Fire sensors are essential elements for detecting fires in homes accurately, quickly and for reliably accomplishing both first-order firefighting and second-order disaster prevention. To effectively design a smoke sensor system, the following functions are required:

1. Capable of prompt discovery of fires. This is essential for minimizing the damage, recognizing that with longer, bigger tunnels, the number of cars passing through will be high and much time is required for restoring service after the fire; and

2. Accuracy in identifying the point of fire.

The main methods of detecting fires include: detecting the infrared rays generated by the flame, IR scattered light, detecting the temperature rise caused by the fire etc. Let’s explore some sensing methods that can give a good idea of normal fire detection methods. Then we will learn how to correctly design a DIY smoke sensor system.

As sensors of infrared rays, CO2 resonance radiation detectors can be used. This type of detector detects the unique spectrum of carbon dioxide gas which is generated when material is burned and senses a fire. Because detecting the infrared rays generated by a flame is a straight forward method, fires are discovered immediately. Customarily, such sensors are installed every 25 meters and thus the point of origin of the fire can be identified easily.

We have an array of sensors that detect rise in temperature. The advanced temperature sensors are using optical fibers. They can add a great value in making the fire systems sensitive. Using optical fiber temperature sensors, the temperature at any desired point on an optical fiber can be measured. However, the heat must reach the sensor panel and hence detachable sensors are required, the temperature rise may be small and combined logic of fire-smoke sensing can be used. This is a must have device that can save lives, on top early detection poisonous gases generated by the fire is also recommended. For this reason, such sensors may be effective means for accurately grasping the total situation of a fire in a tunnel, when used in combination with an infrared type fire detector.

Other types of fire detecting sensors include smoke detectors which detect reduction in light transmitted due to smoke and methods which use modern cameras. In the case of smoke detection, it has the disadvantage that it is hard to identify the fire point because smoke disperses through the lower areas. Also, now-a-days with Artificial intelligence even more lower cost systems were developed, by means of image processing via CCTV cameras, the software monitors the effect of light disturbance. The turbulent air becomes dominant and resultant change of image is detected in case of fire. The camera sensing faces issues if there is dark smoke, where IR camera systems work well. But if infrared cameras are used, the issue of high cost is a consideration.

Development of Fire Detectors

In the field of fire detectors, the IR reflectance models has a long history and significantly works well. In the specific area of CO2 resonance fire detectors, the factors DIY designers must consider are

1) Battery life

2) Sensing accuracy

3) Alarm loudness

4) Fire retardant housing

Out of these battery life is critical factor and hence smaller microcontrollers must be used. There are custom ICs for photoelectric detection but that limits the configurability.

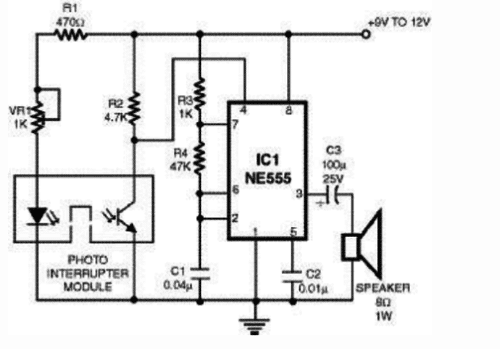

Let’s see an example circuit:

In the absence of any smoke, the gap of photo interrupter module is clear and the light from LED falls on the phototransistor through the slot. As a result, the collector of phototransistor is pulled towards ground. This causes reset pin 4 of IC 555 to go low. Accordingly, the timer is reset and hence the alarm does not sound.

When smoke is present in the gap of the photo interrupter module, the light beam from LED to the phototransistor is obstructed and sets alarm.

The circuit has its own set of problems

It cannot be housed in compact case. This circuit uses like the bigger sized parts viz. the bulky speaker which is not suitable for compact product size.

The biggest defect is the power drainage that DIY guys don’t consider. The LM555/NE555 standby current is typical 6 mA maximum. This makes the battery to drain in few days. The DIY sensor becomes useless. An adoption to better design is to use smaller microcontroller like Attiny85. This can have sleep mode when no operation is needed. Polling sensor at intervals is the way to go.

In intermittent operation is recommended with a factor of 800 the operating current to be reduced to 20mA/800 = 0.025mA plus the current that is drawn in sleep mode 0.05mA.

Now with 2000mA battery/ (0,025+0,05) we come to 27000 hours lifetime which is about 3 years. There are many small controllers to do this.

The ATtiny can reach about 1uA in low-power sleep. Because we only need to periodically check for smoke a rate of pulse can be selected every4seconds after that put the ATtiny into sleep and wake it up every once and awhile.

For this watchdog timer is good, usage as follows:

A watchdog can reset the processor when it gets locked into an endless loop – also known as going off into the weeds. This is a good way to protect a project needs to run all the time without user intervention.

A watchdog can wake the processor from deep sleep. When we put a microcontroller into deep sleep, we can use the watchdog timer as an interrupt, causing the processor to return to normal 8MHz (without a full reset).

The watchdog is just a counter. When that counter gets to the size the user specifies, the processor will either reset or an interrupt will be triggered. Reset can be useful (as explained above), but an interrupt is what we need.

Sample code is very easy to understand.

setup_watchdog(6); //Setup watchdog to go off after 1sec

sleep_mode(); //Go to sleep! Wake up 1sec later and check smoke

A detailed code can be found in sparkfun site URL

The sensing accuracy can be test verified, a distance of 2 meters is a good reference to test.

The alarm should be loud enough to hear must reach 3 rooms so that the protected people can escape on time. Also, to accommodate this loud beeping device piezo buzzers are best choice.

The cases to be used are recommended fire-retardant cases.

Place the smoke sensors in a metal shell separated by air, very simple, kept on tape the circuit and battery. Use a dry 9v to be safe any lithium will explode in case of fire.

CO2 Detection

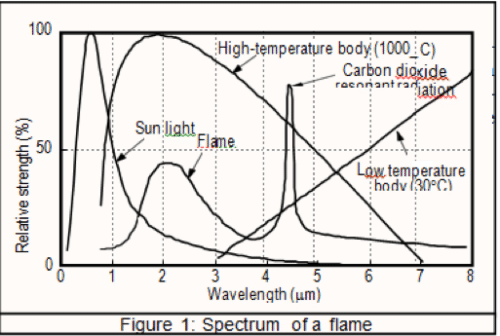

The method employed by CO2 resonance type fire detectors, because it detects the resonant radiation of the carbon dioxide gas generated in a flame, has a high level of detection accuracy. The spectrum of resonant radiation of the carbon dioxide gas generated when materials burn extends across the range from infrared to ultraviolet, but it is characterized by having a large peak at a wavelength of 4.4µm in the mid infrared range. The spectrum of a typical flame is shown [with other spectra] in Figure 1. Infrared rays are generated by low-temperature bodies, such as human, and by high-temperature bodies, but since they do not have the sharp peak of carbon dioxide gas resonance, the distinction of that peak can be used to detect that the radiation source is a flame.

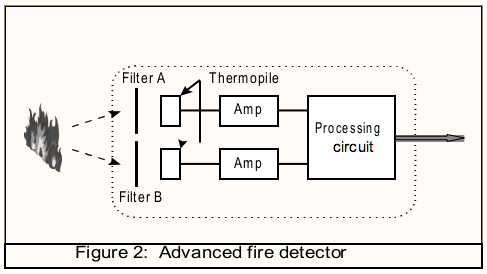

Configuration of a fire detector is shown in Figure 2. For the infrared light sensor, a pyroelectric type sensor, a thermopile, or other sensor is used. A pyro-electric type sensor utilizes the phenomenon that an electric charge is generated on the surface of a dielectric crystal when heat is applied to it. A thermopile is a row of thermocouples—specifically, a number of thermocouples are connected in a straight row in order to increase the sensitivity and has essentially flat wavelength characteristics. A first band-pass filter for [the wavelengths of] carbon dioxide gas resonance is placed in front of one sensor and a second different band-pass filter is placed in front of another sensor, and the strength of the infrared light reaching each sensor is detected. In the processing circuit, the ratio of the two strengths is measured and by the fluctuation it is determined whether the flame is being disturbed.

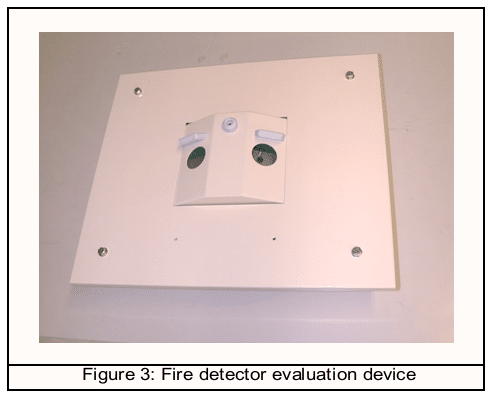

In addition, optimizing these parameters according to the use conditions, very precise fire detection can be done. Figure 3 shows an external view of the evaluation device. In both the left and right light receiving portholes, several sensors are mounted, and the device is configured so that the outputs and internal processing status can be monitored.

Combination to Networks

When a fire occurs inside a home, the important factors that help to minimize damages are: quick detection and notification. So essentially well-connected sensors will be a better design.

The sensors can be RF based or Wi-Fi network enabled. Provided Wi-Fi hot-spot must be on ground where fire can’t reach.

This kind of combination sensor, in addition to a fire detection function based on conventional infrared detection, has a relatively high degree of usefulness. Making a suitable DIY design can lead to a line of economical products and safety for all people. Hope this paper caters to designers who need system planning and make DIY deployable sensors.

Author: Kaushik Hazarika. He is an embedded project consultant and inventor of a low-cost LED inverter.