There is a very wide variety of industrial sensors available in the market, and selecting the right sensor for an application can be challenging.

Industrial sensors cover almost all the sensor categories including proximity, position, velocity, level, temperature, force and pressure. These find application in extremely diverse areas including industrial process control, energy, aviation, safety and security, automobiles, healthcare and building automation to name a few.

Sometimes sensors form the core elements of products and solutions. These are an important part of the products that define quality, efficiency and safety of the intended application. From bare semiconductor chips and transmitters to complex systems, sensor solutions and technologies exist across the entire value chain. This article covers characteristics of sensors used in industrial process control and monitoring, including wireless sensors, followed by introduction to some leading manufacturers of industrial sensors.

Industrial process control

Industrial process control involves monitoring and control of machinery, systems and processes across a large number of industries including chemicals, pharmaceuticals, biotechnology, energy, water, oil and gas, plastic, paper, and food and beverages. The modern industrial processing and manufacturing systems are highly automated, ensuring that raw materials and energy are consumed in an efficient manner. There are many parameters to be monitored and controlled including pressure, temperature, level, flow rate, humidity, dust, corrosives, explosives, liquids and gases.

Sensors are the first element in a process control and measurement system. Precise control and accurate displacement/position measurement in extremely small scales such as nanometres and picometres has become increasingly significant during the last few years.

The main performance criteria for industrial sensors are sensitivity, resolution, compactness, long-term stability, thermal drift and power efficiency.

Some of the sensors used in industrial process control

Proximity sensors. These can be mechanical, optical, inductive and capacitive. They are widely used in industrial automation like conveyor lines for counting and jam detection, machine tools for safety interlock and sequencing. They are also used in detecting the presence or absence of objects.

Mechanical sensors are basically mechanical switches for on/off operations.

Optical sensors could be light sources like light-emitting diodes (LEDs) and phototransistors. These sensors are essentially non-contact type with no moving parts. They are small, fast-switching, and insensitive to vibration and shock. However, they require alignment, can be blinded by ambient light conditions, and may require clean, dust- and water-free environment.

Inductive and capacitive proximity sensors generally have a short range but are very robust and reliable. Inductive sensors use magnetic properties to detect the presence of metal objects. Capacitive sensors are normally used to detect the capacitance caused by non-metallic objects.

Position sensors

These include encoders and linear variable differential transformers (LVDTs). Encoders are digital sensors commonly used to provide position feedback for actuators. These consist of a glass or plastic disk that rotates between a light source (LED) and a pair of photo-detectors. Plastic disk is encoded with alternate light and dark sectors, so pulses are produced as the disk rotates.

LVDTs consist of a magnetic core that moves in a cylinder. These are commonly used for position feedback in servomechanisms, automated measurement, and many other industrial and scientific applications.

Force sensors

Force and pressure sensors usually act as transducers; these generate signals as a function of the pressure being imposed on them. Force-sensing resistors are two-pin force sensors whose resistance changes when a force, pressure or mechanical stress is applied on the sensor surface. FN3050 sensor from TE Connectivity is a rugged force load cell, highly suited for process industry and test bench applications.

Vibration/acceleration sensors

Ceramic piezoelectric sensors or accelerometers are most commonly used to detect vibration. Triaxial accelerometers are used in mobile systems, cars, turbines and aircrafts. These provide vibration information and position data. Inertial measurement units measure linear and angular motion usually with gyroscopes and accelerometers. These are widely used in aircraft and missile navigation and guidance.

Level sensors

These sensors are very common in industrial process control. Selection of a suitable level sensor depends on its size and geometry. Industrial process control includes hydrostatic and optical level sensors, ranging from simple limit-value detection to precision continuous level sensing. Hydrostatic sensors can be installed as submersible sensors for positioning in the fluid or with a screw thread for attachment to the exterior tank wall.

Industrial wireless sensors

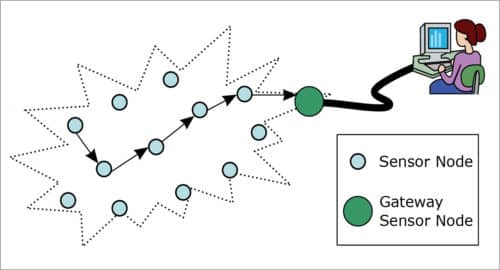

Most traditional sensors usually require a wire or cable to connect with the external instruments. The cable can be copper wire, twisted pair or fibre optic. However, transmission line cables cause signal and power losses. Also, wired network installation is cumbersome and takes much time. Wireless sensors offer flexibility of installation, resulting in improved process monitoring and control and also reduced installation and maintenance costs.In industrial applications, wireless data transmission has been around for a long time. Monitoring temperatures, flow rates, levels and pressure parameters through wireless technology is becoming a popular trend in industrial applications. With the advent of Internet of Things (IoT), wireless sensor networks are deployed in some critical industrial applications. Wireless sensors used in supervisory control and data acquisition (SCADA) effectively address the needs of various industrial applications.

Many companies have been focusing on integrating miniature and low-power wireless radio with sensors. Wireless modules with pressure, flow, and temperature monitoring and control options are being developed to reduce installation and cable costs in large commercial and industrial buildings.

Recent advances in electronics have enabled the roll-out of miniature, low-power and multi-functional sensors that are suitable for short-distance industrial applications. Smart sensors connected through wireless link or wireless sensor network provide unprecedented opportunities for various industrial monitoring and control applications including the environment.

Wireless sensing of acceleration, vibration and velocity provides a more effective way of preventing equipment failures. Wireless sensors are not only wearable but also provide advantages of real-time, continuous, long-distance sensing and ease of operation.

There are many technologies used for wireless data transmission, including mobile phones, Zigbee, GPS, Wi-Fi, satellite, IR, RF and Bluetooth. All industries are different and so are their exact requirements and applications. Hence various standards for sensor connectivity are defined by industrial alliances like HART and Zigbee to meet the requirements of various industrial applications. ZigBee operates at 2.4GHz with data rate of 250kbps. Depending on power output and environmental characteristics, outdoor line-of-sight range of these sensors may be up to 1500 metres. IoT application standards like IEEE 802.15.4 and Narrowband IoT (NB-IoT) enable a wide range of devices and applications.

Industrial applications of wireless sensors

Monitoring machinery and equipment

Wireless sensor networks are deployed to monitor machinery condition-based maintenance. Wireless sensors enable easy access to inaccessible locations, rotating machinery, hazardous or restricted areas, and mobile equipment, which otherwise are difficult to access using wired technology.

Data logging

Wireless sensors are also employed to collect data for environmental monitoring—for example, monitoring the temperature inside a fridge or monitoring the water level in the overflow tank of a nuclear power plant.

Water management

Wireless sensors are suitable for monitoring the quality of underground or surface water and preventing wastage of water. Especially for remote areas having limited infrastructure, wireless sensor networks are ideal as these are fast to deploy and least intrusive for the local environment.

Chemical process monitoring

The concentration distribution of materials during chemical processing can be monitored and controlled using sensors networks. Individual sensor nodes can communicate with other nodes to provide an overall picture of the process. The information may include temperature, pressure, impedance, pH and dissolved gases.

Leading industrial sensor manufacturers

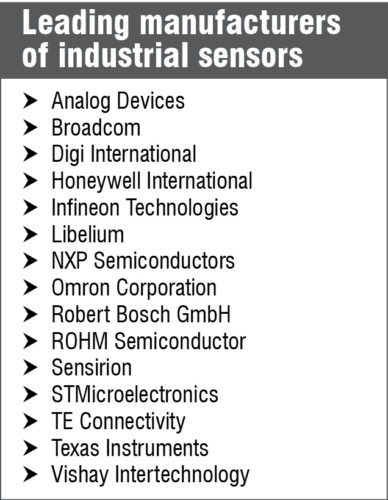

There are many manufacturers in the industrial sensors space, including a few from India. Some major semiconductor manufacturers like Texas Instruments, NXP Semiconductors, Analog Devices, STMicroelectronics and Vishay Intertechnology also manufacture sensors for various industrial applications. Companies like Honeywell International Inc. develop wireless monitoring and control products focused on industrial applications. ROHM Semiconductor offers a broad portfolio of industrial sensors including proximity sensors, light sensors, Hall sensors, capacitive and MEMS sensors. TE Connectivity offers different types of sensors for a wide range of industries including automotive, industrial, medical, appliance and defence.

Plug & Sense devices from Libelium are unique sensors that connect with the most common industrial communication protocols like RS-232, RS-485, Modbus, current loop and CAN bus. These are useful for a wide variety of applications including industrial sensing and automation, military, automobile and remote factory management.

To sum up

Different types of sensors are available for different industrial application requirements. Selecting the right sensor is important for various industrial process control applications. Smart wireless sensors are becoming popular to address various issues in modern industrial applications.