Attaining ‘zero defect’ production requires a thorough knowledge of soldering technology. Here is a lowdown on the different kinds of techniques, material and equipment used in soldering

K. Bharathan

As defined in Digital Electronics by Tokheim, soldering is the process of joining two metals together by the use of a solder alloy to form a reliable electrical path. This technique was first developed in ancient Egypt. Soldering skills are needed to assemble any electronic circuit. Faulty solder joints may cause failure of major equipment. It is therefore necessary to have high standards of workmanship in soldering.

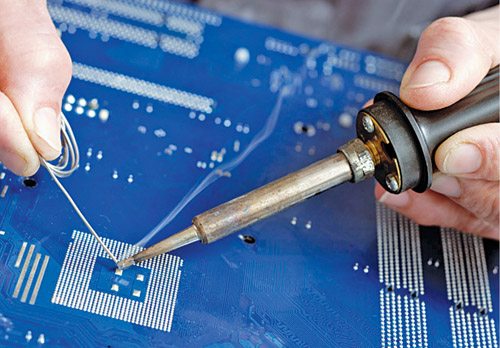

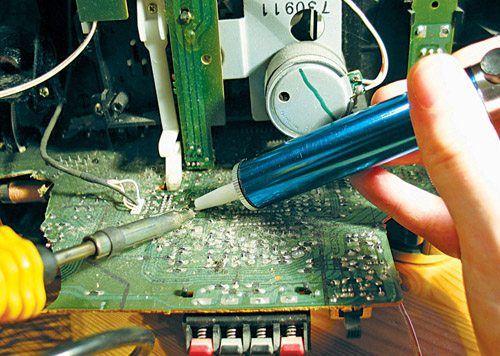

Soldering iron

A soldering iron consists of three main blocks: a resistance-heating unit, a heater block that acts as a heat reservoir and a soldering tip (also known as a bit). Soldering irons come in a variety of sizes, shapes and wattage. The wattage varies from 15W to 100W. The advantage of using a high-wattage iron is that heat can flow quickly into a joint and soldering can be done rapidly.

The temperature of the soldering bit depends on the mains input voltage. When using a soldering iron, some points to remember are:

1. Before using a soldering iron, clean the bit by wiping it on a wet sponge.

2. The surface of the bit should be constantly tinned to ensure proper heat transfer and to prevent impurities from entering the solder joint.

3. When the iron is not in use, keep it in a holder, with the bit clean and coated with solder.

In temperature-controlled soldering irons, a small magnet, which forms a part of the tip, activates a temperature-controlled magnetic switch. The magnet is designed to lose its magnetic properties at a predetermined temperature and the switch turns power to the heater ‘on’ or ‘off,’ controlling the temperature of the tip.

Another version of this soldering iron has an inbuilt temperature sensor. The power to the heater is turned on or off automatically to maintain the bit at the set temperature. Most soldering irons work off 220-240V AC mains. Soldering irons with low voltage operation (12V DC or 24V DC) generally form part of a soldering station, and are designed to be used with a special controller.

Bit. Soldering iron bits are available in different diameters and shapes. These can be changed depending on the type of work. Often, bits are either bright-plated or made from unplated copper to prolong their life. The bit should be cleaned periodically to prevent a layer of oxide from accumulating between the bit and the heating element. A bright tinned surface must be maintained at the working surface of the bit. Proper use and care of the soldering iron bit prolongs the life of the bit and prevents solder-joint failure.

Solder

Solder is an alloy of tin and lead in different proportions. It is usually available in the form of wires of different sizes and grades. The grades of solder refer to the percentage of tin to lead as 60/40 (indicating 60 per cent tin content and 40 per cent lead), 50/50 and 40/60. The most commonly used solder for hand soldering in electronics circuit assembly is 60/40 with non-corrosive flux cores.

Like electric wires, soldering wires are specified in gauges. Solder of 18 Standard Wire Gauge (SWG) is used for general purposes. Thinner soldering wire of 22 SWG or 24 SWG is used for printed circuit assembly.

Flux

Perfect solder joints can be accomplished only with properly cleaned soldering surfaces. The flux present in multicore solders is a chemical for removing the oxide film deposited on the surfaces to be joined. The corrosive action of flux at melting temperatures removes metal oxides very fast. It also prevents reformation of new oxides, which allows the solder to form a rigid bond. Flux helps molten solder flow more easily over the joint.

Flux melts at a temperature lower than the solder temperature. Thus it performs the task of cleaning the surfaces before soldering takes place. A variety of flux are available for many purposes and applications. The most common types specified by rosin content are ‘no clean,’ rosin mildly activated, rosin activated and water soluble. Flux consists of natural or synthetic rosins. Flux used in hand soldering are either pure rosins or rosins combined with mild activators.

Key to good soldering

Cleaning of the surface, soldering at the right temperature and for the right duration, and adequate solder coverage are the key factors affecting the quality of solder joints.