This reference design offers a comprehensive and efficient solution for automotive lighting applications. It combines flexibility, cost-effectiveness, and robust performance to meet the demands of modern automotive lighting systems.

Automotive front-light LEDs, known for their energy efficiency, longevity, and superior illumination, have become the standard in modern vehicle design. These LED systems offer significant advantages when paired with a single-edged primary inductive converter (SEPIC) topology. SEPIC topology allows for a wide input voltage range and maintains a stable output, making it ideal for automotive applications where voltage fluctuations are common. This combination ensures consistent and reliable lighting performance and enhances the overall efficiency and durability of the automotive lighting system, thereby contributing to safer and more reliable vehicle operation.

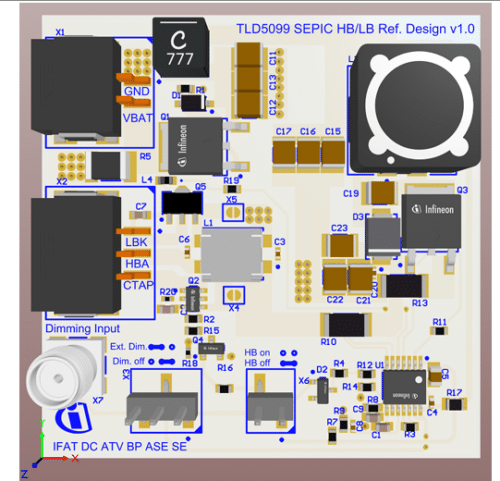

The Infineon Automotive Front Light High Beam/Low Beam Reference Design Z8F68834278 utilises the TLD5099EP, a versatile DC-DC controller from the LITIX Power family, to implement an automotive front light system. This design uses a current-controlled buck-boost SEPIC configuration to drive both high beam (HB) and low beam (LB) LEDs with a single DC-DC channel, offering a cost-effective solution for entry-level LED headlamps. The controller supports multiple topologies, enabling independent or simultaneous HB and LB operation, and features PWM dimming for brightness control and derating under extreme conditions. It includes advanced diagnostics, transient robustness, and verified EMC performance per CISPR25 standards, with detailed thermal performance guidance. The IPD60N10S4L OptiMOS-T2 MOSFET ensures efficient power delivery, while the IPD50P04P4L-11 OptiMOS-P2 MOSFET provides reverse battery protection, enhancing system resilience.

This reference design is suitable for automotive front lights, including high- and low-beam configurations, daytime running lights, turn indicators, and motorcycle headlamps. The power stage is configured in a current control mode to provide the necessary output power to the LED strings, with a PI filter at the input and a standard mode choke at the output to ensure EMC compliance for both conducted and radiated emissions. The HB activation circuit allows for flexible operation modes, either driving only the LB or a combination of LB and HB, supporting various lighting scenarios and enhancing the overall functionality of the headlamp. PWM dimming is implemented to regulate the intensity of the LED strings, and this feature also supports a derating strategy, reducing the power delivered to the LEDs under extreme operating conditions to prevent overheating and ensure longevity. The switching frequency of the power stage can be configured using either the integrated oscillator with a spread spectrum modulator or an external clock source.

Infineon Technologies has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.