General-purpose equipment for aerospace and defence

Most aerospace and defence systems and sub-systems are equivalent to commercial systems, so general-purpose T&M equipment satisfying the MIL standards are also used. Every change and advancement in technology is reflected in aerospace and defence missions.

“Remotely piloted vehicles—land, sea and air—scout ahead and stream back data and images. Secure wireless transmissions deliver voice, data and images to war-fighters, who receive real-time intelligence about friends and foes. Advanced avionics and guidance systems ensure precise journeys for military and commercial aircrafts,” expresses Awasthi.

The equipment, though general-purpose, need to be highly accurate to produce perfect real-time information. “The data acquired by the satellite for space station or radar for military intelligence—for analysing remote signals, detecting foreign signals, analysing and ensuring quality of content—should be lossless and real-time,” says Narasimhan.

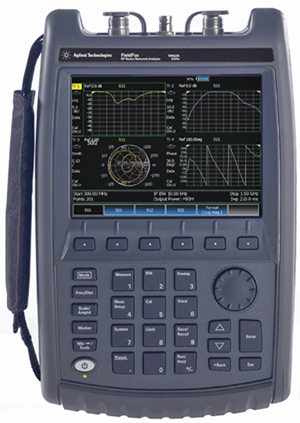

The high-technology aerospace industry is involved in the production of aircrafts, guided missiles, space vehicles, aircraft engines, propulsion units and related parts. “Signal generators, spectrum analysers, network analysers, EMI-EMC receivers and software, oscilloscopes, logic analysers, frequency counters, multimeters and power supplies are the general-purpose equipment required in design and development,” shares Valsalan.

There are a variety of electronic and mechanical tests, such as structural test, functional test, EMI-EMC test, noise, vibration and harshness (NVH) test, and hardware in loop test, performed on the system. High-speed data acquisition apparatus is also an important component of T&M in aerospace and defence.

Cockpit instruments are tested on ground and air. Sabapathi adds, “Bonding tests are done to find the ground resistance between individual modules. It is required to be maintained to avoid static charge build-up on air while the aircraft is flying at a very high speed of around 833 km (450 nautical miles).”

Advanced automatic test equipment (ATE) with multiple test technologies are used to test new generation of multi-layered PCBs having high-density components like FPGAs and CPLDs in packages like BGA, micro BGA and SMD.

Tests specific to aerospace and defence

Certain technologies such as structural testing, radar and cryogenics are specific to this segment. The aerospace & defence industry itself creates test equipment and simulation environments or works with T&M manufacturers to create specific solutions. The aircrafts and space vehicles have to undergo structural tests to ensure correct behaviour under extreme conditions. Communications and security and surveillance are important part of the aerospace and defence industry, and their requirements are very specific.

Structural tests. An aircraft undergoes several tests before it is considered ready for flight. Structural tests are performed on the airframe and the requirements are really complex. There needs to be tight timing and synchronisation, high channel counts, real-time and post-acquisition signal processing, advanced control algorithms, data management and advanced visualisation. To fulfil these requirements, you need an extremely advanced test system that offers extensive engineering resources, and can be expanded and customised to meet the changing requirements. At the same time, it needs to be cost-effective.

Semancik shares, “Equipment available today have set a new standard of performance for stress and fatigue testing. Independent high-resolution analogue-to-digital converters, extensive software-selectable filtering and independent signal conditioning paths provide exceptional accuracy and reliability.” Many equipment deliver cost-effective price per channel performance with both high-quality static and high-speed strain gauge measurements in critical test applications.

“When it comes to satellite and its sub-systems, “getting it right the first time” takes on a larger meaning with satellites going into earth orbit or travelling into deep space,” says Awasthi. A combination of software-simulated environment and hardware is used to ensure the quality and reliability of the device under test.

[stextbox id=”info” caption=”India’s aerospace & defence industry”]

The Stockholm International Peace Research Institute (SIPRI) Yearbook 2010 ranks India ninth in the list of the world’s top 15 military spenders in 2009. India is also one of the six countries in the world that undertake space launch. Certainly, India’s aerospace and defence industry is growing rapidly, ever since the government initiated its open skies policies.

“In 2001, the government allowed 100 per cent domestic private investment in the defence sector upon obtaining an industrial licence and FDI of up to 26 per cent. Allowing private investment has begun to attract a number of Indian companies into the sector. The introduction of the defence offset policy in 2006 and significant liberalisation in 2008 has provided significant opportunities for Indian companies entering the sector,” shares Gautam Awasthi, general manager, marketing, Agilent Technologies.

“As the culture of indigenous designs grows in India, T&M manufacturers are excited and looking forward to provide latest solutions for safe and high-quality developments,” says Jon Semancik, director of marketing, VTI Instruments.

“India is consistently investing in defence and most of the companies look at India as a huge market. Being a developing country, it is also a critical market. Innovation with cost-effectiveness can be a better solution in India,” says Naresh Narasimhan, pacific technical marketing manager, Tektronix.

“Leading companies like Boeing and Airbus have their own maintenance, repair and overhauling facility in India. But we are still in prototype stage as far as our own aircraft design is concerned. It will be a great achievement when Thejas/LCA aircrafts fly on our airspace,” shares S.R. Sabapathi, chief executive officer, QMAX Technologies

[/stextbox]