The LiDAR power solution employs a boost converter in Discontinuous Conduction Mode to deliver over 350V output, tailored for automotive applications and compliance with stringent standards.

The advent of autonomous vehicles marks a significant milestone in technological advancement, bringing what was once mere speculation into reality. These self-driving cars achieve remarkable levels of autonomy by integrating a suite of sensory technologies, including cameras, radar, and LiDAR. LiDAR, in particular, stands out for its use of light waves to measure distances, functioning like radar but with laser diodes and advanced photodiodes (APDs). However, this innovation brings a complex engineering challenge: developing a high-voltage power supply for the APD sensor, which is essential for its operation and must comply with stringent automotive standards, including cost-effectiveness and electromagnetic compatibility (EMC) regulations.

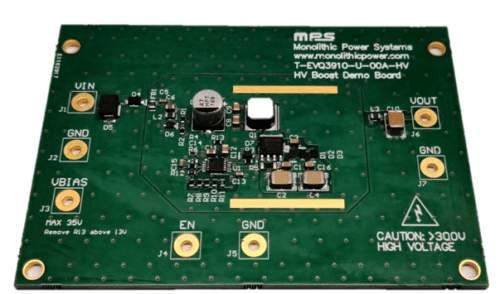

The reference design for LiDAR application from Monolithic Power Systems employs the MPQ3910A to manage a boost converter operating in Discontinuous Conduction Mode (DCM). Doing so addresses the challenges of LiDAR systems that operate at highly high-duty cycles, using cost-effective and compact components. The design cleverly doubles the boosted voltage using a charge pump, enabling it to generate over 350V of output. This is achieved while utilizing semiconductors rated for lower voltages, which are smaller and less expensive and offer superior performance compared to higher-voltage alternatives.

The design boasts a range of features that ensure its compliance and versatility in various applications. It meets the stringent standards of CISPR-25 Class 5, ensuring minimal electromagnetic interference. The device operates efficiently across a wide input range of 5V to 35V. It includes a single N-Channel MOSFET gate driver capable of delivering 12V at 1A. Users can configure the frequency anywhere from 30kHz to 400kHz, and it also supports an external sync clock ranging from 80kHz to 400kHz. The product features a configurable soft start mechanism, enhancing its operational stability. Safety measures include Over-Current Protection (OCP), Output Over-Voltage Protection (OVP), and Short-Circuit Protection (SCP).

An internal LDO is incorporated, with the option to connect an external power supply. For improved efficiency at light loads, it offers a pulse-skipping operation. The device is packaged in a compact MSOP-10 form and is AEC-Q100 qualified, affirming its reliability in automotive applications.

The MPQ3910A functions as a boost converter, designed with a 12V nominal input and capable of delivering an output of 300V at 15mA. It includes an EMI filter for reducing electromagnetic interference and features built-in polarity protection for enhanced safety and durability. The design is suited for applications in the automotive industry, particularly for powering Advanced Photodiode (APD) sensors in LiDAR systems, which are integral to autonomous vehicle technology.

Monolithic Power Systems has tested this reference design. It comes with a Bill of Material (BOM), schematics, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.