Proview SCADA is a powerful software for sequential control, supervision and data acquisition. Claimed to be the first open source SCADA software, it has been accepted globally. SSAB Oxelösund, the leading manufacturer of quenched and tempered steel, has the largest Proview installation. Ranging from raw materials to rolled plate, its entire production line is supervised and controlled by over 600 Proview systems.

Features

Proview SCADA is a distributed system in which several computers are interconnected via a network such as Ethernet. Programming in Proview is possible using graphical PLC editor or a high-level language like C, C++, JAVA or FORTRAN.

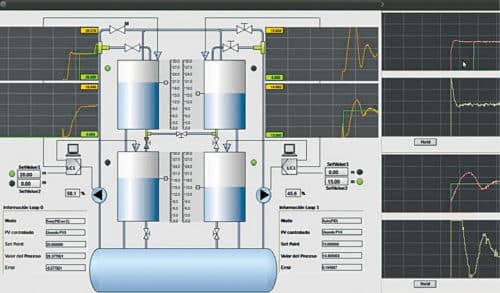

Fig. 1: Proview application in tank control (Image courtesy: http://i.vimeocdn.com)

Other salient features of Proview SCADA include:

1. It is the only control system that can work in object oriented programs. Users can make the programming traditional and simple

2. The system is configured graphically, which helps to make the application simple, flexible and reliable

3. There are no limits to the number of inputs/outputs (I/Os), PLC programs, counters, loops, etc, and the PLC cycle loop is less than one millisecond

4. For connectivity, Proview SCADA supports different protocols, such as UDP or TCP sockets, via Ethernet and Siemens 3964R serially

5. As Proview operates on Linux and supports HLL, it is easier to implement on many I/O systems. It also supports Profinet, Ethernet Powerlink, Modbus TCP, a few USB I/O cards, etc

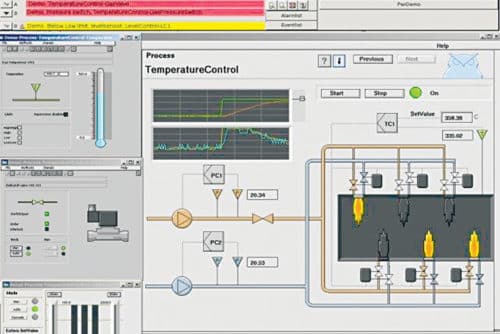

Fig. 2: Proview application in temperature control (Image courtesy: https://sourceforge.net)

Version 5.5.0 vs Version 5.4.0

Proview’s latest version, 5.5.0 has some additional features as compared to the previous 5.4.0 version. Horizontal and vertical marker in XY curve, table curve component, polynomial curve component, Xtt translations and redundancy are amongst the upgrades. Besides, new classes have been added.

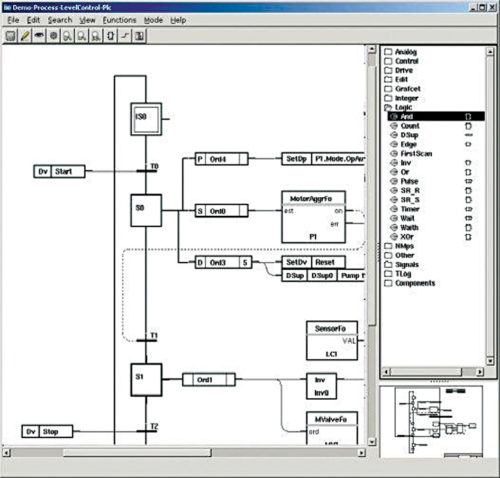

Fig. 3: Demo for process control using Proview (Image courtesy: https://sourceforge.net)

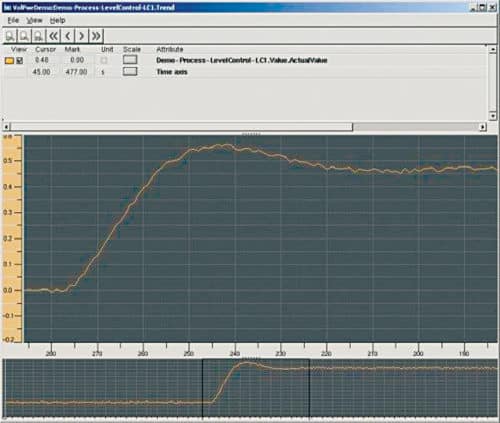

Horizontal and vertical marker in XY curve

Two horizontal marked lines are added in the graph, which are controlled by Trend properties. (These can be connected to analogue signals.)

Table/curve component

With CompCurveTab it is easy to derive the value of ‘y’ in a curve for a specific value of ‘x.’

Polynomial curve component

It is similar to CompCurveTab value, but here the curve is specified with a polynomial, which means for a specific value of ‘x’ on the curve, the user will obtain value of ‘y.’

Xtt tree window to view specific classes

It is a new window that displays curves both in current node and mounted node.

Redundancy

Proview SCADA implements a redundant system with two identical nodes: active and passive. The active node executes the PLC program, while the passive node receives the database and alarm for execution. The PLC thread in the passive node receives the packet and later inserts the data in required objects. This complete communication is handled by rt_redcomm (redundancy communication).

Classes

As the bandwidth is limited, only the data needed for redundancy is included. For instance, description strings will not change in runtime but acquire more space in the packet. So, these would be excluded.

Build and distribute

When the build node is active, primary and secondary nodes are built individually. When distribute node is active, both the nodes are listed.

Fig. 4: Table/curve component (Image courtesy: https://sourceforge.net)

Inference

Proview SCADA is by far one of the most successfully used open source SCADA software, which is quite popular in forums among designers. Originally developed by Swedish manufacturers, it has become a full-fledged yet low-cost solution.

Download the latest version of the software