The LED lighting control design boosts brightness safely and works independently or with remote triggering, serving various applications.

LED lighting control systems are vital in automotive applications for their ability to enhance energy efficiency, safety, and aesthetics. These systems optimise energy usage, improve visibility, and enable customizable lighting designs by dynamically adjusting brightness, colour, and direction. They also contribute to the longevity and reliability of LED lights while facilitating compliance with regulatory standards and integration with other vehicle systems, making them indispensable components in modern automotive lighting solutions. The TIDA-01081, an LED lighting control reference design by Texas Instruments (TI), introduces an innovative approach to power and manage high-power LEDs.

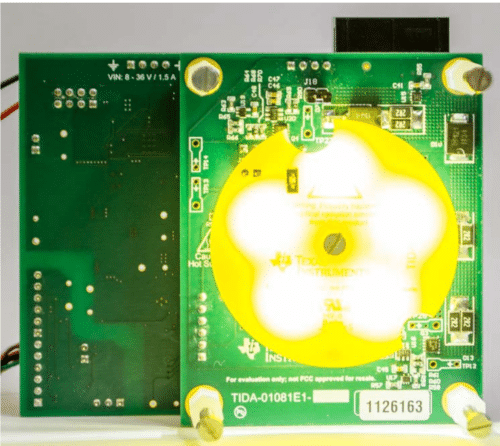

The design enables users to set the LED current and timing, allowing the safe overdriving of LEDs to achieve greater brightness. It can function independently, yet it also supports triggering or sends a trigger via an isolated interface. The design includes internal circuitry that accommodates a broad range of input voltages, allows for adjustable input current, and manages input power.

Lighting and illumination solutions are indispensable in various applications, such as machine vision and logistics. They are crucial for enhancing the performance of cameras, code readers, barcode scanners, industrial lighting, and automotive lighting systems. In machine vision and logistics, optimal lighting conditions are essential for accurate image capture and processing, enabling efficient object recognition and tracking. Similarly, proper lighting enhances visibility, safety, and productivity in industrial settings. In automotive applications, advanced lighting systems improve driver visibility, enhance vehicle aesthetics, and contribute to overall road safety. Whether it’s illuminating workspaces for industrial tasks or providing lighting solutions for automotive safety and aesthetics, these applications rely on efficient and effective lighting and illumination solutions to fulfil their functions.

This LED lighting control reference design reflects the prevailing market trend of employing high-power LEDs as primary light sources. It showcases the integration of a programmable constant current driver, capable of delivering up to 2.4 A, via a dedicated buck LED driver. With a strobe repetition frequency of up to 10 kHz and configurable pulse width down to 200 ns, it aligns perfectly with the demands of high-speed imaging applications. Utilising a digital-to-analogue converter (DAC), the output current of the LED buck can be finely tuned. Supervision the LED buck’s output voltage and temperature, and the buck inductor ensures protection against overvoltage and over-temperature conditions. The embedded temperature sensors also offer ample programmable EEPROM space for user data storage, enabling functionalities like board identification and parameter configuration.

Operating across an 8-V to 36-V input voltage range, facilitated by a pre-boost converter, ensures compatibility with various power sources such as 12-V, 15-V, or 24-V supplies. The regulated 48.5-V output from the pre-boost is the input for the downstream LED buck, with dedicated overvoltage protection circuitry ensuring operational safety.

TI has tested this reference design. It comes with a bill of materials (BOM), schematics, etc. You can find additional data about the reference design on the company’s website. To read more about this reference design, click here.