Reference design for a 22kW industrial motor drive for three-phase 400 V AC grids.

The REF-22K-GPD-INV-EASY3B can be used for both low-powered motor control as well as high-power applications.

The reference design REF-22K-GPD-INV-EASY3B from Infineon is an industrial motor drive for three-phase 400 V AC grids and has a nominal power of 22 kW. It includes a power module, current sensor, gate driver IC and a 1.7 kV SiC-MOSFET. The reference design can be used for both low-powered motor control as well as high power applications such as conveyor belt and compressors, etc. The reference design also features a software that enables full control and communication via touch screen and PC-GUI. The reference design can take 3ϕ input between 380 – 480 V and provide a wide range of output from 0 – 456 V with a rated current of upto 45A. The reference design is pretested and is highly customisable. The drive is suitable for a wide variety of applications such as motor drives, servo drives, UPS systems, pumps, conveyor belt, Air conditioning compressor, etc.

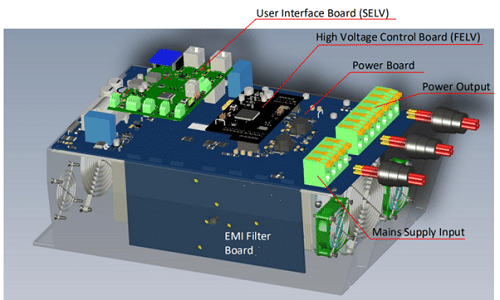

The reference designed can be divided into 5 separate boards: Power board, EMI filter, High-voltage logic board, Low-voltage interface board, DC-link board. This makes the reference design highly customisable with respect to specification and size. Furthermore, it allows for better isolation between different sub-systems making the reference design safer and more reliable.

The reference design uses two microcontrollers: one for control and one for communication. The communication microcontroller enables the touchscreen. The board also provides the capability to interface with external sensors, such as a high-resolution rotor speed sensor, high-resolution rotor angle sensor, temperature sensor, etc. The reference design is an air-cooled system employing up to 3 fans. The fans can automatically adjust cooling by adjusting the flow rate.

The AC voltage is rectified via the uncontrolled diode full bridge. The inrush current is limited by pre-charge circuitry. The rectified AC voltage is stabilized by a DC-link capacitor bank. The IGBT six-pack allows for the modulation of a three-phase output voltage/current which can be varied in terms of its amplitude and frequency. The reference design is suitable for both low-powered as well as high-powered applications such as driving machines, conveyor belts, lifts, etc.

The reference design can be divided into 5 separate boards: – Power board, EMI filter, High-voltage logic board, Low-voltage interface board, DC-link board.

Power board: The power board is used for powering all the other sub-boards. It houses the main DC-DC converter and the gate driver.

DC-link board: The reference design uses multiple electrolytic capacitors. The DC-link board is used to separately houses the capacitor thus allowing higher level of design freedom and a compact design of the inverter.

EMI-Filter board: The EMI filter board supress the RF noise generated during the operation.

High-voltage logic board (FELV board): This board can be considered as the brain of the reference design, all logic functions required to control the drive motor are implemented on the high-voltage (HV) logic board.

Low-voltage logic board (SELV board): This board take care of all the communication features of the reference design. It enables connectivity options such as EtherCat, USB 2.0, WLAN, Bluetooth, RS485 and High-Speed CAN.

This reference design has been tested by Infineon. It comes with required design resources such as Gerber files, schematics, BoM, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design click here.