The power of electronics was hardly realized before World War II. During that period and afterward, development in electronics technology took great strides. The emphasis during initial stages of development was on the use of electronics for communication. As a result of sustained efforts ‘hot’, electronics came into existence. At that time Vacuum valves were used to control the flow of electrons.

Then there was a spectacular and fast development. It brought semi- conductors such as a diode, transistors, integrated circuits (IC), light emitting diode (LED), liquid crystal display (LCDs) In due course of time many devices such as programmable logic controller (PLC), proportional integral derivative (PID) came into existence.

With reference to Indian situation, great importance was given to Research and development. Moreover, formal technical education in the field of electronics was given a boost. As a result of all these, innumerable types of machinery and plants are equipped with electronic systems of high order. Two examples are given below to highlight the view that there is a great scope for Electronics For You to dissipate knowledge to benefit readers and industry at large.

Thermoplastics Injection Molding Machines:

Around the year 1955 most of plastics Injection Molding Machines were operated and controlled manually. For example temperature of plastics heating cylinder was manually adjusted by a rheostat , movement of locking platern, injection piston was achieved by hand operated levers, there were hardly any safety gadgets. The result was an inconsistent quality of product and high percentage of rejects.

Present day machines are programmed to operate in manually, semi-automatic and fully automatic mode with precision control over time, speeds, temperature pressure etc. Most sophisticated machines are equipped with programmable logic control (PLC). In some specialized machine, even mold changeover is automatic. Many make and models are even equipped with Robotics to feed insert mouling or take out molded shots from between the mould halves.

Big Question: How does it become possible to achieve so complicated, highly precise and fully automatic working of machines?

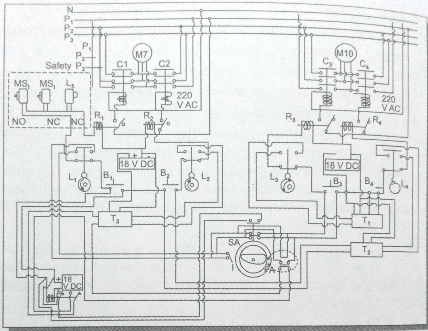

Simple answer: Electronics. Giving below an electrical cum electronics circuit to highlight the complications involved. It may be simplified by the use of latest electronic cum Electrical technologies.

Programmable Logic Control (PLC) :

PLC is a digital computer generally used in industry to control manufacturing processes, fully automatic machines, and robotics. It is made highly reliable, accurate, having fast response.

There are various types of PLCs to cater to the specific needs such as machine control, robotics and various types of industrial operations.. At the time of selection of a PLC, functional requirement must be clearly known. Next step may be to study specifications of various make and model. A photograph is given below; just to show how a PLC does looks like.

PLC manufacturers general provide many features as specifications, Few of them

are mentioned below

-

- Scan time

- System scale

- User interface

- Programing

- Number of Inputs and type

- Number of output and type

- Voltage supply

- Display type

- Memory size and

- Mounting type

There are a number of websites which provide online training for programmable logic control (PLC). The training program may include design, programming, installation, operation, maintenance and troubleshooting.

As far as Robotics is concerned, there are generally following four types of industrial robots for plastics injection moulding machines,

- Sprue pickers

- Pick and place

- Linear robot

- Six axis robot

These robots are built around Electronic sensors, PID and PLC

Electric Discharge Machining:

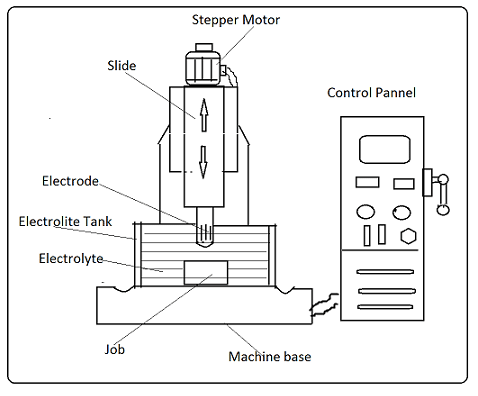

Machine is generally called, ‘Spark Erosion Machine’. It is a good example to highlight unavoidable use of electronics. This machine is very briefly described with the help of Figure 2 & 3

There are many functions of machine which are controlled by use of Electronics (loaded PCBs). Few functions are listed below.

- Fluid level in tank

- Electrolyte temperature

- Electrode touch indicator

- Touch retract

- Spark gap auto adjustment

- Spark current adjustment & auto control

- Rough/ fine finish adjustment

- Adjustment setting ‘Save’ control

- Stepper motor drive

- Synchronization card

- Electrode penetration depth adjustment

- Data storage and retrieval control

- Safety alarm

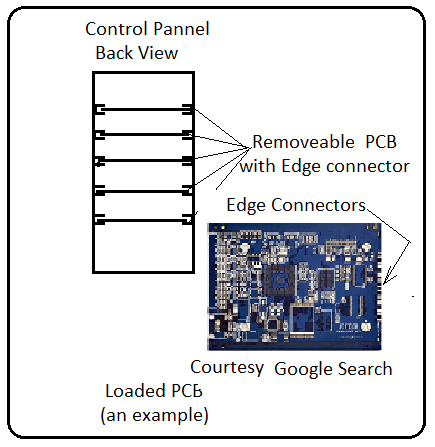

All above-mentioned actions are controlled by dedicated PCBs. Most of the PCB have edge connectors. This facilitates replacement of PCB in case loaded PCB become defective.

Machine users just change PCB and send defective one for repairs by specialized PCB repair service. Often EDM machine supplier handles this repair or replacement. Even recommend some party to carry out repairs. The objective of mentioning this is to highlight that electronics technology is indispensable. Knowledge dissemination is necessary through latest techniques such as eMagazines.