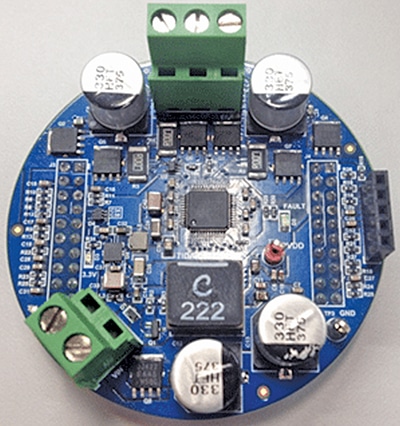

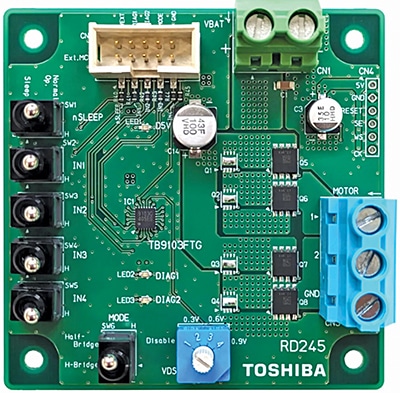

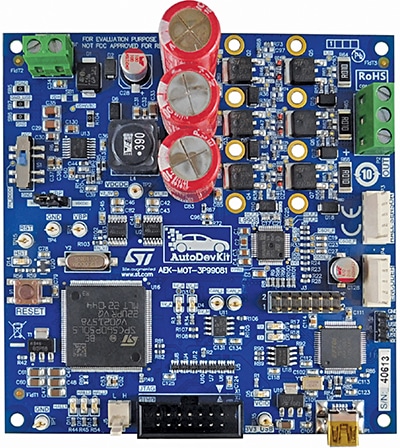

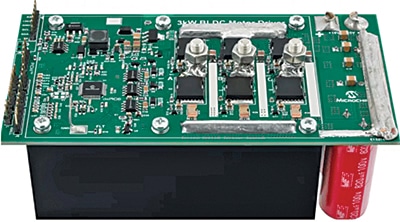

| Title of Reference Design | Automotive BLDC Motor Drive | Automotive Brushed DC Motor Control | Automotive Motor Control | Low Voltage BLDC Automotive Motor Control | Compact Automotive BLDC Motor |

| Image |  |  |  |  |  |

| Key Attractions | The reference design helps create 12V motor control systems with or without sensors. It handles motors up to 200W and offers features like noise reduction, long lifespan, and flexibility for different uses. | The reference design makes motor control easy and reliable, offering flexible options for driving motors safely. With built-in safety features, voltage protection, and stable power, it simplifies testing, making it suitable for automotive systems. | The reference design combines a microcontroller with analogue components in a compact package. With power management, interfaces, and debugging capabilities, it offers a solution for efficient, high-performance applications. | The reference design integrates motor speed detection, field-oriented control, and communication via CAN, offering a solution for motor management while ensuring safety and flexibility in operation. | The motor controller reference design handles power, controls torque and speed, and includes safety features, with communication options and support for motor control techniques like FOC. |

| Highlights | The TIDA-00901 reference design by Texas Instruments (TI) enables design engineers to develop 3-phase brushless DC motor control systems for automotive applications. It supports sensorless commutation and Hall sensor integration, allowing adaptation to various motor configurations. Capable of driving motors up to 200W and handling currents up to 20A, it is suitable for 12V systems. The design includes the DRV8305-Q1 gate driver for motor control, the LM56300-Q1 step-down converter for power management, the LMT86-Q1 temperature sensor for thermal monitoring, and the DRV5013-Q1 Hall effect sensor for motor position feedback. Engineers can use its wide supply range, reverse battery protection, and control interface to address application requirements. The design provides ease of use, reliability, and adaptability for automotive applications, enabling efficient operation, long service life, and reduced noise. | Toshiba’s reference design enables engineers to explore two motor control configurations: driving two motors in half-bridge mode or a single motor in H-bridge mode. Key features like dead time control, integrated fault detection, and fault indication outputs enhance motor reliability, safety, and durability. At the same time, the design’s wide input voltage range makes it adaptable to various automotive systems. The design simplifies evaluating and testing the TB9103FTG’s capabilities, allowing motor control via manual switches or an external microcontroller (MCU). A reverse connection protection circuit using the XPH1R104PS MOSFET safeguards against incorrect power supply polarity. An integrated voltage regulator IC ensures a stable 5V power supply for the design and external MCU. At the same time, the TB9005FNG enhances reliability with low-voltage reset, power-on reset, and a watchdog timer for optimal MCU performance. | The S32M276SFFRD is a reference design from NXP Semiconductors that incorporates the S32M276 integrated system, which combines a 32-bit ARM Cortex-M7 S32K3 microcontroller and an analogue component, including a voltage regulator, gate driver, and current sensor, within a single system-in-package design. The design includes interfaces such as UART and CAN with an internal PHY, RGB LED, JTAG 10-pin connector, faston connectors for power supply, and a 3-phase motor connection, and it operates with an external +12V/5A supply. The internal analogue extension handles the power management die within the SiP, distributing the power from the 12V supply, minimising BOM and conserving space. For MCU programming, it features JTAG connectors compatible with a PE Multilink universal FX debug probe, allowing users to control the target’s execution, debug code, and program memory. The microcontroller integrates a digital programmable gain amplifier for low-side current measurements, which includes a current sense amplifier, adjustable gain, blanking time counter, and over-current comparator. | The AEK-MOT-3P99081 evaluation board from STMicroelectronics supports encoder inputs and Hall sensors for motor speed detection and control. The drive system uses a field-oriented control (FOC) algorithm for operation. Controlled via a standard CAN command set from any domain or zone controller, the design simplifies the management of control loop bandwidth and resource demands. The CAN protocol enables data exchange, allowing commands to start or stop the motor, adjust its speed, reverse direction, and relay error notifications. Programming is possible via an integrated programmer/debugger or an external adaptor connected to the JTAG connector. The board includes a gate driver and a three-phase motor gate driver, with features for BLDC motor control, including current monitors for ground-referred currents. It also ensures safety with a power supply unit that protects against battery polarity inversion and power generation through a DC-DC converter and voltage regulators. | The dsPIC33CK64MP105 DSC motor controller reference design by Microchip Technology provides a platform for engineers to develop motor control systems with continuous 50A RMS and peak current up to 150A. It supports an 18V–85V input voltage range, suitable for up to a 20s battery pack, and features an XT90-type connector. Based on field oriented control (FOC) with Hall sensors, the system ensures precise motor torque and speed control. Integrated features, such as maximum torque per amp (MTPA) for IPMSM motors and field weakening (FW), extend the power range. The current sensing mechanism employs three 500µΩ low-side shunt resistors per phase and configurable PWM switching frequencies from 8kHz to 20kHz. Safety protections include overvoltage and undervoltage safeguards, motor phase overcurrent detection, and over-temperature protection on the inverter stage MOSFETs. The controller consists of CAN communication and auxiliary connections for throttle input, voltage monitoring, I2C, UART, and Bluetooth options for connectivity. |

| Applications | The reference design suits automotive applications, such as HVAC blowers, water pumps, eTurbo systems, radiator fans, and oil pumps. | The reference design is suitable for latching and driving motors like doors, seats, and windows in automotive applications. | The reference design is suitable for automotive BLDC and PMSM motor control applications. | The reference design is suitable for brushless motors in automotive applications. | The reference design is suitable for micro-mobility applications where space is at a premium. |

| OEM Brand | Texas Instruments (TI) | Toshiba | NXP Semiconductors | STMicroelectronics | Microchip |

| URL | Click Here | Click Here | Click Here | Click Here | Click Here |

Create an account

Welcome! Register for an account

A password will be e-mailed to you.

Password recovery

Recover your password

A password will be e-mailed to you.

Wednesday, December 17, 2025