Choosing appropriate components is crucial for designing Drones with desired specifications

Unmanned aerial vehicles (UAVs), commonly known as drones, with their ability to access remote locations, have quickly progressed from military to numerous non-military sectors (such as in aerial or video photography). Drones can be customised for such specific applications as high-temperature resistance to act as first responders in case of a fire.

In this article, we discuss some useful pointers that could help you save time and decrease cost if you are planning to build a custom UAV of your own.

Understanding the science and terminology

Educating yourself is of foremost importance, especially if you want to reduce your chances of redesigning. This includes learning how flying becomes possible, different associated terminologies, and what impact do various components, centre of gravity and weight have on flight of the drone. Besides, many drone development platforms and kits are also available commercially to assist you.

In simple terms, four forces act on any aircraft while flying: weight, lift, drag and thrust. Weight, due to gravitational force, needs to be balanced by lift for an object to fly or at least remain afloat. If pressure at the top is lower than pressure at the bottom, the aircraft moves in an upwards direction. The drone is therefore designed to be lightweight.

Thrust or forward velocity depends on the shape of various parts like wings. Drag force slows down the aircraft by acting in the opposite direction of motion.

Size

Size denotes the greatest point-to-point distance between two motors on a drone. When it comes to a drone, not only weight but size also varies from small to large based on requirements.

Cost of the drone always depends on its functionalities and application, regardless of size. Small sizes, say, below 600mm, are good to start with if you are still learning.

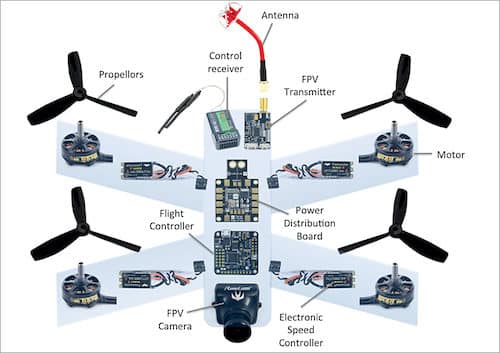

Selection of components

Choosing appropriate components is crucial to building a drone with desired specifications. A few tips for different components are mentioned in this section.

Frame

A frame is the basic skeleton of a drone for attaching all other components as well as providing protection. Commonly-known configurations include quadcopter (four arms), tri-copter (three arms), hexa-copter (six arms), octocopter (eight arms) and so on. Each arm is connected to a motor.

Besides configuration, material chosen decides durability of the drone. Such materials as plastic, carbon-fibre, PCB and aluminium are generally used. Though expensive, carbon-fibre is the best option as it is durable and lightweight.

- As a beginner, prefer relatively simpler quadcopter (x or +) or tri-copter frames, such as in DJI Phantom 2 Vision or Cheerson CX-33S. These frames can be rebuilt easily after crashing. Most flight controllers can work with quadcopter frames. Tri-copter frames, although cheap, need more work than quadcopters due to lack of symmetry.

- For commercial applications, a hexa-copter or octocopter is the way to go. These have more motors and larger batteries, and are ideal for lifting heavy loads. This implies that even if a motor or propeller fails, the drone can land safely.

- For smaller drones, you can utilise a 3D printer to get the right frame shape when working with plastic. PCB also works well for small sizes.

- While mounting the components, keep in mind that carbon-fibre hampers radio frequency (RF) signals.

Motors

Motors generate force to rotate the propellers and move through the air. The more efficient the motor, the longer the battery life and, hence, the flight.

- All motors should have the same thrust rating, usually given in grams, for ensuring stability.

- Some motors have performance comparison charts that can be utilised to make sure that the necessary target is met, especially in commercial drones.

- In large drones, brushless out-runner type motors (like FPVDrone 1104 motor) are used, while in smaller, inexpensive models, brushed motors are preferred. Unlike brushed motors whose brushes wear out quickly, brushless motors have longer lifespans, better durability and the ability to generate more power at low noise.

- Always check for kV rating in specifications. If you want the motor to spin faster, choose a motor with higher kV rating. Usually, a larger motor with lower kV rating has better efficiency and stability than a smaller one with high kV rating.

Propeller

Design of the propeller plays an important role in smooth propulsion and ensuring long flight times. A propeller can spin in either clockwise or anti-clockwise direction. Two- or three-bladed propellers are commonly seen in drones.

- Select propeller size based on the chosen motor to prevent overheating. A propeller is mounted on the motor so that the two can spin in sync with each other. Check that the propeller comes with adaptor rings as a backup option in case the propeller does not fit the motor.

- For a stable flying experience, large blades are ideal. But if you plan to change speed frequently, smaller blades are better.

- For beginners, chances of crashing are high, so using plastic is a good option due to its low cost. Just like for frames, if you want durability and high quality, go for carbon-fibre instead.

Wood is another alternative that can be utilised for toughness.

- Use prop saver and prop guard to keep the propeller in position and prevent it from coming in contact with the external environment in case of a light crash. While adding these, keep in mind overall weight.

Battery

Like most electronic devices nowadays, drones use high-cost lithium-polymer batteries as these are lightweight and provide high power.

- Use a battery with higher capacity (amp-hours) for more flight time. But remember, higher capacity means more weight. While starting, maximum flight time of fifteen to twenty minutes is suitable.

- The battery’s voltage must match that of the motor(s).

- Avoid safety issues. If the battery has not been charged properly, or it has been used for long enough for it to get discharged mid-air, it might burn. Also, there is a high probability of burning during a crash. Use a battery safety sack for prevention. You can use a battery beeper to inform when the battery is about to get discharged. Many commercial drones have a battery monitor to keep a tab on flying time and charge levels.

Electronic speed controller (ESC)

An ESC connects to the flight controller, motor and battery, and aids in controlling speed and direction of the motor(s).

- A power distribution board is used to share main battery power with different parts, and terminals so provided must be easy to solder to.

- The ESC provides the right voltage and handles maximum current consumption. Design the battery elimination circuit to convert DC voltage of the battery to DC voltage of the flight controller.

- Additional firmware can make the ESC more responsive to input changes.

Flight controller

This is the brain of the drone as it consists of microprocessors, sensors and I/O pins necessary to operate a UAV in air. Different sensors are used to obtain such information as height (barometer), speed, direction (compass), etc.

- Keep the flight controller near the horizontal centre of the drone to maintain the centre of gravity.

- Commonly-used sensors, including accelerometer (linear acceleration) and gyroscope (angular acceleration), help in providing stability while flying. These are contained in the inertial measurement unit (IMU) of commercial drones. With an increase in the number of sensors, cost increases, too.

- GPS helps in determining drone location at a specific point of time using satellites. Even when the drone flies away and is not visible, you can set the coordinates to which it should go for flying accurately. Set a home point so that the drone can return safely even if connection is lost.

Building the drone

After getting all components, start building the UAV.

- Improve your soldering skills if you are a beginner to ensure neat connections, higher reliability and less resistance. Ensure correct polarity while soldering.

- Insulate the electrical connections with insulation tubes to prevent short-circuits. Use heat to shrink the tube and, hence, insulate the components.

- Use hot glue for mounting components. Apply thread locking for connections that use bolts and nuts. This technique keeps connections together but, at the same time, components can be removed when needed.

- You can add LEDs to the drone to increase visibility at night.

- Use plastic, metal or rubber materials for landing to avoid any damage to components, especially for drones with payloads.

Flying

While flying, the transmitter or remote controller is used for controlling the UAV and standard receiver unit to catch signals. A good antenna can work at a larger distance. There are many options available in the market. Most remote-controlled drones use 900MHz for transmission.

- Use simulators (like RC Drone Flight Simulator 3D) to learn basic flying before doing an actual one.

- Know your country’s drone policy for operation by civilians and companies.

- First, fly only a little high in the air and check if motors are working. Never fly with a damaged or bent propeller. Inspect different parts and keep spare ones for backup.

- Take permission from nearby people before you fly. Arrange for a large open space where nothing could get in the way of flying the drone.

- Also, unless components are waterproof, do not take the drone out in rain, snow, etc, as it will damage the components. You can attach cameras (like, GoPro) if you wish to record the view in the final model.

- While self-levelling mode is easier for beginners, you should fly in acro or full manual mode to have complete control over the drone. You can use self-levelling as an alternate mode to avoid crashing.

Some cool features

Most ESCs allow propellers to spin only in a single direction. If you wish to rotate the propellers in both clockwise (CW) and anticlockwise (CCW) directions, use two different sets of propellers. You can also utilise firmware to configure these to fly in two directions.

You can also make the drone waterproof by using materials like carbon-fibre for arms and plastic for electrical parts.