Electromagnetic radiation (microwave). Rectenna is the key component of wireless power transfer by radio waves. It is a combination of a rectifying circuit and an antenna. The antenna receives the electromagnetic power, which is converted into DC electric power by the rectifying circuit.

A simple rectenna can be constructed from a Schottky diode placed between the antenna dipoles. Schottky diodes are used because these have the lowest voltage drop and highest speed and therefore waste the least amount of power due to conduction and switching.

Since portable devices have small dimensions, the rectenna too should be small in size. A small antenna area results in a low amount of received power, which is a huge drawback. Because of these limitations, wireless power transfer using radio waves is mainly suitable for low-power applications like low-power wireless sensors.

Wave coupling. WiTricity (evanescent wave coupling) is a technique that has recently been investigated by MIT researchers.

It basically extends the principle of magnetic induction to mid-range applications up to a few metres. The main differentiator is the use of resonance. If the sender and the receiver have the same magnetic resonant frequency, energy can be efficiently transported while losses to the non-resonant environment are extremely small in comparison. Using resonance, for the same geometry, power can be transported approximately a hundred times more efficiently than without resonance.

One of the benefits of WiTricity is that since most common materials don’t interact with magnetic fields, obstructing objects do not have much influence on the passage of WiTricity. The same goes for human tissue as well and hence health risks are low. The coils used for WiTricity are too large to be used in a cell phone, but the receiving coil can be reduced in size. According to the researchers at MIT, the transmitted power can be kept constant if the size of the sending coil is increased to keep the product of the sizes of both coils equal.

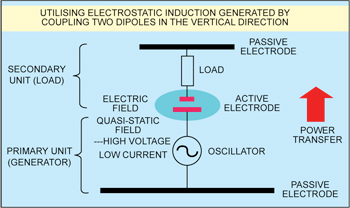

Electrostatic induction (capacitive coupling). In capacitive interface, the field is confined between conductive plates, alleviating the need for magnetic flux guiding and shielding components that add bulk and cost to inductive solutions. The realisable amount of coupling capacitance is limited by the available area of the device, imposing a design constraint on contactless power delivery.

Parallel-plate capacitance across a 1/4mm air gap is only 3.5 pF/cm2, limiting typical interface capacitance to a few tens of picofarads. The required charging power is upwards of 2.5W (USB-specification). Existing capacitive power transfer (CPT) solutions either use much larger capacitors or are targeted at lower-power applications, such as coupling of power and data between integrated circuits, or transmission of power and data to biosignal instrumentation systems.

Murata’s capacitive-coupling wireless power transmission modules have two sets of asymmetric dipoles consisting of active and passive electrodes positioned vertically on the power transmitting and receiving sides. Power is transmitted utilising an induction field generated by coupling of the two sets of asymmetric dipoles. This configuration realises wireless power transmission with high position freedom and efficiency.

Applications

Wireless charging of consumer electronics. Automatic wireless charging of mobile electronics (laptops, phones, game controllers, etc) in homes, cars, offices and Wi-Fi hotspots is possible. Direct wireless powering of stationary devices is also facilitated, thus eliminating custom wiring, wall-wart power supplies and unsightly cables.

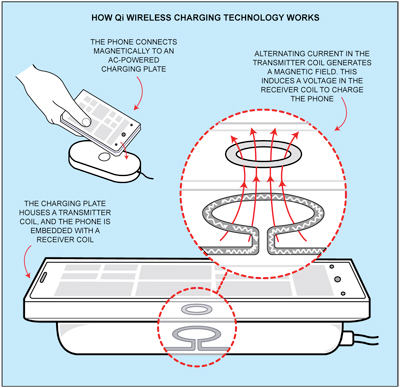

Wireless charging is done using an electromagnetic field to transfer energy between two objects via a charging station. Energy is sent through inductive coupling to an electrical device, which then uses that energy to charge batteries or run the device.

Wireless chargers typically use an induction coil to create an alternating electromagnetic field from within a charging base station. Another induction coil in the portable device takes power from the electromagnetic field and converts it back into electrical current to charge the battery.

Wirelessly charging of electrical vehicles. Researchers at Korea Advanced Institute of Science and Technology (KAIST) have developed an electric transport system, named the Online Electric Vehicle, OLEV, in which the vehicles get their power from cables underneath the surface of the road via non-contact magnetic charging. The power source is placed underneath the road surface and power is wirelessly picked up by the vehicle itself. Once logistics is worked out for this idea, the day isn’t far off when charging vehicles without having to stop will become a reality.

The Qi standard

Qi (pronounced ‘chee’) is an interface standard developed by the Wireless Power Consortium for wireless electrical power transfer over distances of up to 40 millimetres (1.6 inches). The Qi system comprises a power transmission pad and a compatible receiver in a portable device. The mobile device is placed on top of the power transmission pad, which charges the device via magnetic induction.

Mobile device manufacturers that are complying to the standard include HTC, LG Electronics, Huawei, Motorola Mobility, Samsung, Nokia and Sony. They aim to create a global standard for wireless charging technology.

All in all

In this era of communications and connectivity, individuals have multiple technologies to support their day-to-day requirements. In this scenario of multiple gadgets, wireless power technology is emerging as a practical solution for portable devices. The predominant market for wireless power transfer is unarguably the consumer handheld market. Mobile equipment giants like Nokia, LG, Samsung, HTC and Mototrola have already become WPC Qi-compliant and offer compatible phones.

Pavan Pudipeddi, senior strategic marketing manager, Wireless Power and Battery Charge Management, Texas Instruments (TI), says, “At TI, we recognise the huge market available in the wireless energy domain. TI’s goal is to become the premier supplier of wireless power solutions in the industry. Our receiver chips integrate a low-impedance, fully synchronous rectifier along with a low-dropout regulator, digital control, and accurate voltage and current loops. Recently, TI’s bq51050B became the industry’s first Wireless Power Consortium (WPC) 1.1 Qi-compliant wireless power receiver with integrated direct battery charger. It enables a faster, more efficient way of charging smartphones, wireless keyboards and other portable electronics.”

The author is a tech correspondent at EFY Bengaluru