As the capacity of multi-layer ceramic capacitors increases, the number of cases in which multi-layer ceramic capacitors are being used in areas that were previously unconsidered is also on the increase.

In the marketplace, we are seeing practical applications being promoted to improve the efficiency of mainly electric power converters as a result of higher frequencies being applied to switching elements and these elements being driven at higher temperatures. In addition, multi-layer ceramic capacitors are being adopted more and more for their impedance characteristics at high frequencies and compatibility at high temperatures.

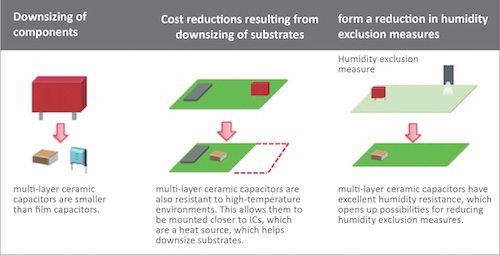

Another key point in their adoption is that downsizing and cost reductions can be achieved due to their compatibility with surface-mounted products.

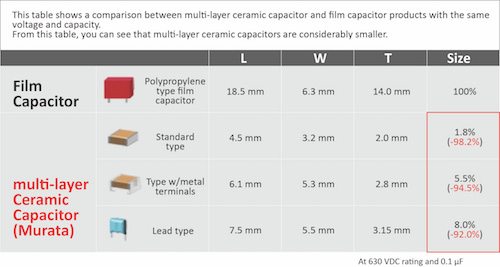

These materials provide actual examples of the differences between film capacitors and multi-layer ceramic capacitors, and how downsizing and cost reductions can be achieved.

Please do read our tips for increasing your design freedom.

Key reasons for recommending multi-layer ceramic capacitors

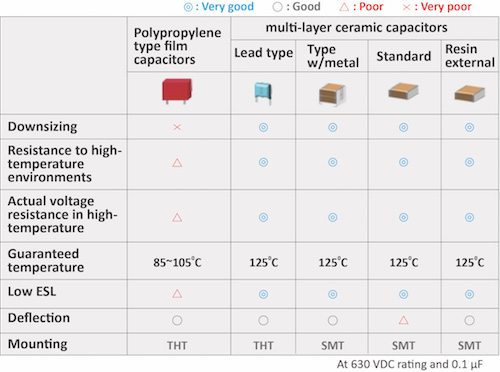

1) Downsizing is possible

2) Compatibility with high-temperature, high-humidity environments

3) Surface-mounting compatibility

1) Downsizing

2) Resistance to high-temperature environments and high humidity

With multi-layer ceramic capacitors, 125°C is set as the standard guaranteed temperature.

Also, we have tested our products for humidity resistance in high 85% or 95% humidity environments in reliability tests.

Content guaranteed under standard temperature environments

Reliability items in high humidity environments for general multi-layer ceramic capacitors

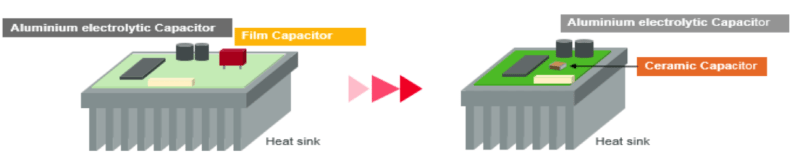

3) Surface-mounting compatibility

There are a number of advantages in choosing multi-layer ceramic capacitors: Components can be downsized, substrates can be downsized as a result of the high degree of freedom in the layout of mounted components, and humidity exclusion measures can be reduced as a result of their outstanding humidity resistance.

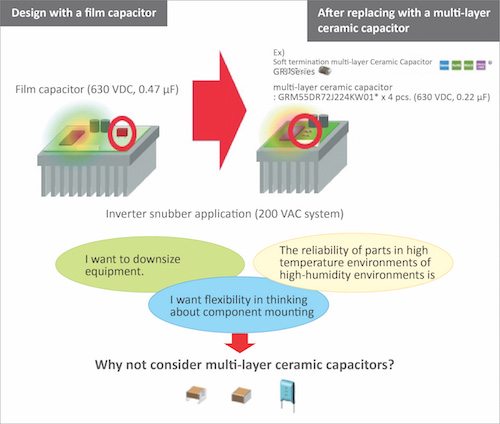

Example of replacement with a multi-layer ceramic capacitor (general-purpose)