use the smart tweezers configured for right-handed persons. He will see the display upside down. So if you are left-handed, look for the configurability of the smart tweezer for left-hand use.

Some smart tweezers even come with angled tweezer spares, which are even more comfortable to work with SMD components.

Some smart tweezers even come with angled tweezer spares, which are even more comfortable to work with SMD components.

Table I shows specifications of some smart tweezer models from different manufacturers.

Soldering tools

For electronics jobs involving a lot of rework and construction, you will need to use some soldering tools quite frequently.

Soldering iron. Just like multimeters, soldering stations included in toolkits are not really of professional quality. Try to get at least a temperature-controlled soldering station. For good quality jobs you will need a professional quality temperature-controlled soldering station. To understand what to look for while buying a temperature-controlled soldering station, refer the buyers’ guide published in EFY April 2013 issue.

De-soldering pump. A de-soldering pump, also known as solder sucker, is a manually-operated device that is used to remove solder from a printed circuit board. There are sophisticated de-soldering stations available but you cannot ever find them in a toolkit because they are very expensive. De-soldering pump is very handy and does a reasonably good job when you are outside your lab to do some rework.

De-soldering pump. A de-soldering pump, also known as solder sucker, is a manually-operated device that is used to remove solder from a printed circuit board. There are sophisticated de-soldering stations available but you cannot ever find them in a toolkit because they are very expensive. De-soldering pump is very handy and does a reasonably good job when you are outside your lab to do some rework.

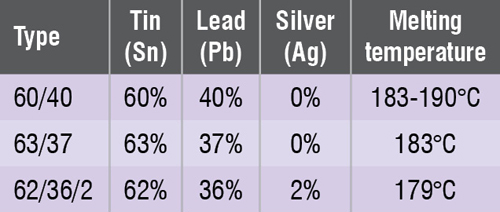

Solder. Solder is a metallic alloy which, when melted by the soldering iron, can join metallic surfaces together. The most common solder compositions used for electronics work have tin (Sn), lead (Pb) and silver (Ag) elements.

The most widely used composition is 60/40. This composition doesn’t melt on a specific temperature. It melts over a range of temperature as shown in the table on previous page. 63/37 is the more modern type, which melts on a specific temperature. The same goes for solidification too. The third composition (62/36/2) is used for professional quality products. For regular electronics works 63/37 is recommended. Most toolkits will have a 60/40 solder, which is good enough in most cases.

how to purchase electronics toolkit