PCB123 is a software tool for printed circuit board (PCB) designing. Built with a robust feature set, with over 40-plus years of manufacturing, the tool helps you ease over the design process and get your PCB manufactured from their owners, Sunstone Circuits.

In this article we take a look at what this tool has to offer.

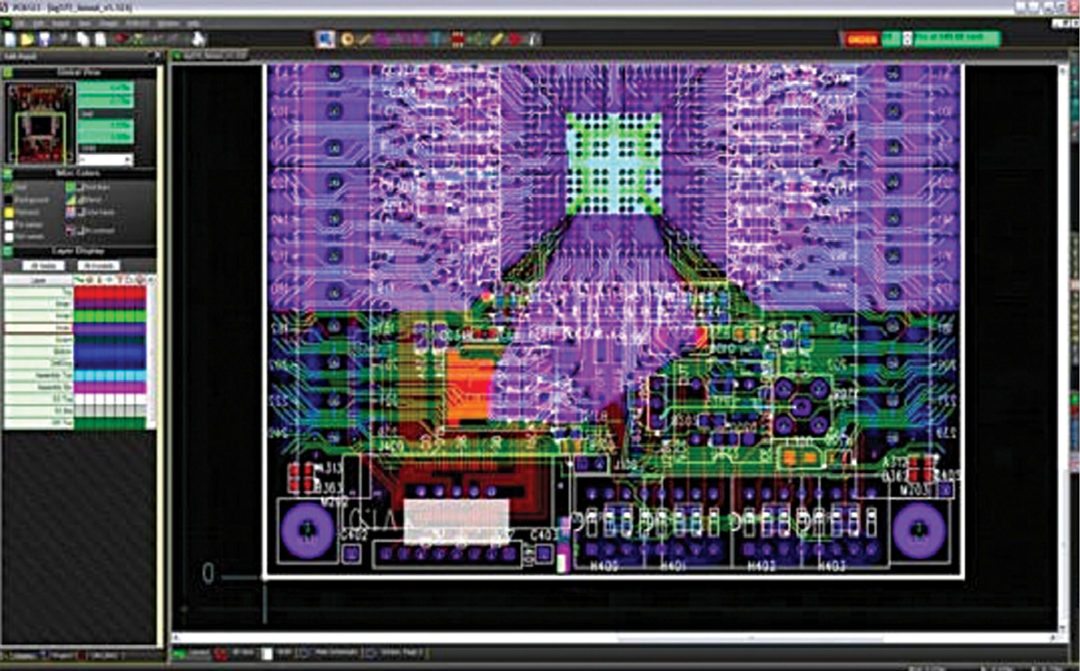

Increased rendering speed for a smoother user experience

With the latest release version 5.2.1, the developers have more effective graphics algorithms built-in, which makes the tool respond to the user’s commands in real-time.

Doing away with the old method of re-calculating all parameters to reciprocate the user’s action, these improved algorithms allow the tool to read polygons off the image file itself. Be it in moving the layout to a new location on the board, zooming in to see a particular part of the layout or scaling up, the tool re-populates almost instantaneously, reproducing the change(s) on the screen with very little delay.

A well-structured schematic editor of PCB123

Every design is constructed on one or more schematic sheets, which can be laid out in a logical way and connected with ports. Alongside is the part library window, which contains libraries from which you can select components for your schematic design.

Selecting the right component is easy as hovering the mouse over each component displays a list of the properties defined for the selected component, including specified part number.

There is also a symbol view that changes with every component selected—a very useful feature when part names are unknown.

A board layout that goes hand in hand

As the schematic is being created, the board stacks up on the footprints of the selected symbols. While these get stacked in a corner, the auto-place feature can be used to centre these on the layout, resulting in what is called a rat’s nest. This is basically a jumble of wires criss-crossing each other to their destination nodes, in keeping with the schematic. Routing between blocks can be done manually or with the help of the tool’s auto-route feature.

Also, next to the layout are sections like different views, general tools and appearance, using which the user can work around the layout, concentrating on the areas that need detailed attention. From the manage parts tab, the user can add footprints to a newly-created multi-section part and bind it to the layout, to be used in further stages.

Have an eye on the price all through

One of the main influencing factors in designing a system is the budgetary constraint. Owners of PCB123, Sunstone Circuits, claim to offer PCB manufacturing services at nominal rates. As they use the tool, users have the option to specify order quantity, and pricing for the same is highlighted. They can go ahead and order the PCB from the same menu at any stage.

There is also a bill of materials (BOM) menu that breaks down the number of components in the design, and the components’ cost. A section specifying Digikey part number allows users to check the latest price online and even place an order on Digikey by automatically filling out the form for them. By a search from Digikey portal, they can cross-reference to make sure that the part specified by the tool is exactly the one they need.

The BOM sheet also allows users to add custom content, to may be order solder or pin connectors to put your PCB into action. A part that is already in the design, like a battery, may not be deleted, but can be hidden. This effectively performs the same action as a delete from BOM table.

Verify before taking plunge

When you click on the order button, the first thing that PCB123 does is do a manufacturing design and fabrication rule check. Users can do the same check at the layout design stage and go deeper into each error to fix it.

The errors and warnings that show up must be corrected or signed off as not being relevant to the design before going in for the next stage. By logging on to their account in Sunstone, users can have an electrical and isolation check, and get assembly done, too. They then have to just send off the order file to Sunstone and wait for the PCB to be ready.

Resources aplenty

The 3D section of the tool lets users visualise how each change they make on the schematic or layout will reflect in the PCB manufacturing stage. As this can be seen not just once the entire design is complete, it puts them at a better place to predict and create according to requirements.

To aid newcomers to PCB123, their website, www.pcb123.com, features a number of videos showing users how to go about the design process. For a regular user, there are videos to highlight the usage of newly-introduced features in the latest versions. With a live chat feature on the website and support on Sunstone website, advanced problems can be solved easily.

For more exciting software reviews: click here

Priya Ravindran is a freelance writer with EFY