Designers portray ideas as reality using a base. Electronic design software serves as the base, or the platform. What if a free design and simulation software gives access to customised PCBs as well? The outcome would be wonderful as designers will have a smooth sail from design to prototyping and production. That’s exactly what Pad2Pad freeware does.

The basics

Pad2Pad is a computer-aided design (CAD) software that was first released in 2007. It runs on Windows 98, XP, 2000, ME, Vista Home Premium, Vista Business and Vista Home Basic versions. You can either create in Pad2Pad, or test your designs in SWPICE program and import the net list into Pad2Pad. What is really exciting about Pad2Pad is that you can order even small quantities of boards and still get silk screen and solder masking. Also, components can be placed directly.

Pad2Pad freeware is updated on a regular basis, and every new version comes with some added advantages.

How it saves time and money

A well-equipped freeware.

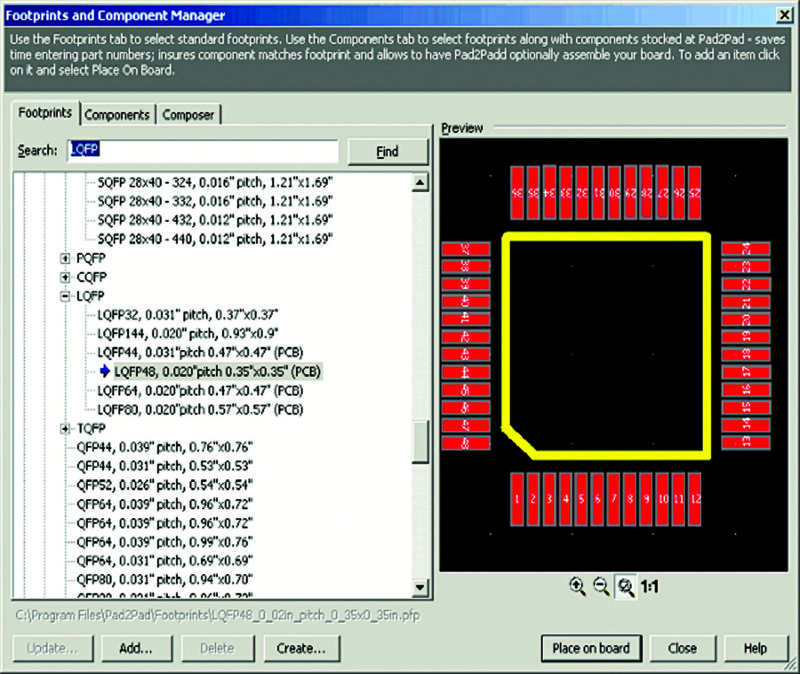

Beginners and hobbyists prefer design software that are free of extra cost and available without license, whereas professionals look out for comprehensive and well-arranged design tools. Pad2Pad is a well-structured freeware tool that lets you access bill of materials, wherein you can add or remove components as desired.

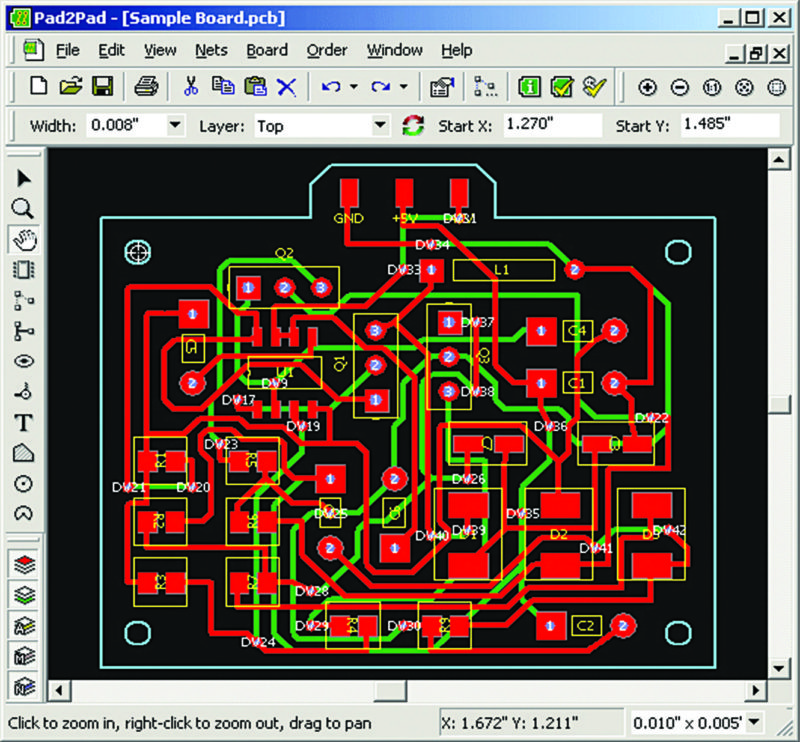

Pad2Pad supports up to 16 layers. You can also build customised footprints as per component sizes. The tool supports both metric and US customary units.

Mechanical data export.

To explain, let’s take the example of an LED light. It takes a driver PCB as well as mechanical housing, heat-sink, screws and washers to make a complete lighting module. If a design engineer does not have the facility of electronics and mechanical data export at once, there would be delay in each process—adding costs while creating clutter. The feature of mechanical data export helps save designers’ precious time. Above all, this freeware lets you select the number of layers for your PCBs.

Design and order together.

After deciding on components and their pads, designers can set an electrical net. This net helps realise connections between components, reducing the chances of errors.

Pad2Pad developers suggest customers to only place small orders initially. Once the test trial is successful, they can place a bigger order. This helps them avoid losses due to a defective design. During the trial lot, the customer can test the prototype for proper working of both the mechanical and electronic parts.

Other than regular in-built features, customers need to specify inner layers of the stack, material’s temperature strength and other such features to get the PCB customised to their requirements. This information helps to avoid conflicts with customers, making Pad2Pad a professional and reliable platform. Pad2Pad prototype and production services also follow IPC standards for safety requirements.

An all-in-one package

You can design, fabricate and even assemble with Pad2Pad. This free simulation tool also comes with customer support, which is a special advantage to designers.

Download latest version of the software