Import/Export DXF. It is possible to import and export every layer and associated items from and to DXF files compatible with commercial CAD such as AutoCAD, IntelliCAD and TurboCAD.

Export IDF. It is possible to export the design created in ZenithPCB to ASCII file containing all the 3D information. This file is compatible with most professional CAD software, making it useful for mechanical designers.

Trace Current Capacity. The Current Capacity option lets you know how many amperes of current a trace could carry, by choosing the empirical formula, foil thickness and temperature rise above ambient condition.

Alternative Bottom Component. This field in component library lets you set the bottom footprint for both wave soldering and reflow soldering.

Obstruct Shapes. It is possible to define areas in the PCB where certain operations such as copper pour, placement and routing are not allowed. Height obstruct option is used for checking against component keep-out areas.

Padstack. New features allow the user to make pad in an offset shape, and with slot holes.

You can make both single-sided and double-sided PCBs using ZenitPCB Layout. The component library has more than thousand footprints. The footprint wizard makes the creating of footprint easier. Design rule checker considers the rules to be followed while placing elements in a PCB, like the clearance between board outline, tracks, pads, components and text.

ZenitParts

ZenitParts is a simple tool that allows you to quickly create and modify parts and symbols for PCB designing purposes. The user-friendly and intuitive UI, very similar to that of ZenitCapture schematic, makes this program easy to understand and use. The created parts and symbols can be easily saved to the library of our choice. It also allows you to modify the items already provided in the library, copy, delete and rename them.

ZenitPCBGerberView

The default file format *.zpc created in ZenitPCB Layout can be exported to Gerber and NC Drill file formats from File > Export and selecting the option required. This opens the Generate Gerber Files or NC Drill Format dialogue box accordingly. Along with the Gerber and NC Drill files, the system creates an ASCII file with the name and folder of the Gerber or NC Drill files. Once this is done, click on the Open GerberView icon from below the menu bar to open the ZenitPCB GerberView window, and it displays the Gerber format according to the ASCII file.

The GerberView has options to hide and view separate layers or all at once. This makes analysing and editing easier for the design. The colour view of each layer can be configured according to the user’s preferences. When Overlay Display Color is activated, it can control the transparency of various layers so that the user can observe more layers at the same time.

Steps for creating PCB design

Here are the basic steps that need to be followed when you are designing a PCN using ZenitPCB suite: First place the components in ZenitCapture. Route all the components. Package the parts and create a netlist. Now create a new project or open an existing one in ZenitPCB Layout, place a board outline (Place > Board Outline > Wizard… / Polyline). Import the netlist from File > Import > Netlist… option. Now you can route the circuit to create a suitable PCB design.

Here are the basic steps that need to be followed when you are designing a PCN using ZenitPCB suite: First place the components in ZenitCapture. Route all the components. Package the parts and create a netlist. Now create a new project or open an existing one in ZenitPCB Layout, place a board outline (Place > Board Outline > Wizard… / Polyline). Import the netlist from File > Import > Netlist… option. Now you can route the circuit to create a suitable PCB design.

On an alternate method, you can directly design without creating schematic, by importing and/or editing components from library using File menu.

Easy user interface and detailed help files

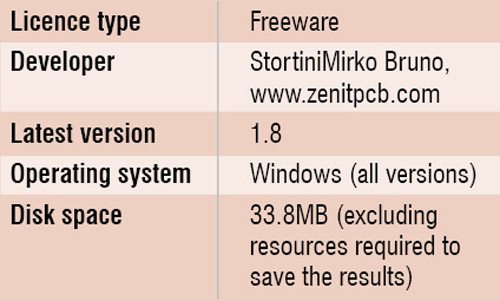

The basic steps for designing using ZenitPCB suite are very simple and require little documentation. But if you had selected to install help file along with the package, then you can get access to an elaborate help file that guides you to create a PCB design right from the beginning. The help window can be opened by pressing the function key F1. The download page of the developer site www.zenitpcb.com also has a collection of video tutorials. Both these would help a novice engineer to get through the design process without much trouble. For more tips, advices and guidance, you could send a mail to [email protected].

The author is a technical correspondent at EFY