A renowned manufacturing firm incurred heavy monetary losses when clients returned 5000 units of its LED lights after discovering that the supplied units failed within a few hours of usage. On investigation, development engineers at the firm found thermal dissipation issues with MOSFET and SMPS, which were not taken care of during the design stage. The excessive heat led to the LEDs’ failure.

Thermal dissipation causes

The design of a system, coupled with judicial use of components, is crucial as it determines the product’s efficiency, and, in turn, thermal dissipation.

Pratik Mukherjee, vice-president (technology), SAR Group, recalls an incident where they had designed a sine-wave inverter with a totally different topology from other inverters. As the design was very sound, the company reaped its benefits and continues to do so even today. Although Mukherjee had to face a lot of criticism for the long time taken for its research and development, the product turned out to be a milestone for the company.

System over-usage and several applications running simultaneously also affect thermal dissipation. In a multi-functional design, several components of a system work simultaneously, which not only affects the other components but also increases heat dissipation. Components fail when these operate at temperatures exceeding the thermal level or junction temperature threshold.

Upcoming innovations

PCB manufacturers have been looking at various ways to reduce heat dissipation from their PCB boards, and make the end products efficient as well as durable.

To reduce thermal dissipation, a few upgrades have been introduced—from power supply and PCB routing to transformer and MOSFET manufacturing, and from solar cells in a panel to batteries in vehicles.

Power supply

Hrishikesh Kamat, CEO, Shalaka Technologies, says, “The design consideration, including the placement and calculative use of components, has a huge impact on thermal dissipation.”

Smartphone makers such as Micromax are ditching the traditional way of reducing thermal dissipation. For instance, in a mobile charger, a small and compact device, the voltage step-down process is followed by rectification to substantially reduce heat dissipation. Traditionally, the rectification process preceded voltage step-down in capacitive circuits, thus generating a larger amount of heat.

Kamat informs, “Most smartphone makers are using this technique to bypass heat issues, while a few are resorting to the use of ICs.”

Conor Quinn, technical marketing senior director, Artesyn Embedded Technologies, says, “Many of today’s power supplies use switching devices like MOSFETs or gate drivers, which are supplied in IC-style packages. Most ICs have in-built thermal protection and cut-off at a certain temperature before it hits the junction point.”

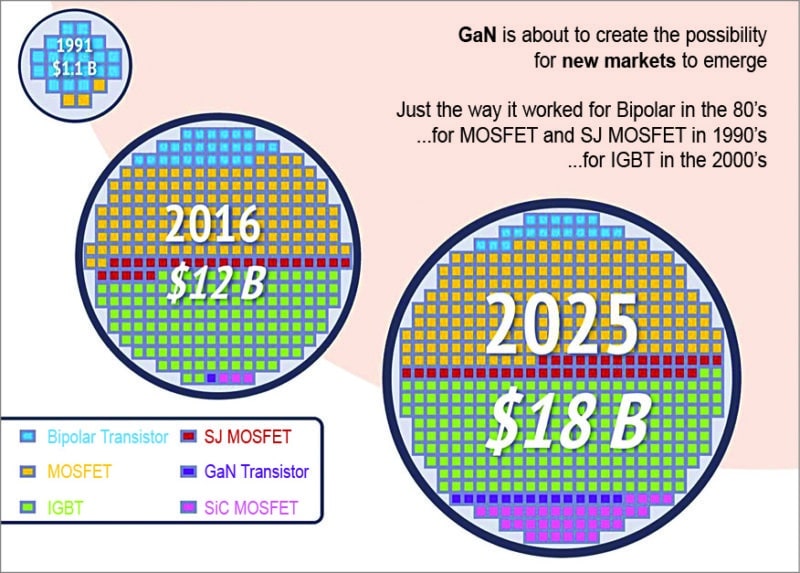

Both MOSFETs and transformers are being modified to improve their impact on heat dissipation. For instance, most power electronics manufacturers have started using gallium-nitride MOSFETs, which allow improved thermal dissipation due to high efficiency. Being used in high-frequency systems, these MOSFETs are taking the market by storm.

B.C. Bharadwaj, owner of Vedang Radio, informs that they are also using gallium-nitride FET in their RF power amplifiers as it helps to dissipate the heat well.

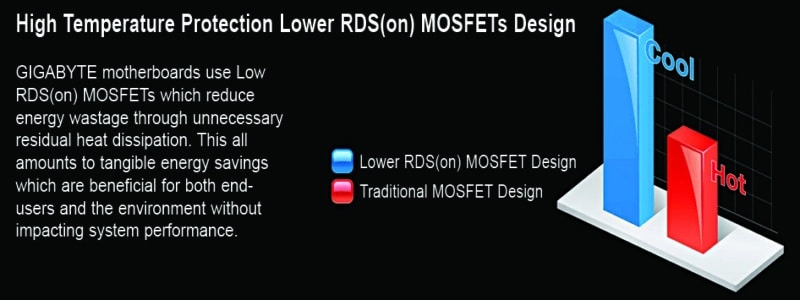

Besides, MOSFETs with low drain-to-source resistance (Rds ON) are now available for inverter applications. The lower the value of Rds ON, the lesser the power losses, which increases the inverter efficiency.

Mukherjee says, “The Rds ON value of the modified MOSFETs is one-fourth the earlier versions’. These MOSFETs are being used in inverters of SAR Group as well.”

Transformers

Transformer is the heart of a design. The transformer design affects the topology of the circuit design. For example, a transformer with flyback topology would increase the efficiency of a 50W LED bulb by reducing thermal dissipation considerably.

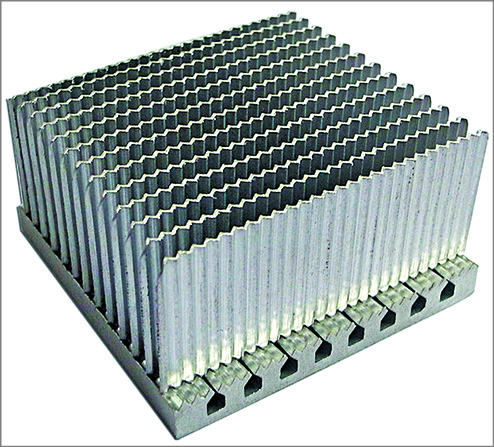

Heat-sinks. Heat-sinks are mechanical parts used in MOSFETs, ICs and diodes. These are mostly made of aluminium, which is cheaper and lighter than copper.

Thin metal sheet-based zipper heat-sinks are the new kids on the block. These are light in weight, and have a perfect profiling for proper heat dissipation. High fin density results in less surface area with improved properties. These heat-sinks are reliable and cost-effective too.

Battery-run products

PCB manufacturers are coming up with ways to improve the efficiency of battery-run products by decreasing the heat generated. One such product is e-rickshaw, which will soon be running on lithium polymer batteries as design engineers ensure better thermal dissipation mechanism in these batteries.

This can be explained better with ‘cranking phenomenon,’ in which a system starting with the power of a battery draws huge current initially, thus generating thermal stress in the system. This is the current concept in products such as e-rickshaws.

Besides, battery weight and efficiency are also being worked upon to combat thermal dissipation. Designers are working towards reducing the dead-weight of the battery (the weight of the charged battery), thus improving battery efficiency and life. The higher the efficiency, the lesser will be heat dissipation issues.

In this quest, they have come up with lithium polymer batteries, which will be a boon to the industry and consumers alike. These batteries support innumerable charge/discharge cycles, and will find application in mobile products and electric cars.

Lithium polymer batteries use polymer electrolyte instead of liquid electrolyte. Their composition is such that it improves heat dissipation, even during charging and discharging of the battery. However, the cost of the battery can be an issue as, Kamat says, these batteries will be four times costlier than the existing lithium-ion batteries.

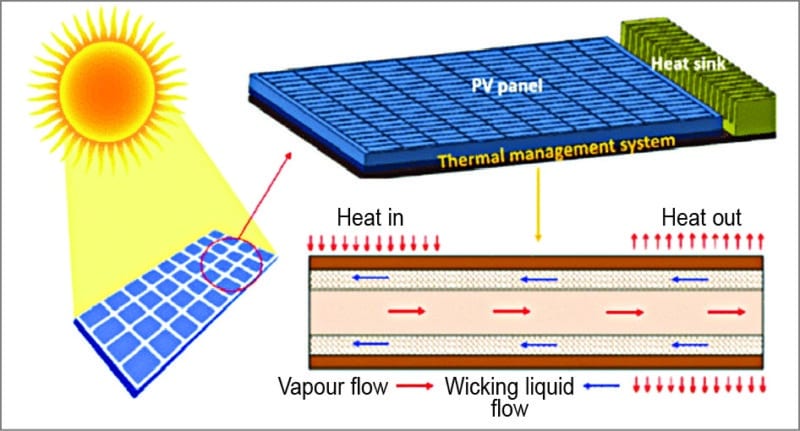

Solar cells

A solar panel is a system made from innumerable solar cells, which are basically diodes. During conduction stage, these diodes emit heat, which affects the efficiency of the end-product.

To resolve the heat dissipation issue, solar panel designers have switched from silicon to cadmium-telluride in solar cells, which has increased their voltage range, thus ensuring lesser heat dissipation and higher efficiency.

“Solar cells are following the industry standards, which claim around 17.3 per cent efficiency for each cell,” says Mukherjee.

Neglecting thermal issues: a costly mistake

The rise in heat can crash the expensive design or reduce the lifespan of the components or the system. More heat dissipation indicates flaws in the design as it is not able to manage heat issues. Realising this, designers across sectors are constantly working towards reducing thermal dissipation in their products, thus making their products efficient and long-lasting.