Most of the systems are powered by AC mains. Uninterrupted power supply systems (UPSes) are there as a back-up to power the systems when mains supply is interrupted due to a power cut. A UPS differs from a standby generator in that it will provide near-instantaneous power by supplying the energy stored in batteries. In an online UPS, batteries are always connected to the inverter, which is always on, so that no transfer switches are necessary when power disruption occurs.

Most of the systems are powered by AC mains. Uninterrupted power supply systems (UPSes) are there as a back-up to power the systems when mains supply is interrupted due to a power cut. A UPS differs from a standby generator in that it will provide near-instantaneous power by supplying the energy stored in batteries. In an online UPS, batteries are always connected to the inverter, which is always on, so that no transfer switches are necessary when power disruption occurs.

In an offline UPS, the inverter circuit is switched on when mains are not there. UPSes are available off-the-shelf, and one can select the system as per one’s requirement, back-up time being one requirement. However, one can construct a UPS of one’s own choice. Here is a circuit of a mini offline UPS, which a hobbyist can make at a reasonable cost. The capacity of the UPS is 350VA, so it can be used for any equipment with a load below 350VA. The UPS can be upgraded to 1kVA by making just a few changes.

Mini offline UPS circuit

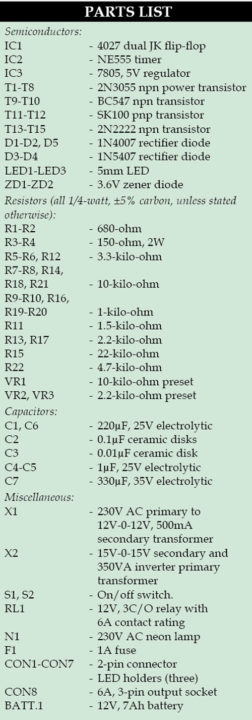

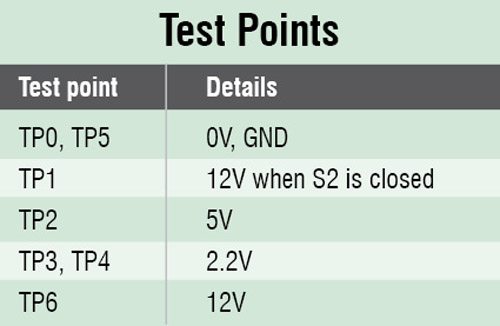

The circuit diagram of the mini offline UPS shown in Fig. 1 has the following four sections:

Section 1: Mains/inverter change-over section

Section 2: Inverter section

Section 3: Battery-status-indicator section

Section 4: Oscillator section

Above-mentioned sections and their interconnections are appropriately marked in the circuit diagram.

Mains/inverter changeover section. The circuit of this section is built around step-down transformer X1 (230V AC primary to 12V-0-12V, 500mA secondary), a 12V DC, 3C/O (changeover) relay (RL1) and a few other components. 230V AC mains is connected to the circuit through connector CON7. Output of the UPS is available at connector CON8, which is actually a 3-pin socket.

Mains voltage is rectified by diodes D1-D2 (1N4007)

The full-wave rectified output is smoothened by capacitor C1. DC voltage so generated is applied at pins 10 and 11 of relay RL1. When mains voltage is there, the relay gets energised to affect the changeover to connect the mains to the output of the UPS.

The circuit is not on a PCB and has been wired externally. Relay contacts in the circuit diagram are shown in a de-energised state of the relay.

Inverter section

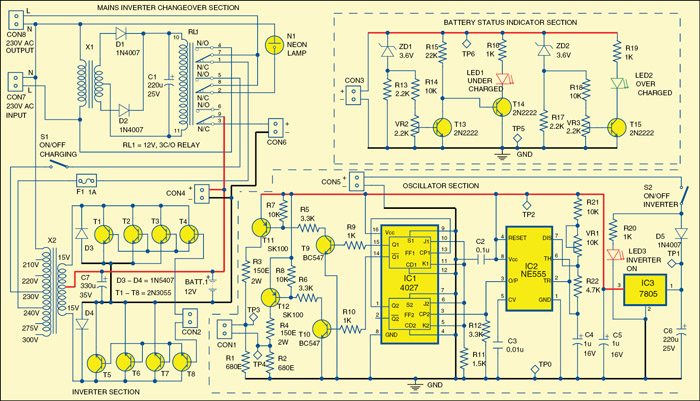

This section comprises transformer X2, npn power transistors 2N3055 (T1 through T8) and power diodes 1N5407 (D3-D4). Transistors, which are eight in number, are connected in two banks. The number of transistors per bank will depend on the required VA rating. The prototype has been made for 350VA rating by using four transistors per bank. The number of transistors required per bank for different capacities are:

550VA – Five

650VA – Six

1000VA – Seven

This circuit is also not on a PCB and has been wired externally. Transistors T1 through T8 have been fitted on the same heat-sink. Mounting of transistors has to be done in such a manner that their base and emitter are not in contact with the heat-sink. The metal body of the transistor is the collector. Collectors should be separated from the heat-sink. This is done by using mica separators between the heat-sink and metal body of the transistor. In short, all three terminals should be separated from the heat-sink. The arrangement is shown in Fig. 2.

Interconnections of transistor terminals, transformer X2, diodes D3-D4, battery-status-indicator section and oscillator section are shown in a combined circuit diagram (Fig. 1). The heat-sink should also be isolated from the UPS box.

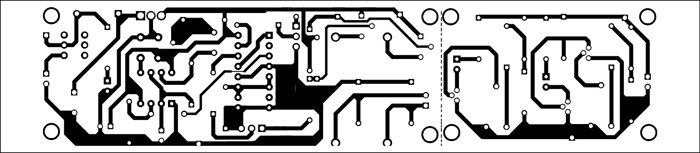

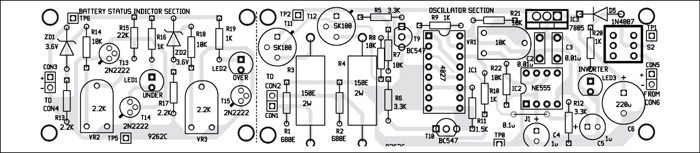

Download PCB and component Layout PDFs:Click here

Battery-status-indicator section. This section monitors the state of the battery. It is connected to the battery by CON3-CON4 combination. Connect these as per polarity of the 12V battery. Overcharge status of 14.4V is set with the help of preset VR3. Overcharge status is indicated by LED2.

We have to switch off S1 to protect the battery from overcharging. During normal charging, no LED (LED1 or LED2) will glow. If S1 is off, the rectifier circuit formed by diodes D3 and D4 will be disabled, which, in turn, will stop further charging of the battery. Lower limit of the battery is set at 11.3V with the help of preset low level of the battery, which will be indicated by LED1. Switch S1 has to be closed to restart the charging of the battery. Load should be disconnected when battery voltage is lower than 11.3V and mains voltage is not there.

Oscillator section

This circuit comes into action when mains voltage is not there. It, along with two banks of transistors T1-T8, will generate low-level AC voltage (15V-0-15V) at terminals of transformer X2, which will be stepped up by transformer X2.

The circuit is built around NE555 timer (IC2), dual JK flip-flop 4027 (IC1), transistors SK100 (T11-T12) and BC547 (T9-T10), voltage regulator 7805 (IC3) and a few other components. NE555 timer is configured in astable multivibrator mode.

Frequency of the timer is set to around 200Hz with the help of preset VR1 in order to get around 50Hz line frequency at CON1. Output of the timer from its pin 3 is fed to pin 3 (CP2) of second flip-flop of IC1 as clock pulse. Output of this flip-flop from pin 1 (Q2) is used to clock the first flip-flop. Outputs Q1 and Q1 are applied to the bases of transistors T9 and T10, respectively. Transistors T11 and T12 amplify these outputs to about 2.2V, which are applied to base terminals of transistors T4 and T8 for further amplification to 12V. Con1 and Con2 are used to connect outputs from the oscillator section to the two transistor banks.

The circuit is powered by a regulated 5V DC provided by voltage regulator 7805. Input to the regulator is the battery voltage, which we get by connecting Con5 to Con6. Battery voltage reaches pin 1 of regulator through pin 9 and pin 3 of relay RL1 and switch S2 is closed. When mains voltage is present, pin 9 and pin 3 are disconnected due to activation of the relay. Power supply to the oscillator section is interrupted, resulting in deactivation of the inverter circuit.

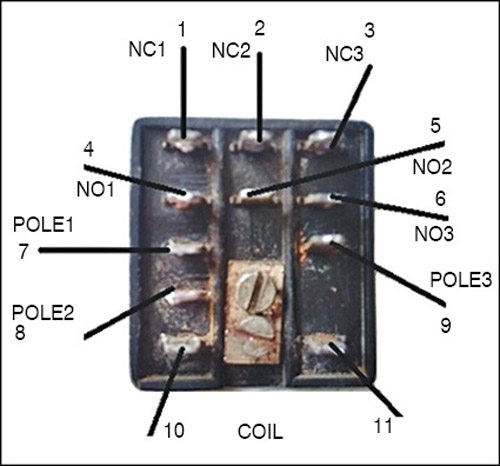

Relay RL1

Relay RL1 affects the necessary changeover required in the system due to the presence or non-presence of mains voltage. It is a 12V, three contacts changeover (three-poles double-throw) relay. The arrangement of poles and contacts is shown in Fig. 3.

The coil of the relay is between terminals 10 and 11. Terminals 7 and 8 are shorted. Connections of remaining terminals of the relay are shown in circuit diagram (Fig. 1).

Working of the circuit

The UPS works in two modes:

1. When AC power is present

2. When AC power is absent

When AC power is present

When AC mains power is present, transformer X1 gets 230V AC input mains supply. Relay RL1 is therefore energised. Terminals 7, 8 and 9 of the relay come into contact with terminals 4, 5 and 6, respectively. Phase of the incoming AC mains supply gets connected to terminals 4, 7, 5 and 8 of the relay and the output socket where we connect the load. In this manner, mains are transferred to output socket CON8 of the UPS.

When switch S1 is closed, the phase of the input mains gets connected to 230V tapping of transformer X2 through terminal 5 as it is in contact with the terminal 8 of the relay. As the neutral connection is common, transformer X2 acts as a step-down transformer. 230V AC is stepped down to 15V-0-15V AC and rectified to DC voltage by a full-wave rectifier (diodes D3-D4). Capacitor C7 is connected across the center tap of transformer X2. It is not included in the PCB. It is recommended to use a current limitter (say 4.7-ohm, 20W resistor) in series with positive terminal of the battery using suitable arrangement. The value of this current limitter will depend on your requirement, so it is not shown in the circuit here.

DC voltage so generated is used to charge the battery. At the same time, terminal 9 of the relay comes into contact with terminal 6, which disconnects power supply to the oscillator circuit and deactivates the inverter circuit. Switch S1 should be open when the battery is fully charged, which will be indicated by lighting up of LED2.

When AC mains power is absent(power cut)

When AC mains power is off, transformer X1 does not get 230V AC supply. Relay RL1 therefore does not energise. Terminals 7, 8 and 9 of the relay come into contact with terminals 1, 2 and 3, respectively. Terminal 9 is connected to the positive terminal of the 12V battery, which is extended to the oscillator circuit. Inverter circuit comes into action.

Transformer X2 is now a step-up transformer

AC voltage from 240V tap of transformer X2 is connected to terminal 1 of the relay. As terminals 7 and 8 are in contact with terminals 1 and 2 of the relay, 240V AC gets connected to output socket CON8. Neon lamp N1 is connected between terminal 2 and neutral. It glows when the UPS is on. The output is connected to 240V tapping because there will be a voltage drop when load is connected to the UPS.

Construction and testing

Combined single side PCB for the oscillator section and the battery-status section is shown in Fig. 4 and the component layout in Fig. 5.

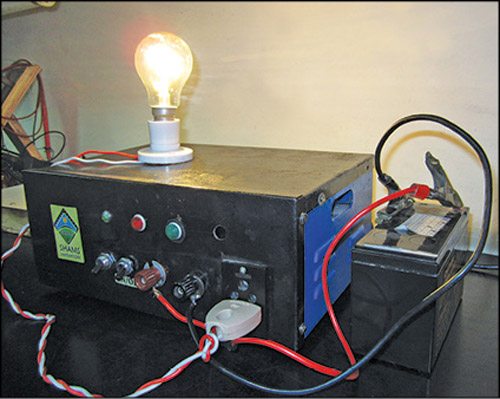

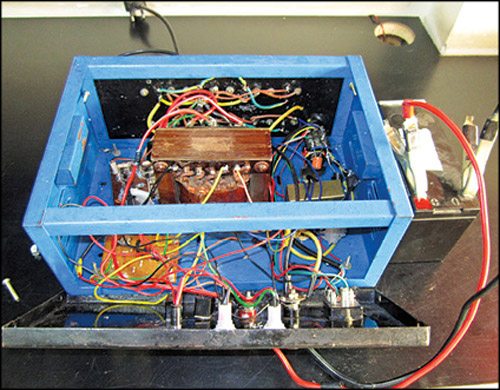

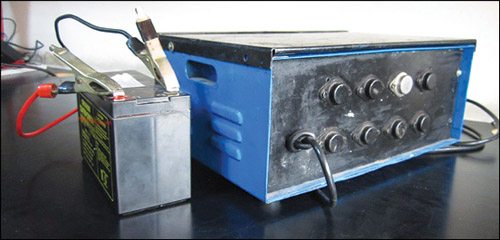

If needed, the PCB can be cut into two portions along the dotted line and mounted separately. Rest of the circuit has been wired using connectors. The final assemblage of the mini offline UPS is enclosed in a cabinet as shown in Fig. 6. The internal wiring is shown in Fig. 7 and the rear panel is shown in Fig. 8. All switches, indicators and terminals for connecting the battery and output socket are to be placed aesthetically on the front panel of the cabinet.

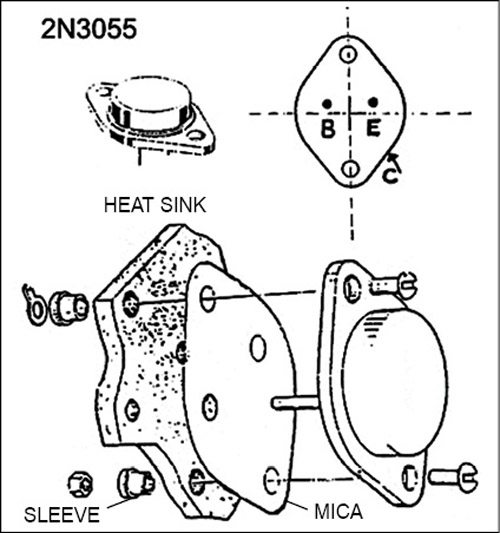

Fuse F1 (1A) is used to protect the device from any short circuits. All connections should be made very carefully. The load should not exceed 350VA. For troubleshooting, check voltages at various test points as listed in the table.

Caution

Please be careful as the circuit operates on 230V AC.

Best recipient

Is this circuit tested? Can I build the circuit exactly as described above and it would work?

Or are there any improvements you made to the UPS after testing?

Also are there any code needed for this desgin?

Kindest regards Tiaan

Dear Tiaan,

Thank you for posting your query in electronicsforu.com

Yes, It is tested in our EFYlab.

It should work provided your wiring is correct and proper

heatsinks are used.

There is no source code used in this project

Feel free to contact us if more queries.

Thank you.

Good day. I am following this project for a long time. Thank you very much. Is it possible to upgrade this project to 3600 watts output.