Here is a simple DC electric motor variable speed controller circuit that can be configured to control the sweep rate of automobiles’ windscreen wipers.

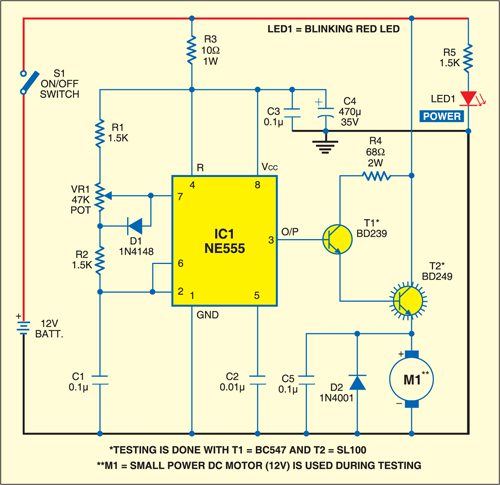

The circuit comprises a timer NE555 (IC1), medium-power motor driver transistor BD239 (T1), high-power switching transistor BD249 (T2) and a few other discrete components. It is configured for automohttps://www.electronicsforu.com/resources/learn-electronics/555-timer-working-specificationsbile usage with the negative terminal of the power supply connected to the ground.

Motor speed controller circuit

Here IC1 is wired as a low-frequency, free-running astable multivibrator with pulse-width modulation (PWM) dc motor speed controller output. The R-C components like R1, VR1, R2 and C1 determine the frequency of oscillations.

Potmeter VR1 works as the master speed controller for the motor. Components R3, C3 and C4 decouple the DC supply of the oscillator. A blinking-type red LED (LED1) is used for visual indication of power-’on.’

When the wiper arm of potmeter VR1 is in top position, capacitor C1 charges through R1, R2 and D1 and produces a pulse train at the output of IC1 with long negative and short positive pulse widths. Therefore the motor speed is slow. On the other hand, when the wiper arm of VR1 is at the bottom position, C1 charges through R1, R2 and VR1 and discharges via R2. The resulting pulse train has long positive and short negative pulse widths.

Now the motor rotates at a high speed. The output at pin 3 of IC1 is fed to transistor T1, which, in turn, drives the DC motor through high power switching transistor T2 at the selected speed. Resistor R4 limits the base current of transitor T2.

Diode D2, connected in antiparallel with the DC motor, limits the back e.m.f. generated by the rotation of the motor. Capacitor C5 suppresses parasitic oscillations.

Construction & testing

The motor control circuit can be powered by 12V DC supply directly from the vehicle’s battery. For convenience and safety, enclose it in a small metallic cabinet. A medium size veroboard will do for construction.

Use a good-quality DIP socket for IC1. Finally, do not forget to add a suitable heat-sink for transistor T2.

Types of DC Motors

- Brushed Motor

- Brushless Motor

- Servo Motor

Uses of DC Motors

- Small-sized DC motors are used in tools, toys, and various home appliances.

- Large-sized DC Motors are used in Manufacturing units, electric vehicles and elevator.

Did i can use 6 volt dc motor and 9volt battery

And the use of heat sink is compulsory