[stextbox id=”info”]

Nowadays, T&M automation solutions have evolved to reasonably low-cost, semi-automatic and fully automatic solutions. Users are seeing this as a boon for their T&M requirements. These tools not only save manpower costs incurred by users but also help in ensuring 100 per cent accuracy with increased throughput”

— T. Anand, managing director, Knewron

[/stextbox]

[stextbox id=”info”]

Many of the calibration and verification stages in latest electronic equipment can only be performed through a tight interaction of test equipment, software adjustment and device control, which more or less mandates automated processes”

— K. Stephen Hire, GM, Aeroflex Asia

[/stextbox]

[stextbox id=”info” caption=”Features to look for in T&M automation”]While there are certain basic needs that every T&M automation solution should meet, some features are critical from an augmentation and futuristic point of view:

1. Real-time monitoring capabilities

2. Faster response capabilities

3. Programmability

4. Scalability

5. Reliability – repeatability & reproducibility (R&R)

6. Portability

These features not only help design firms in differentiating their products and solutions but also provide larger support in future applications, scale-ups and servicing. They substantially improve automation quality and reduce costs.

—T. Anand, managing director, Knewron[/stextbox]

Mohanram adds, “Most standalone instruments cannot change their functionality as fast as changes in the device under test (DUT) due to the fixed user interface and firmware that must be developed and embedded in the instrument. Thus test engineers are turning to a software-defined approach to instrumentation so that they can quickly customise their equipment to specific application needs and integrate testing directly into the design process. Not only does this approach provide flexibility, it also gives test engineers the ability to take advantage of the performance provided by the latest PC, CPU and bus technologies.”

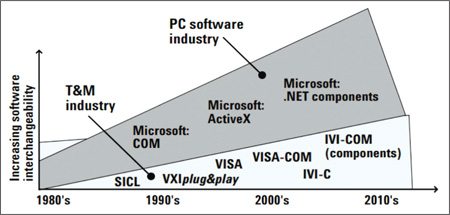

The new trend of utilising tools based on .NET framework, ActiveX and Java has allowed developers to target all common operating systems like Windows, Linux and more, enabling rapid application development by leveraging the huge amount of existing knowledge already available.

“This has enabled development of well-tested, stable and reliable applications built on proven frameworks. Apart from the available graphical programming environments, languages like C# and .NET provide just the right balance between flexibility and ease of use. Programming with text-based languages is not difficult anymore with most IDEs supporting automatic skeleton code generation, cutting down development time and effort and enabling rapid creation of applications for customisation and test automation. Test developers can take advantage of powerful hardware, including multicore processors in general-purpose computers, to take application performance to unprecedented levels,” adds Dhillon.

[stextbox id=”info”]

Test engineers are turning to a software-defined approach to instrumentation so that they can quickly customise their equipment to specific application needs and integrate testing directly into the design process. Not only does this approach provide flexibility, it also gives test engineers the ability to take advantage of the performance provided by the latest PC, CPU and bus technologies”

— Satish Mohanram, technical marketing manager, National Instruments – India

[/stextbox]

Standards bring order to chaos

Industry standards have brought a new level of consistency in software and hardware design, and taken uncertainty out of reusing application libraries and changing vendor-specific hardware.

Dhillon explains, “The end user can now focus on the requirement rather than being limited by a single vendor’s hardware. He can mix and match between hardware from various vendors to choose the hardware that exactly fits his requirement and yet be able to integrate them in one test system with a single application controlling and automating the entire setup. This is quite different from the situation about two decades ago when there was no unifying platform and vendors struggled to get a newer variant of their own hardware to work with their software framework. Of course, inter-vendor operability was a far cry at that time.”

PXI seems to be the uniting standard for most T&M equipment.

Hire explains: “The PXI standard moves automation forward in a number of ways. First, with a separate PC controller and high-speed Ethernet, test speed improves. The ability to upgrade the PC processor to take advantage of faster models also delivers valuable and cost-effective improvements. In comparison, traditional test equipment were stuck with the original processor with which these were designed and an upgrade usually meant replacing the entire instrument. When a factory is producing several million products a month, even a 2-3-second speed gain from improved processing power makes a large cumulative difference.”