The HVIL reference design enhances safety in high-voltage environments with comprehensive fault diagnosis, configurable settings, and robust interlock features.

In hybrid or electric vehicles (HEVs, EVs), systems such as battery management, traction inverters, DC-DC converters, and onboard chargers operate at high voltages and therefore require a high-voltage interlock loop (HVIL). This loop is a low-voltage, low-current circuit that monitors the integrity of the connectors. It checks whether connectors and wires are properly connected, disconnected, have a short-to-battery fault, or a short-to-ground fault. When the HVIL detects a fault, it sends a signal to the vehicle’s safety system to ensure the high-voltage components are safely managed. This setup encompasses both the generation and monitoring aspects of the HVIL system. Texas Instruments (TI) has introduced an HVIL reference design to streamline the design process.

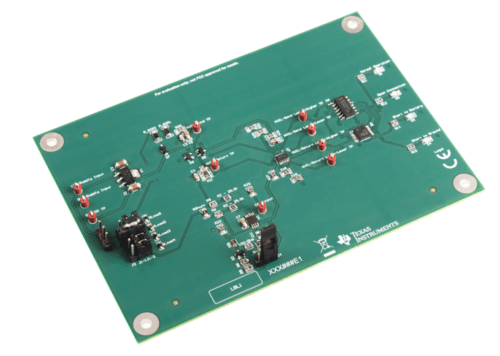

The HVIL reference design offers a comprehensive set of features for interlock loop fault diagnosis, complete with LED indicators to display various states: closed connection for normal operation, open connection, short to battery, and short to ground. It includes configurable constant current generation and options for either analog or digital output signals. Additionally, the system allows for adjustable thresholds in fault state monitoring and employs a unidirectional interlock system.

HVIL connectors are engineered to keep the HVIL signal circuit separate from the high voltage power delivery circuit. As connectors are detached, the HVIL signal circuit is interrupted before the high voltage power, alerting the battery management system (BMS) to any disconnections. This prompt notification allows the BMS to cut off high voltage power swiftly, preventing arcing and protecting against potential hazards from loose wires.

The HVIL system’s functionality hinges on a low-voltage, constant current signal that travels independently through the cables connecting the high voltage battery to various subsystems. Its design includes a constant current generator, a current sensing block, load connectors and clamps, a modified window comparator, and digital logic gates, with each component’s design and function detailed throughout the reference design.

Beyond automotive applications, HVIL technology is also employed in various industrial settings that involve high voltages, such as in heavy machinery in factories, high-voltage smart grids, and other heavy electrical installations. Its use in these contexts helps prevent harm to both individuals and equipment during operation.

The multiple subsystems, including the traction inverter, DC-DC converters, and onboard charger, are connected in series to the HVIL circuit, each operating under high voltage with a requisite interlock loop. Alternatively, these subsystems can each be equipped with their own unique HVIL circuit, connecting to one subsystem at a time to ensure safety and functionality.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, assembly drawing, printed circuit board (PCB) layout, and more. The company’s website has additional data about the reference design. To read more about this reference design, click here.