Most of our readers are familiar with the conventional type of electromechanical relays, found in many electrical/electronic gadgets. These general purpose relays have slower operating time and limited mechanical life. However, it is inexpensive. Their operating and releasing time lies in between 40Milli Seconds to 15ms.

This article focuses on Vacuum Relays to which most of the readers are not familiar with. It is learned that this device was invented decades ago. The armature and contact leads of a Vacuum Relay are encapsulated with Glass or ceramic materials and complete gaseous substances are pumped out while manufacturing it. Vacuum is the ideal dielectric for high voltage switching. It has extremely high voltage breakdown characteristics (Contact to Contact Voltage holding capacity is ranging from 3.5 Kilo Volts to 70 Kilo Volts) and it provides an absolutely inert and non-reactive environment for switching contacts. Since there is no oxygen or any other gaseous substances in vacuum relays, contacts remain oxidation free. The high dielectric strength of the vacuum permits contact spacing (N/C contact to N/O contact) so close to one millimeter. This least movement permits the use of small, low mass armature and low stress armature releasing spring. This provides high operating time up to 1ms. Use of refractory metal contacts provides exceptional interrupting ability and ensures long contact life.

Vacuum Relays are electromechanical devices, manufactured with two different materials, Glass or ceramic. The solenoid (relay coil) is separately attached with bottom of the vacuum enclosure. So the relay coil can be disassembled as and when it becomes necessary. Normally the working voltage of vacuum relay coils is 12 VDC, 26.5 VDC or 115 VDC. Vacuum relays are available in SPST normally open (N/O) and normally closed (N/C) models, as well as SPDT configurations. Latching relays are available in some models. There are two types of Vacuum Relays.

No Load Switching Relays

As the name implies, this types of vacuum relays can only be switched in the absence of heavy current, because its contact tips are made of copper. It can carry about 40 amperes (DC or 60 Hz). Their operating time and releasing time is so high, nearly 1milli second to 4milli seconds.

Hot make and break type relays

In these types of Vacuum Relays, the contacts are made with materials molybdenum or tungsten. These types can be switched when load current flows without any damage to contact tips. However, they can carry less current, below 20 Amperes. Their operating time and releasing time is in between 6 to 10ms.

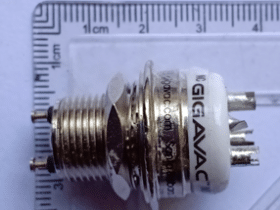

The picture shown below is GIGAVAC’s Hot make and break type Vacuum Relay (Model GH3-SPDT) purchased by the author. It operates and releases in 6ms. It can carry current up to 18 amperes (DC or 60 Hz).

The most important things to remember is that the moving armature and the relay contacts are fitted in highly vacuum enclosure (chamber). As there are no gaseous particles in the chamber, when the relay coil is energized, the armature can move freely in between N/C, N/O contacts without any gaseous impedance with the highest speed of 1 Milli Second. (Please note that the contact gap is 1mm apart). As the moving armature and the contacts are encapsulated in high vacuum, no arching is produced when contacts make and breaks with load current. This increases durability of the contact tips. The mechanical life of a Vacuum Relay is nearly two million times before it fails.

These days we use Solid State Relays (SSR) in the place of Electromechanical Relays. For controlling DC current, DC Solid State Relays are used and for AC currents there is AC Solid State Relays. The AC controlling SSR are available in two models, Zero Crossing type and Random turn on type. If the control voltage is withdrawn, both of them will be turned off only at the point of Zero crossing of the alternating current. So we cannot stop SSR conduction at the exact time predicted. The SSR dissipates heat while in its conduction state and in its off condition there would be some leakage current. The Solid State Relays fail short. This behavior of Solid State Relays makes it impracticable using in electrical safety devices. The vacuum relays have no such disadvantages.

Vacuum relays are manufactured by KILOVAC, GIGAVAC and JENNINGS Technologies of U.S.A. and GLVAC of China. Vacuum Relays find applications in high power Transmitter/Receiver switches, Radar systems, Radio antenna tuning etc. where high speed and high current switching are needed. Since the speed and efficiency of Vacuum relays are highest of all electromechanical relays, it can also be found applications in Robotics, driverless vehicles and power control devices. The Vacuum Relays operating time can further be increased by using silver enameled wire for the relay coil instead of copper enameled wire. If a superconductive environment is provided with the relay coil, there would be abundance chance to increase electromagnetic property of the solenoid and therefore faster operating time of Vacuum Relay.

It is a fact that there are no manufacturers of Vacuum Relays in India. So, Vacuum relays have to be imported by spending a huge amount. This is a difficulty faced by the Domestic Electronic Circuit Designers.

I see them for one big application, switching on/off bathroom gysers as the condition these switches work in are fully humid, such realay which are sealed can handle environment effect, but again they cannot handle currents more than 18amps

Can I use Vacuum Relays @ 1296Mhz RF amplifier switching