As manufacturers struggle to reduce their product development cycles in order to stay competitive, test automation is seen as the best strategy to save time and improve product reliability, which ultimately results in cost savings. This article looks at the latest trends and solutions in T&M automation

Rapid advancements in semiconductor technology giving us smaller chips with even more performance, are driving the implementation of cutting-edge functionality in electronic gadgets. Today, mobile phones are not just simple telephones but mobile entertainment systems providing embedded features like LTE, 1020p video playback, GPS, GLONASS, WiFi, Bluetooth, wireless charging and digital camera.

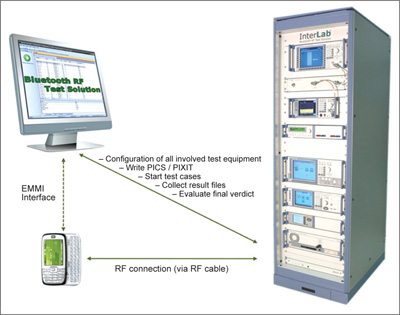

“Test automation is required to cope with a large number of complex measurements in production houses and test labs within a reasonable amount of time and, in addition, allow overnight or weekend regressions. Scripts are coded with series of commands to control instruments remotely and run a measurement routine without human interaction,” says Nidhi Sharma, assistant manager-product support & applications, Rohde & Schwarz India.

In this cut-throat electronics market where drastically reduced product development cycles are still expected to bring out reliable devices, the primary drivers to a successful product are speed of test and quality control.

Stephen Hire, GM, Aeroflex Asia, explains trends in consumer, business and defence markets that are driving the ever greater need for complexity: “First, there is product and component complexity. Many of the calibration and verification stages in modern electronic equipment can only be performed through a tight interaction of test equipment, software adjustment and device control, which more or less mandates automated processes.”

“Secondly, a latest smartphone contains few items that can be easily replaced or repaired in an authorised service centre. So to avoid high costs of returning units to the factory, maximising the quality level through rigid process control is crucial for managing total costs,” he adds.

In defence electronics, pressure is even greater on test engineers. Thankfully, systems such as microwave test systems are available that can be used to make tens of thousands of measurements on mission-critical radar systems over multiple frequency points at a very high speed. So defence forces can be certain that there are no gaps in performance. Automation also enables end products to go through the same rigorous testing in the maintenance stage, ensuring that these high-cost systems do not degrade over time.

Testing during design

A study conducted by researchers at NASA Johnson Space Center stated that finding a product defect during production was 21 to 78 times more expensive than finding it during design. Increasing the test coverage during design can bring about a dramatic reduction in relative cost to repair defects.

Satish Mohanram, technical marketing manager, National Instruments India, says, “The only way to get better at this is to be able to automate the test and have a reconfigurable test system in which multiple test cases can be deployed. Test and measurement has started to move earlier in the product development cycle, and with software defining most of the product’s functionality, embedded software validation is also becoming an important focus area. This is made possible with a new approach called ‘in-loop testing.’”

From the user perspective, the earlier manual testing methodology had error and cost drawbacks. Since the system was manual, the arrangement always presented gauge repeatability and reproducibility (GRR) errors in the system. In addition, operator costs were directionally proportional to T&M complexities.

“Nowadays, T&M automation solutions have evolved to reasonably low-cost, semi-automatic and fully automatic solutions. Users are seeing this as a boon for their T&M requirements. These tools not only save manpower costs incurred by users but also help in ensuring 100 per cent accuracy with increased throughput,” explains T. Anand, managing director, Knewron.

Increased flexibility

General-purpose operating systems like Windows and Linux, coupled with affordable, easily available performance hardware, have increased the flexibility of off-the-shelf instruments, leading to customised and application-oriented solutions.

“Providing test application solutions customised or otherwise is one domain where product companies look to leverage and extend their technical expertise to provide more than just the products to their end users. The term ‘solution’ is not well defined, since the application requirement of one customer may be different from another. Solution would normally mean taking necessary steps to get the customer to where he intended to be in the first place when he decided to procure your test instruments. This will, at times, require development of a tailormade application where engineers from the product company need to work closely with engineers from the end user company,” explains Navjodh Dhillon, application engineer, Agilent Technologies.