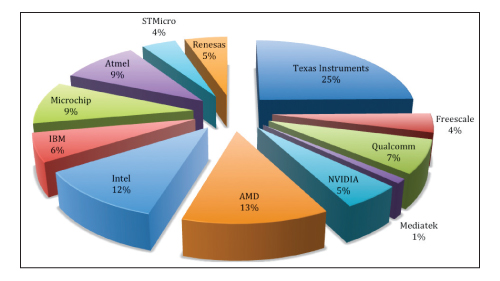

Pie chart of voting done amongst our online readers. The question was—which vendor would you buy a processor from, for your next embedded system?

Processor performance. Usually, we start this section talking about the clock speed, but we have learned that the instructions per second, operations per clock and the efficiency of the computation units are also equally important things to be considered.

“The most important parameter in my mind is cost vs performance ratio for a processor. The next important parameter will be the longevity of the product guaranteed by the manufacturer. These two parameters will ensure the cost-effectiveness and the longevity of the product getting designed using the processor,” advises Shanmugasundaram M., associate director-PES at Happiest Minds Technologies.

The instructions per second give you an idea of the computation power for large computers, whereas a higher operation per clock means a computer that might have lower clock speed could still perform competitively. Current processors have multiple cores and GPUs on the same die, which provides enhanced performance without sacrificing on power consumption or thermal design power (TDP). Benchmarking your shortlisted processors with a trial run of the application code is a good way to see if it meets your requirements.

The hardware acceleration feature in a processor is useful to speed up tasks with less software involvement. “It enables the multiprocessing option. The desired performance may be achieved by either a processor with higher processing power or with a slower processor accompanied by a set of hardware accelerators. Both approaches have their pros and cons. The merits and demerits of each of the approach would have to be evaluated against assigned weightage for the product requirement,” explain Vijay Bharat S. and Sachidananda Karanth-lead architects, Mistral Solutions.

“We have to consider that by doing hardware acceleration of certain modules, expandability might become a trade-off. Consider the example of today’s processor chipsets having hardware acceleration for H.264 video paired with a ARM9/11 processor core for other processing. These chipsets are not usable for upgrading to the next generation codec—HEVC, because of the trade-off done when the CPU selected was considering H.264 hardware acceleration use-case only,” explains Saravanan T.S., marketing, Semicon & Multimedia, Tata Elxsi.

Industry requirements. Such industries as automotive and medical have a different set of requirements for electronics designed for them. In a car, mission critical systems, such as the engine and safety systems, have stringent standards that are defined by organisations like the International Standards Organisation (ISO) and the Automotive Electronics Council (AEC). The factories have to be ISO certified, while the components and systems made from these factories have to adhere to AEC guidelines. Examples are the ISO/TS16949 safety standard and the AEC-Q reliability guidelines, which include AEC-Q100, Q101 and Q200 documents.

“Additionally, operating temperature range matters since many embedded applications are deployed in harsh environments where temperature shocks are present and thermal performance of processors (and other components) can make or break the solution,” explains T. Anand, managing director of Knewron.

The quality management standard for medical electronics is set by the ISO 9001:2008 and ISO 13485:2003 standards. In the US, the FDA 21 CFR Part 820 is a standard pertaining to good manufacturing processes for medical devices. The devices are also classed separately depending on their target application—toothbrushes go into Class I, infusion pumps and stents go into Class II while an implantable heart pump would go in Class III. The ISO 14971 standard specifies the process of risk management for medical device manufacturers.

Certain embedded applications like medical electronics require high levels of safety. “Applications like a media player require hardware acceleration to play media files. Applications in wireless communications require high levels of security. Storage and networking applications require high expandability. In essence, the priority of the functional requirements is driven by the domains and the application itself. What is important to an application is not necessarily important to another application,” adds Nate Srinath.