The process of making a three-dimensional (3D) solid object from a digital file is known as 3D printing or additive manufacturing. A 3D object is created through an additive process, which means laying down successive layers of material until the object is created. Additive manufacturing is the opposite of subtractive manufacturing, which is done through cutting out or hollowing out a piece of metal or plastic to achieve the desired shape.

3D printing enables producing complex shapes using less material than traditional manufacturing methods. It starts with a 3D model on a 3D modelling software—users can create one themselves, or download it from a 3D repository. There are four major types of materials used for 3D printing, namely, metal, polymer powder, resin and plastics like PLA, ABS, nylon, PP, etc.

MESH3 is a rapid hardware prototyping platform with capabilities ranging from 3D designing and printing to embedded systems and PCB design.

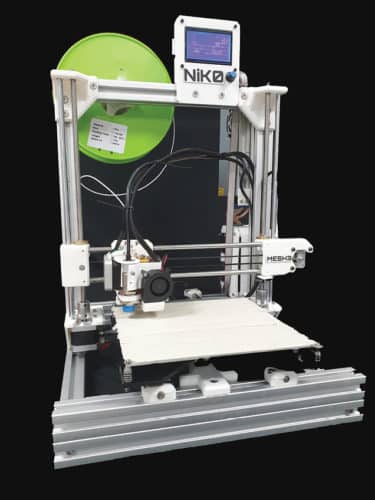

MESH3 has recently released NiK-0 3D printer, which has been successfully adapted and engineered keeping in mind functional and scalable aspects. This printer provides printing reliability and ease of use at only ₹ 37,500.

Keeping up with the hobbyist ideology, the printer is engineered to be hassle-free and completely automatic. It features an inductive sensor, which means the users will never have to worry about levelling the print bed ever again. Moreover, an unconventionally large build volume of 220mm x 220mm x 300mm gives them the freedom to print what they love. This coupled with a direct drive extruder system enables printing with the material of choice. Five sizes of nozzle provide an adequate balance between speed and detail in prints.

Milind M. Manoj, chief executive officer, PupilMesh Pvt Ltd, says, “Implementing state-of-the-art quality construction allows NiK-0 to have a rugged and sturdy frame, while still providing mobility. The design permits the users to upgrade all features of the printer to suit their dynamics. We want users to have full control of their machines and so, we have used easily accessible mechanics and open source electronics.”

There are limitless 3D printing applications in manufacturing, technology and daily life. 3D-printed parts are making an impact on the world today. An increasing number of schools and universities are adopting 3D printing into their curriculum as tools to better prepare students for the future.

3D printing is perfect for prototypes and situations where the product need not be mass-produced. 3D-printed prosthetics are also making people’s lives easier. Automotive and aerospace are using its capability to design unique high-strength parts.

Industries designing 3D printers are working actively to scale structures designed through 3D printers to be used in infrastructure designing. Material experts are working on hard, strong and recyclable materials for 3D printers to scale their use in every industry.