SLS is a very expensive but much faster technology, more effective where multiple parts are required. It also offers increased accuracy which is needed for precision engineering applications, and showcases better print quality than high-end FDM machines.

Colour options. Extruder is the print head or the end of the printer where filament is melted and ejected. In extrusion method of printing, the number of print heads usually determines how many colours can be printed at once.

3D printers can be divided into three based on the colour options:

1. Colour-choice printer. These printers have only single extruder and can print objects only in one colour at a time. This colour is determined by the colour of the material used for printing, i.e., the object would be green in colour if green filament is used and red in colour if red filament is used.

2. Basic-colour printer. These models will have more than one extruder and can print a few colours in a single model.

3. Full-spectrum colour printer. Allows to print an object in a zillion different colours. This is achieved by mixing CMYK colour model—cyan, magenta, yellow and key (black) and jetting it on each thin, plaster-based layer.

Filaments of all primary and secondary colours are easily obtained in the market. In addition to these, exotic colours such as gold, silver and fluorescent are also available.

Cost of parts. cost of parts is expressed in cost per unit volume. Cost of parts is provided by vendors for a specific part, or an average across a group of different parts. These need not necessarily represent the true cost of printing as they exclude the cost of support materials, process waste generated and other consumables used in the printing process.

When the design to be printed is created and fed to the printer software, most of it shows an estimate of the material consumed for that particular project. This will give the user an idea of the cost to produce a particular model. Nowadays, a kilogram of material is available for around Rs 4000.

The lowest cost of parts is found in powder-based printing technologies. Inexpensive gypsum is used as base material and the unused powder is continuously recycled and reused by the device. This results in the reduction of cost by one-third or even one-half compared to other technologies.

Usability, help and support. The model should be user-friendly. Check whether the company offers support by mail, telephone, live chat, etc. many companies do not provide warranty for the printer. So it is safe to double-check that the product you are buying has a warranty cover or not.

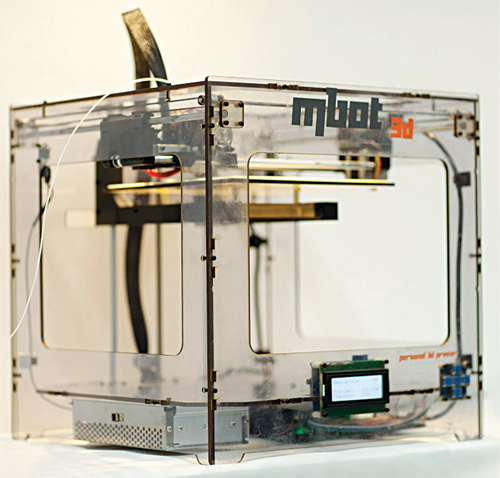

SD card and display support are some other factors one can look for in a 3D printer model. Machines that offer these features can work without being connected to a PC.

Challenges and constraints. A huge limitation in the 3D printing technology is that each object can be printed using only one material. It is not possible to use different types of materials at the same time to create a model. Printing in metal is also relatively new in this field. But extensive research is going on in this field and we should soon see mixed materials and fully assembled products coming out of the printer. “In the future, we are going to start to see mixed materials, electronics 3D printing and conductive materials as well,” says Carine Carmy, director of marketing, Shapeways 3D Printing Marketplace and Community.

Another hurdle is to increase the efficiency of the printing software. A smarter software could give real-time feedback of the project to be printed, optimise design taking into consideration the physical properties required for the product and the properties of material to be used. A lot of investment is being made in this field.

Our Facebook survey suggested that price of the machine is the major issue from a user’s point of view at present. A 3D printer with good specifications can be pretty expensive. One respondee from a professional design background commented on our survey, “3D printers are an expensive fad. For routine mechanical prototype makers, pay off could be sooner, but for occasional mixed technology makers it still does not make sense of buying one.” Alan Campbell, a member of our Facebook page EFY’s Electronics Design Community, commented that he would not prefer buying a 3D printer, “but if someone sets up a (local) shop printing parts made to order, I would give them my business.”

For people like Alan, who are not ready to buy their own 3D printer, there are services to get access to high-end industrial 3D printer machines. Such professional 3D printing services could offer high-quality prototypes in about 30 different materials, at affordable costs.

According to Carine Carmy, the home printer is still fantastic for prototyping, but not yet for end goods. There are several 3D printing service providers present today; Shapeways, 3Digiprints, Clarity 3D, 3D Hubs, KadKraft Systems, C4L, Netgains, Sculpteo, i.materialise, Ponoko, 3Ding and CADD Centre to name a few.

3D printing is improving the manufacturing and production of goods worldwide. It could create fast and easy prototypes at a decent cost. This technology makes it possible for you to hold your ideas in your hand, to create something that never existed before; imagination is the limit. 3D printing is going to revolutionise the world. Get ready for it!

The author is a dancer, karaoke aficionado, and a technical correspondent at EFY. Find her on Twitter @AnuBomb.